Technique and equipment for crystallizing nucleotide

A nucleotide and crystallization technology, applied in the field of nucleotide purification process and its equipment, can solve the problems of difficulty in controlling the nucleation induction period, high cost of production process, and failure to meet the demand, achieving better quality, convenient operation, good crystal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

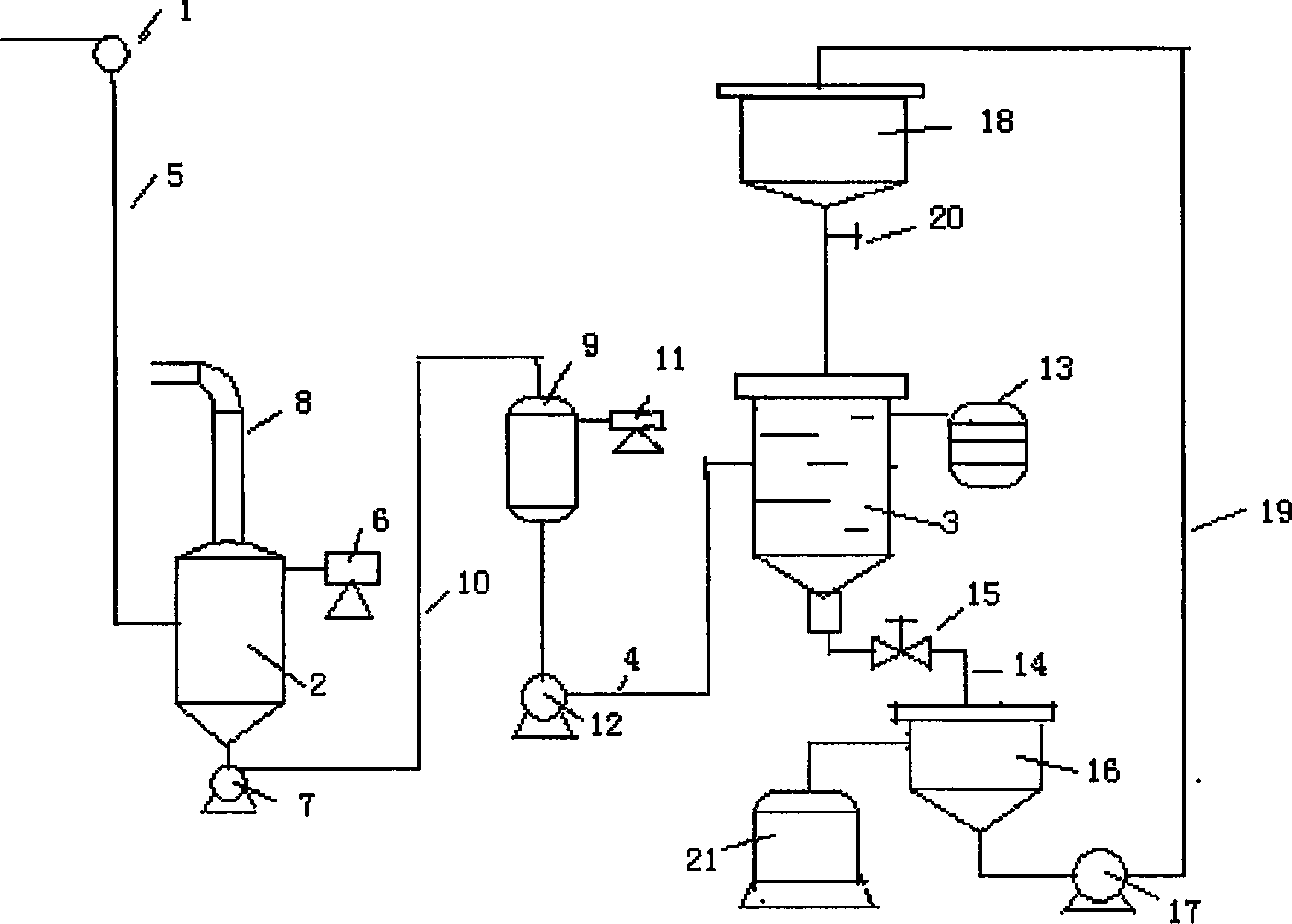

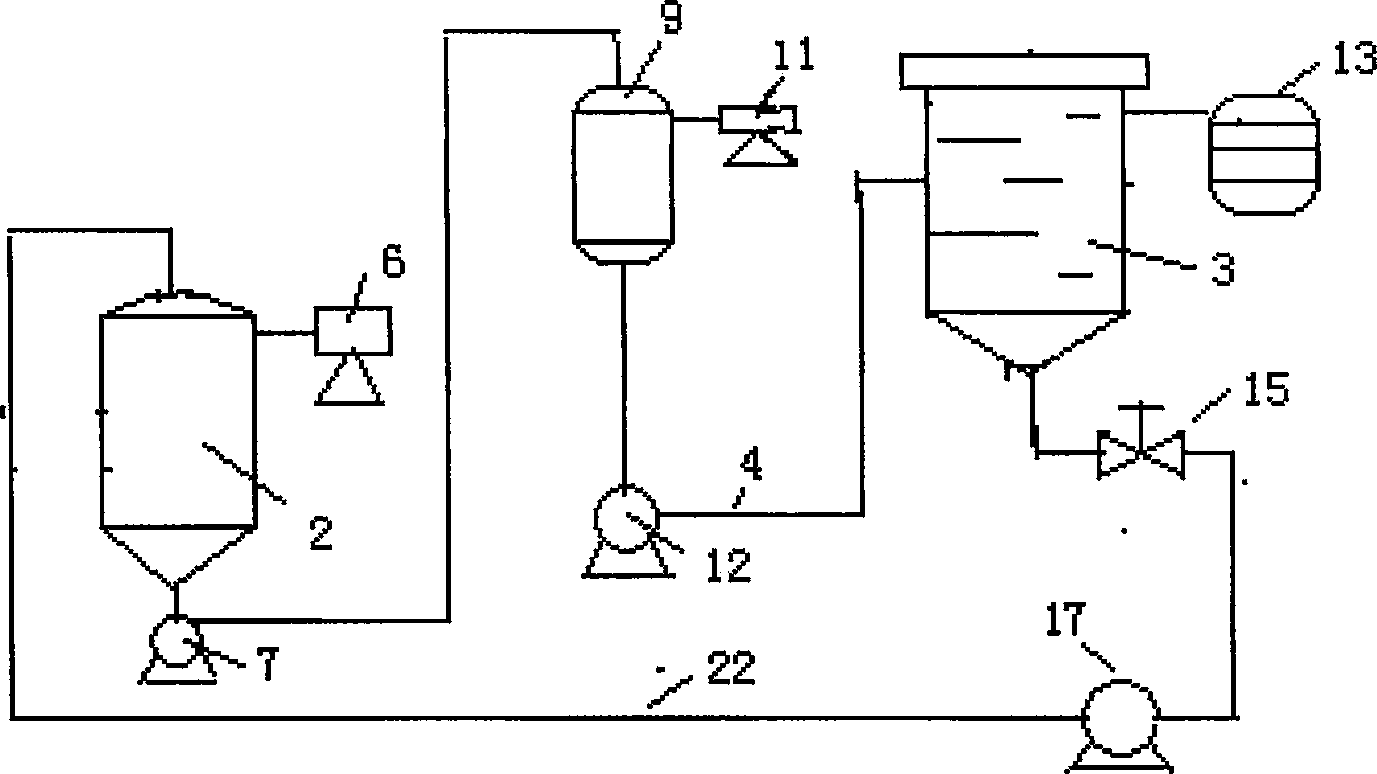

[0034] combined with figure 1 , firstly, the feed liquid containing only 5'-AMP with a concentration of 6g / l after separation and initial extraction is sent to the evaporator 2 with a capacity of 100L through the pipeline 5, and the vacuum is carried out at a vacuum degree of 695mmHg and a temperature of 38.1°C. Concentrated to 15.2g / l, the supersaturated solution is sent to the vacuum filtration device 9 through the heat preservation pipeline 10, and the vacuum degree of about 700mmHg can be controlled by virtue of the effect of the vacuum pump 11, and the concentrated solution after the suction filtration is passed through the heat preservation pump 12. The pipeline is introduced into a 500L crystallizer 3 with a constant temperature of 20.5° C. and a stirring rate of 100 rpm / min for solution crystallization. In order to maintain the concentration of the crystallization solution at 12 g / l, which is higher than the solubility at this temperature, the feed rate was controlled ...

Embodiment 2

[0037] combined with figure 1 , firstly, the feed liquid containing only 5'-CMP with a concentration of 20g / l after the initial extraction of ion exchange is sent to the evaporating concentrator 2 with a capacity of 100L through the pipeline 5, and the vacuum is carried out at a vacuum degree of 605mmHg and a temperature of 45°C. Concentrated to 40.2g / l, the supersaturated solution is sent to the vacuum filtration device 9 through the insulation pipeline 10, and the vacuum degree of about 700mmHg can be controlled by virtue of the effect of the vacuum pump 11, and the concentrated solution after the suction filtration is heated by the heat preservation pump 12. The pipeline is introduced into a 500L crystallizer 3 with a constant temperature of 24.8° C. and a stirring rate of 150 rpm / min for solution crystallization. In order to maintain the concentration of the crystallization solution at 35.8 g / l, which is higher than the solubility at this temperature of 5.2 g / l, the feed r...

Embodiment 3

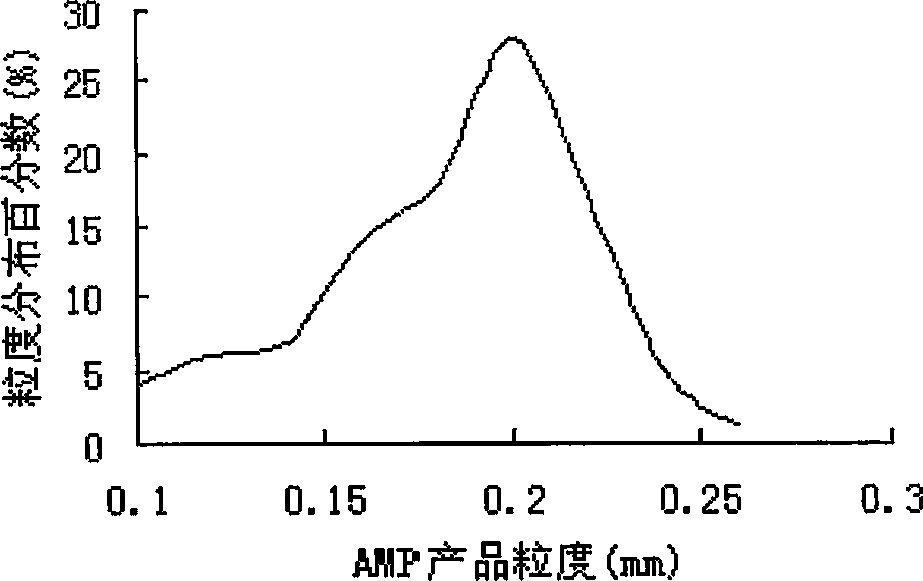

[0040] combined with figure 1 , if in the crystallizer 3, start to add suspension density to be 2.5g / L, particle size is the seed crystal of 0.08mm, concentrate to 16.8g / l in the vacuum evaporation concentrator, crystallize under the situation that crystallization liquid concentration maintains 10g / l , other operating conditions were the same as in Example 1 to complete the continuous crystallization of 5'-AMP. Embodiment 3 can also achieve the purpose of continuous crystallization of 5'-AMP, and the crystallization period is only 21.5 hours. Obviously, the quality of the crystallization product obtained in Example 2 is better than that of the product obtained in Example 1, because the whole crystallization process is based on induced crystallization, and the finished product particles are more uniform, and the average particle size is obviously increased, and the purity and yield are also high. Higher, the results are shown in Table 3, Figure 9 shown.

[0041] cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com