Method for preparing films of cobalt silicate

A technology of cobalt silicide and thin film, which is applied in the field of preparation of cobalt silicide thin film, and can solve the problems of poor thermal stability and limitation of thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

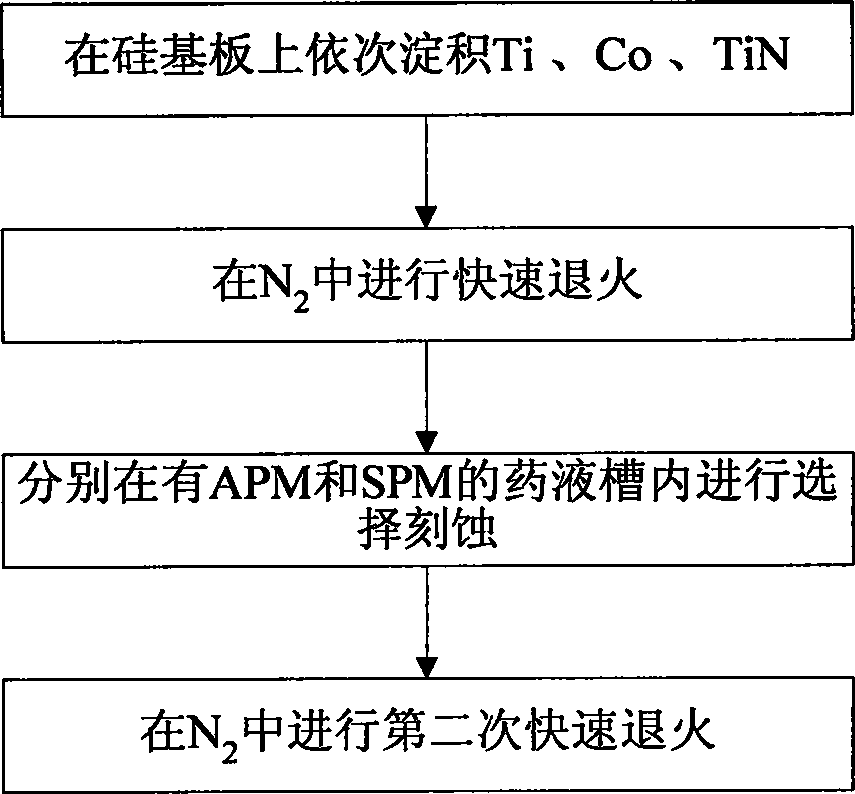

[0013] Such as figure 1 As shown, a method for preparing a cobalt silicide thin film of the present invention includes the following steps. First, Ti with a thickness of 25-45 Ȧ and a thickness of 70-150 Ȧ are respectively deposited on a silicon substrate with a 100-crystal orientation by physical vapor deposition. Co and TiN with a thickness of 80-200 Ȧ; followed by pure N at 5slm 2 The medium temperature is 580-700°C, and the process time is 60-120S for rapid annealing; again in the mixed solution of ammonium hydroxide, hydrogen peroxide and deionized water (NH 4 OH:H 2 o 2 :H 2 O=1:5:5, referred to as APM) and sulfuric acid and hydrogen peroxide mixed solution (H 2 SO 4 :H 2 o 2 =4:1, referred to as SPM) for selective etching in the chemical solution tank; finally, perform the second rapid annealing in 5slm pure N2, the temperature is 825-900°C, and the process time is 30-60S.

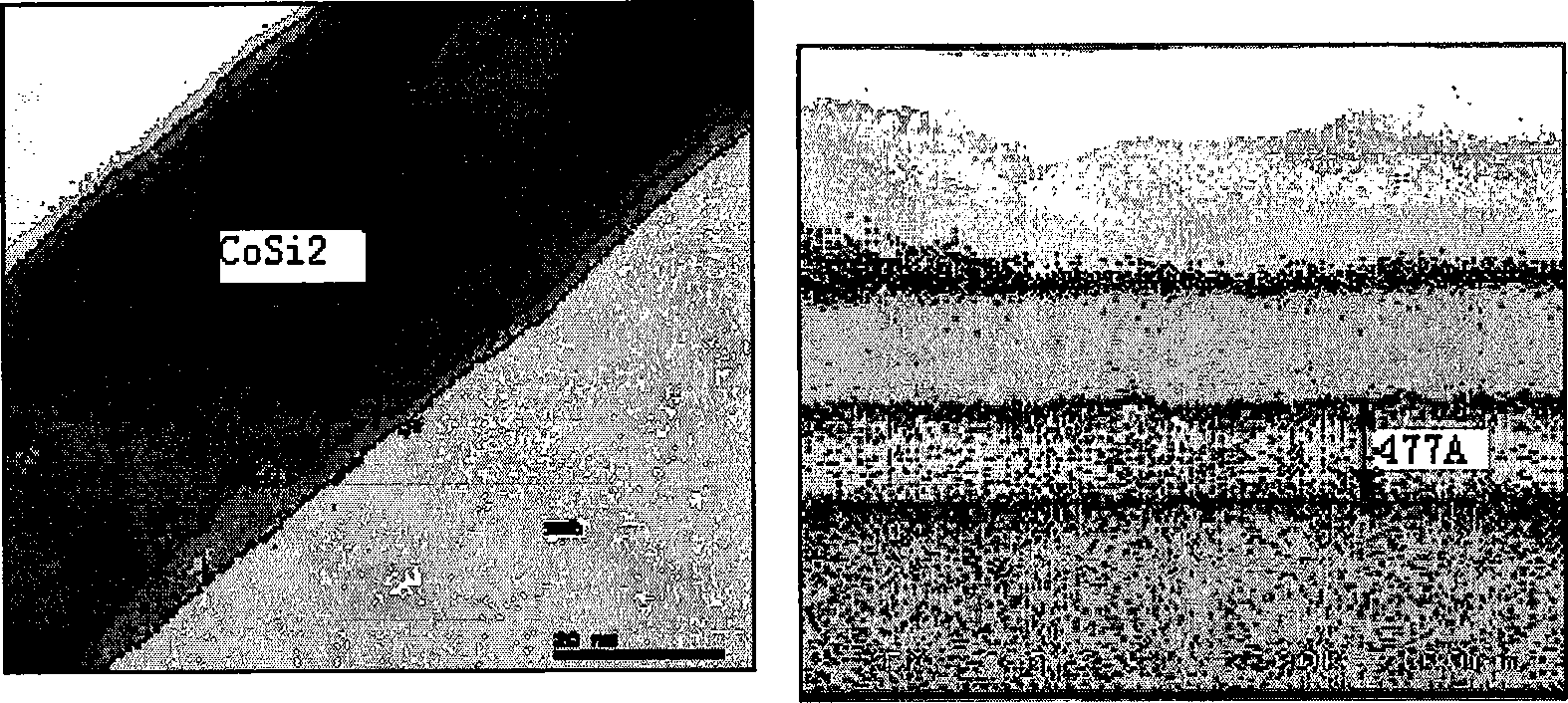

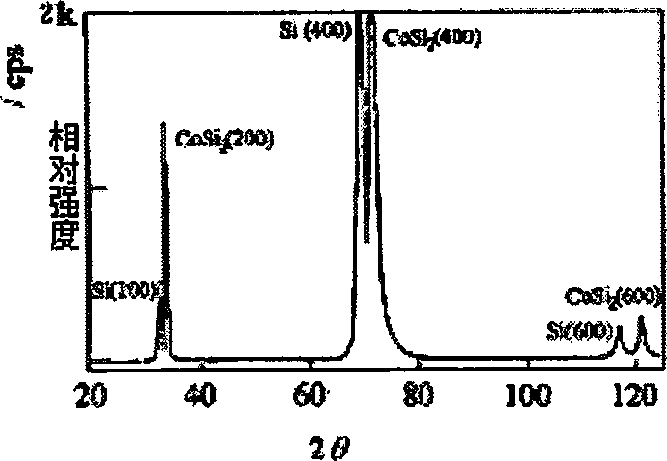

[0014] CoSi produced by a method for preparing a cobalt silicide thin film according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com