Lactide analog monomer continuous polymerization device and process

A technology of ester monomer and polymerization device, which is applied in the field of devices for continuous polymerization of lactide monomer, can solve the problems of low controllability of polymerization reaction and no control means, and achieves good controllability and power. The effect of low consumption and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The production object is polyglycolide PGA

[0039] 1. Ratio of materials: the raw material is glycolide, the initiator is stannous octoate, and the ratio of the two is: stannous octoate / glycolide=0.005% (molar ratio);

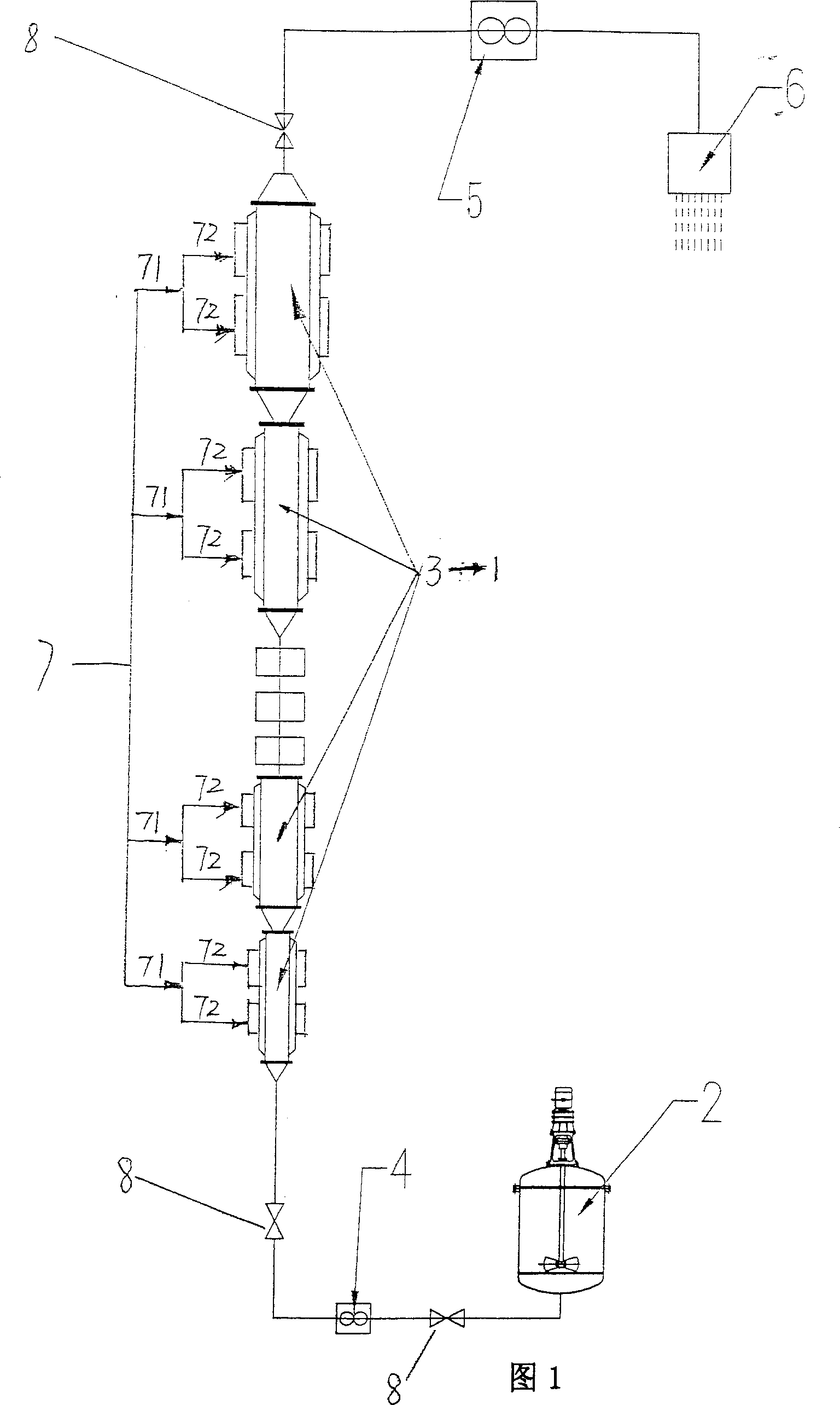

[0040]2. The process equipment includes: tubular polymerization reactor 1, melter 2, metering pump 4, gear pump 5, heating system 7:

[0041] A: Tubular polymerization reactor 1 is composed of three SK-type tubular static mixers 3 connected in series. The diameters of these three static mixers increase sequentially according to the direction of fluid flow. Their specifications and sizes are as follows:

[0042] Static mixer I has a cylinder with a diameter of 20mm, a length of 1400mm, and a built-in SK-type static mixing unit with a diameter of 20mm and a height of 20mm. It is divided into three heating zones, and the temperatures are 180°C, 190°C, and 205°C;

[0043] Static mixer II has a cylinder with a diameter of 25mm, a length of 1000mm, and a bui...

Embodiment 2

[0050] The production object is polylactide PLA

[0051] 1. Ratio of materials: the raw material is L-lactide, the initiator is stannous octoate, and the ratio of the two is: stannous octoate / L-lactide=0.01% (molar ratio);

[0052] 2. The process equipment includes: tubular polymerization reactor 1, melter 2, metering pump 4, gear pump 5, and heating system 7.

[0053] A: The tubular polymerization reactor is composed of SV and SK tubular static mixers 3 connected in series. The sequence of their serial connection is first SV and then SK type. The diameters of these four static mixers increase in sequence according to the direction of fluid flow. Large, their specifications and sizes are as follows:

[0054] Static mixer I has a cylinder with a diameter of 15mm, a length of 1200mm, and a built-in SV-type static mixing unit with a diameter of 15mm and a height of 15mm. It is divided into two heating zones, and the temperatures are 160°C and 170°C respectively;

[0055] The di...

Embodiment 3

[0063] The production object is polyisolactide PGLA (90 / 10)

[0064] 1. Material ratio: the raw material adopts glycolide / lactide=90 / 10 (molar ratio), and the initiator adopts stannous octoate, and its mol ratio with the raw material glycolide / lactide is 0.005%.

[0065] 2. The process equipment includes: tubular polymerization reactor 1, melter 2, metering pump 4, gear pump 5, heating system 7:

[0066] A: The tubular polymerization reactor is composed of two SK-type tubular static mixers 3 connected in series. The diameters of the two static mixers increase sequentially according to the direction of fluid flow. Their specifications and sizes are as follows:

[0067] Static mixer I has a cylinder with a diameter of 20mm, a length of 1600mm, a built-in diameter of 20mm, and a height of 20mm SK static mixing unit, which is divided into three heating zones, and the temperatures are 180°C, 195°C, and 215°C;

[0068] Static mixer II has a cylinder with a diameter of 25mm, a lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Barrel diameter | aaaaa | aaaaa |

| Barrel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com