Anti-bacterial additive

An antibacterial additive and antibacterial layer technology, applied in the field of antibacterial additives, can solve the problems of weakening antibacterial activity and use, and achieve the effect of lasting and stable antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of Antibacterial Melamine Formaldehyde Resin

[0062] 500 g of melamine / formaldehyde resin (Agrolinz Melamin Italia) were dissolved in 500 g of water, then 3 g of wetting agent Melpan NU02MF and 5 g of curing agent Melpan A462 (common wetting and release agent from Agrolinz Melamin Italia) were added. The precondensed mixture of aqueous amino resin was stirred until a clear solution was obtained.

[0063] Then mix into the melamine resin solution

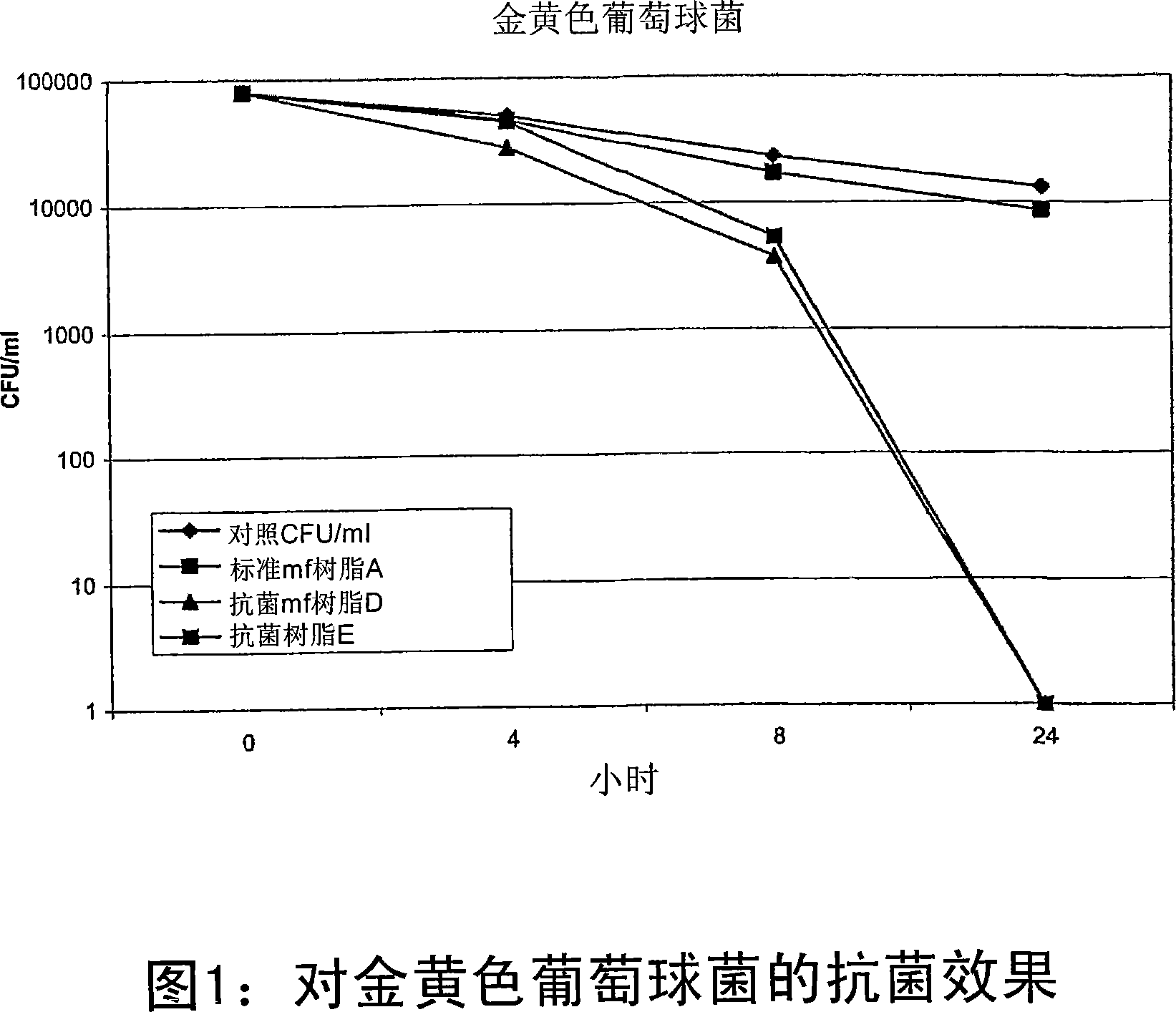

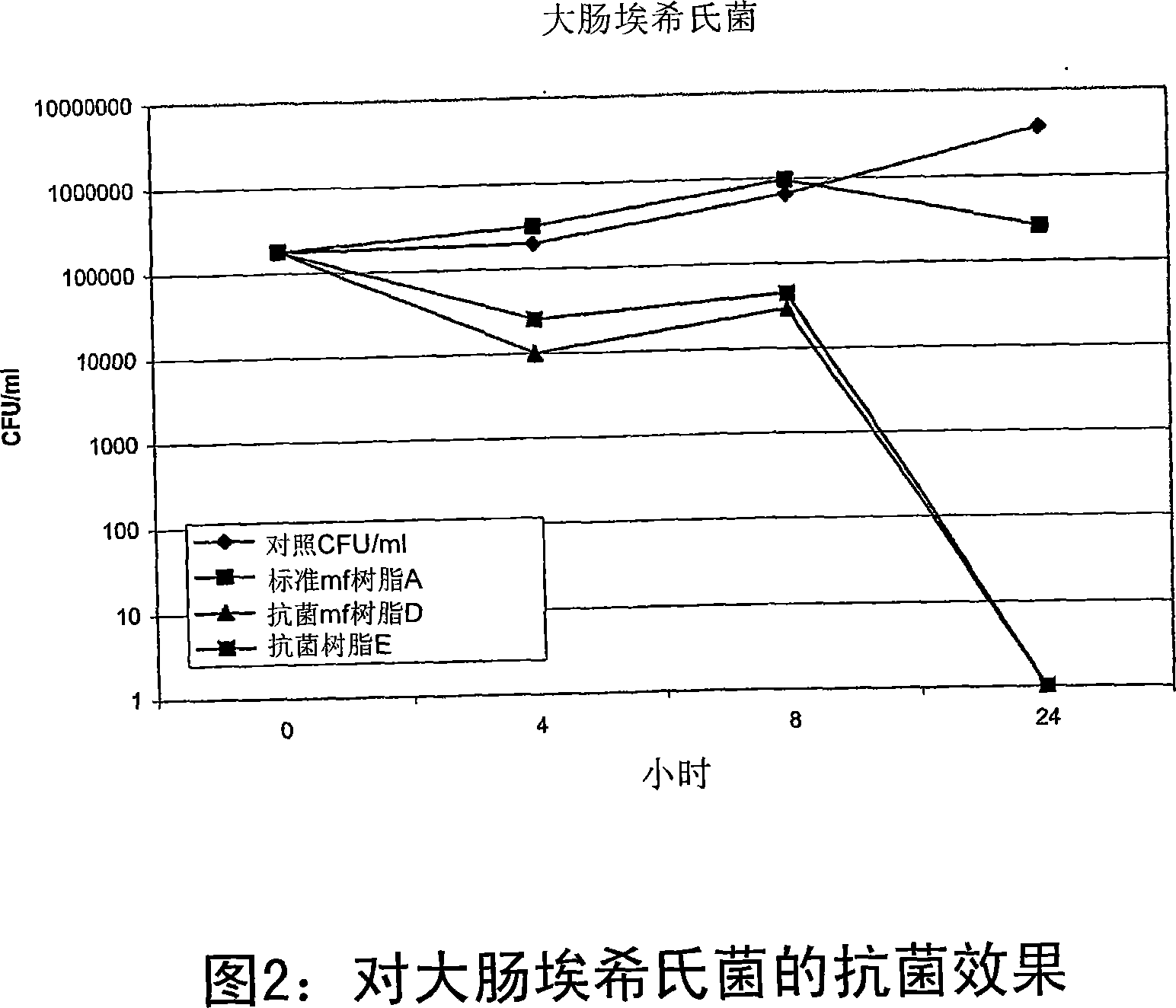

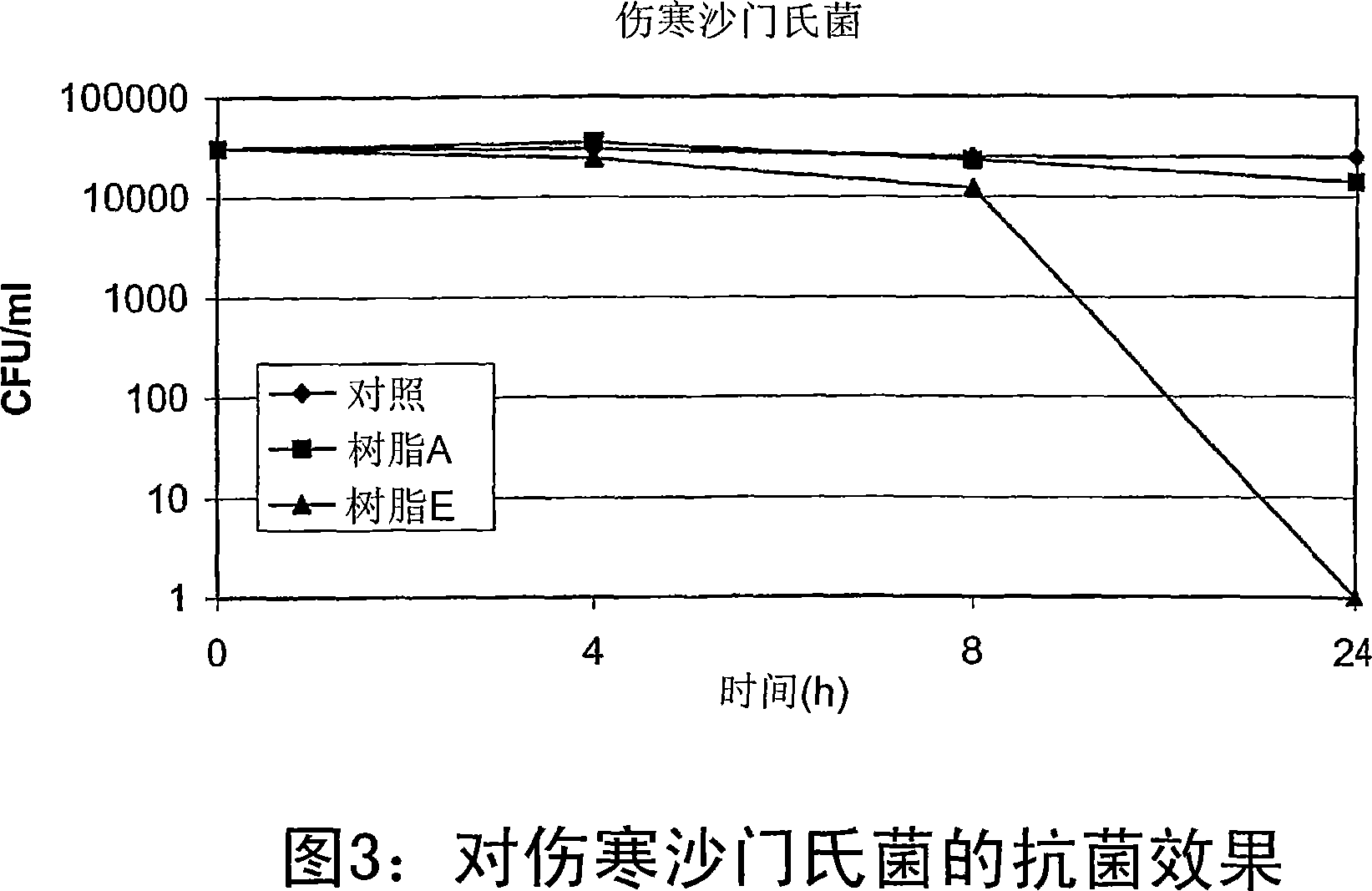

[0064] - in the case of sample D, 10 g of industrial zinc borate are mixed, and

[0065] - In the case of sample E, 2.5 g technical zinc borate, 2.5 g technical sodium borate and 1.25 g benzalkonium chloride were mixed

[0066] The solution after addition was stirred for 10 minutes until a homogeneous suspension was formed.

[0067] Production of Antimicrobial Laminates

[0068] The antibacterial melamine resin suspension is used for white decorative paper (density: 80g / m 2) for impregnation. Subsequently, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com