Ganoderma spore tablet and preparation process thereof

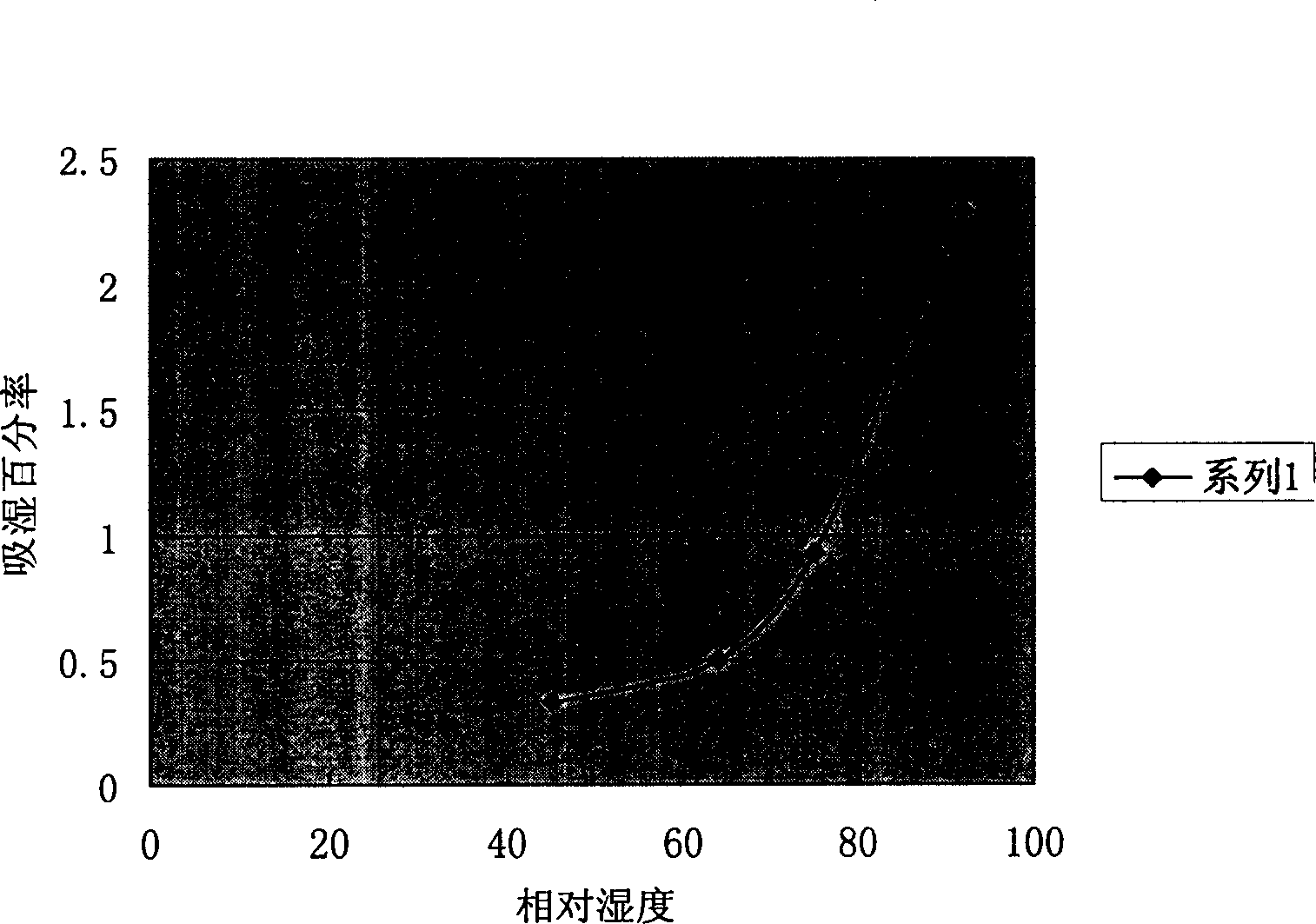

A technology of Ganoderma lucidum spore powder and spore powder tablet, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, allergic diseases, etc., and can solve problems that affect the quality of medicines, temperature, humidity, and microbial limits exceed the standard. To achieve the effect of controlling product quality, improving product quality and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

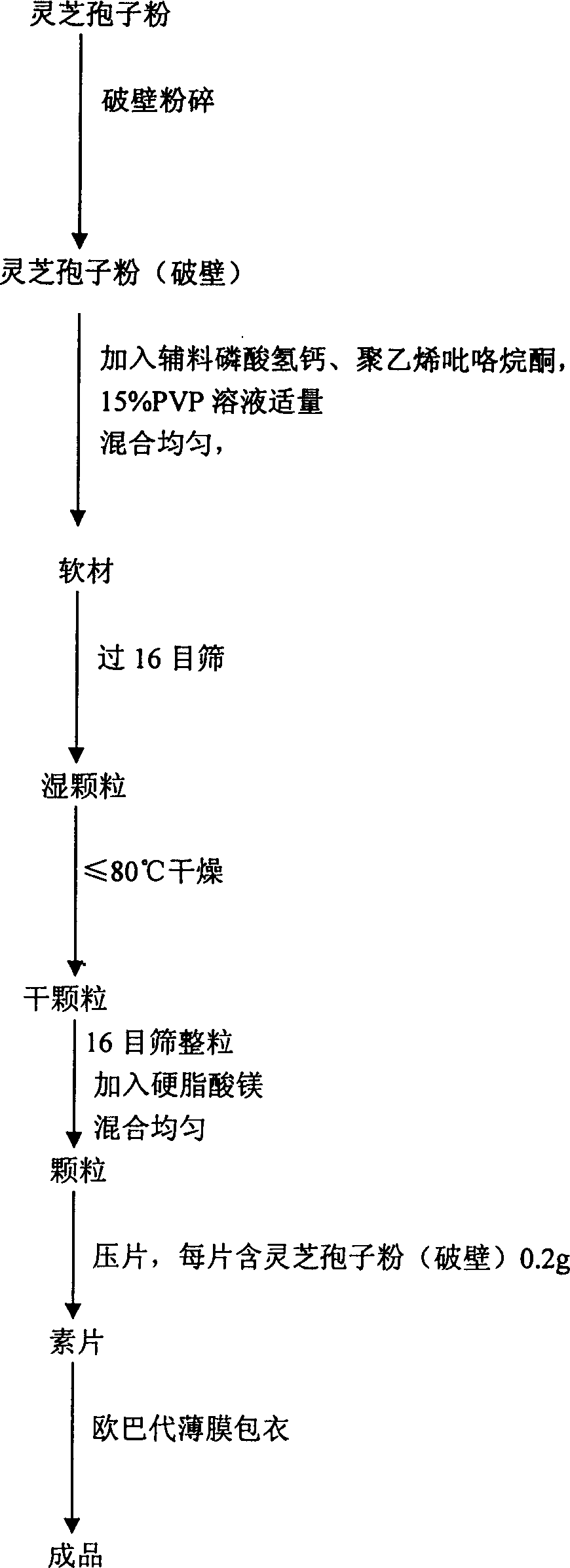

Embodiment 1

[0105] prescription:

[0106] Ganoderma lucidum spore powder 200g

[0107] Calcium hydrogen phosphate 540g

[0108] Polyvinylpyrrolidone 60g

[0110] 15% cross-linked polyvinylpyrrolidone aqueous solution 600ml

[0111] Makes 1000 pieces

[0112] Preparation process:

[0113] The ganoderma lucidum spores are taken and ultrafinely pulverized, and the wall breaking rate is greater than 85%. Take broken ganoderma lucidum spore powder, add calcium hydrogen phosphate and polyvinylpyrrolidone as auxiliary materials, mix well, use 15% cross-linked polyvinylpyrrolidone aqueous solution to make soft material, granulate with 16-mesh stainless steel sieve, dry at 70 ° C, and use 16-mesh stainless steel sieve Whole grain, add magnesium stearate and mix evenly, tabletting (as each tablet contains 0.2g of broken Ganoderma lucidum spore powder, calculate tablet weight, about 0.87g) 1000 pieces, film coating (weight gain 4%), to obtain final product.

Embodiment 2

[0115] prescription:

[0116] Ganoderma lucidum spore powder 200g

[0117] Calcium hydrogen phosphate 230g

[0118] Polyvinylpyrrolidone 20g

[0119] Magnesium Stearate 5.5g

[0120] 15% cross-linked polyvinylpyrrolidone aqueous solution 540ml

[0121] Makes 1000 pieces

[0122] Preparation process:

[0123]The ganoderma lucidum spores are taken and ultrafinely pulverized, and the wall breaking rate is greater than 85%. Take broken ganoderma lucidum spore powder, add calcium hydrogen phosphate and polyvinylpyrrolidone as auxiliary materials, mix well, use 15% cross-linked polyvinylpyrrolidone aqueous solution to make soft material, granulate with 16-mesh stainless steel sieve, dry at 80 ° C, and use 16-mesh stainless steel sieve Whole grain, add magnesium stearate and mix evenly, tabletting (as each tablet contains 0.2g of broken ganoderma lucidum spore powder, calculate tablet weight, about 0.52g) 1000 pieces, film coating (weight gain 4%), to obtain final product.

Embodiment 3

[0125] prescription:

[0126] Ganoderma lucidum spore powder 200g

[0127] Calcium hydrogen phosphate 540g

[0128] Polyvinylpyrrolidone 20g

[0129] Magnesium Stearate 8.5g

[0130] 15% cross-linked polyvinylpyrrolidone aqueous solution 540ml

[0131] Makes 1000 pieces

[0132] Preparation process:

[0133] The ganoderma lucidum spores are taken and ultrafinely pulverized, and the wall breaking rate is greater than 85%. Take broken ganoderma lucidum spore powder, add calcium hydrogen phosphate and polyvinylpyrrolidone as auxiliary materials, mix well, use 15% cross-linked polyvinylpyrrolidone aqueous solution to make a soft material, granulate with a 16-mesh stainless steel sieve, dry at 50 ° C, and use a 16-mesh stainless steel sieve Whole grain, add magnesium stearate and mix evenly, tabletting (as each tablet contains 0.2g of broken Ganoderma lucidum spore powder, calculate tablet weight, about 0.83g) 1000 pieces, film coating (weight gain 4%), to obtain final produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com