Method for preparing pseudo-boehmite with large pore volume and high specific surface area

A technology of pseudo-boehmite and high specific surface, which is applied in the direction of alumina/aluminum hydroxide to achieve the effect of shortening the process flow, large pore volume and high specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

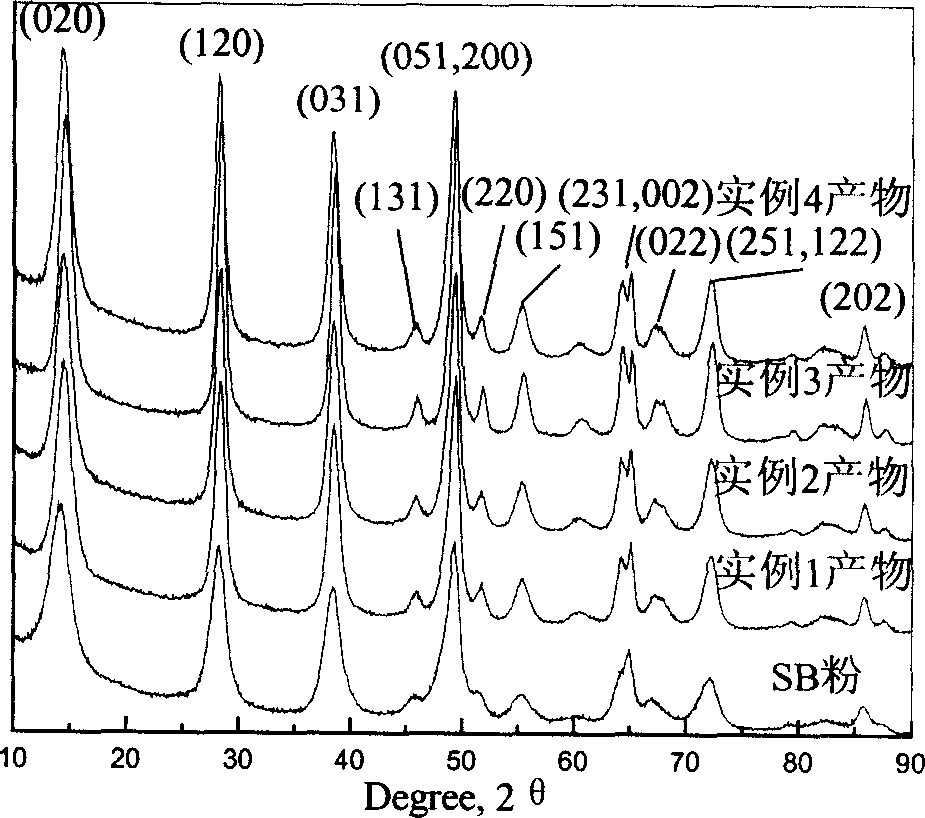

[0030] Embodiment 1: A certain amount of SB powder is added to the compound containing 140g / L-Al 2 o 3 , causticization coefficient α K In the 40ml sodium aluminate solution of 1.30, the addition amount of SB powder is the same as that of Al in the sodium aluminate solution 2 o 3 The weight ratio is 1:1, continuous hydrothermal decomposition at 125°C for 3 hours, and the decomposition rate is 31.7%; the decomposition product is cooled, vacuum filtered, and washed with deionized water to neutrality, and dispersed with ethanol twice the volume of the solid And washing, after the filter cake was dried at 100°C for 12 hours, the dried product was detected by XRD as 100% pseudo-boehmite, and its specific surface area and pore volume measured by a fully automatic specific surface and porosity analyzer were 176.8 m 2 / g and 0.59cm 3 / g.

Embodiment 2

[0031] Embodiment 2: A certain amount of SB powder is added to the compound containing 110g / L-Al 2 o 3 , causticization coefficient α K In 40ml sodium aluminate solution of 1.75, the addition amount of SB powder is the same as that of Al in sodium aluminate solution 2 o 3 The weight ratio is 1:1, continuous hydrothermal decomposition at 100°C for 16 hours, and the decomposition rate is 16.2%; the decomposition product is cooled, vacuum filtered, and washed with deionized water to neutrality, and dispersed with ethanol 4 times the volume of the solid And washed, after the filter cake was dried at 120°C for 10 hours, the dried product was detected by XRD as 100% pseudo-boehmite, and its specific surface and pore volume measured by a fully automatic specific surface and porosity analyzer were 195.2 m 2 / g and 0.86cm 3 / g.

Embodiment 3

[0032] Embodiment 3: A certain amount of SB powder is added to the powder containing 200g / L-Al 2 o 3 , causticization coefficient α K In the 40ml sodium aluminate solution of 1.30, the addition amount of SB powder is the same as that of Al in the sodium aluminate solution 2 o 3 The weight ratio is 1:1, continuous hydrothermal decomposition at 150°C for 9 hours, and the decomposition rate is 23.1%; the decomposition product is cooled, vacuum filtered, and washed with deionized water to neutrality, and then dispersed with ethanol twice the volume of the solid And washed, after the filter cake was dried at 110°C for 11 hours, the dried product was detected by XRD as 100% pseudo-boehmite, and its specific surface and pore volume measured by a fully automatic specific surface and porosity analyzer were 181.3 m 2 / g and 0.78cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com