Ferment method for producing 2.3-butanediol

A butanediol, fermentation and cultivation technology, applied in the 2 field, can solve the problems of low conversion rate, long fermentation cycle, low yield of 2,3-butanediol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

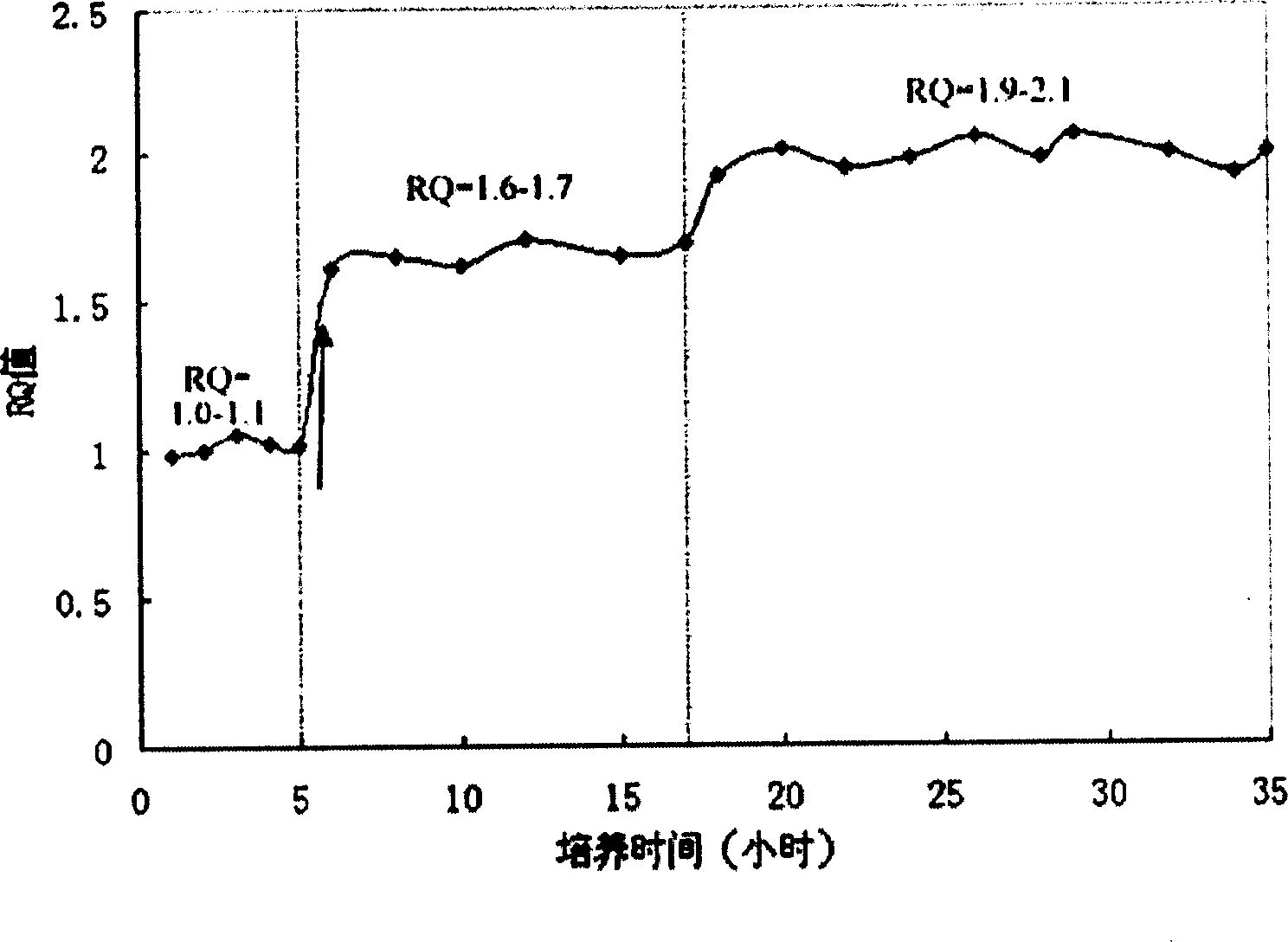

Image

Examples

Embodiment 1

[0050] The following are percentages by weight.

[0051] Yeast powder 0.5%, peptone 2%, citric acid 1%, MnSO 4 0.007%, KH 2 PO 4 0.05%, MgSO 4 0.05% add 800ml water to dissolve;

[0052] Weigh FeSO 4 ·7H 2 O 0.002%, add 20ml of water to dissolve, add 3ml of hydrochloric acid with a concentration of 1 / 4 (v / v) to help dissolve, make the solution clearer, and filter with a sterile filter membrane;

[0053] Mix the above medium, adjust to 7.20 with 5mol / l NaOH solution, add water to 1L, and sterilize;

[0054] The sterilized sucrose is mixed with the above-mentioned cooled medium to obtain 9% sucrose, namely to obtain the fermentation medium.

Embodiment 2

[0056] (1) Seed culture of Serratia marcescens:

[0057] The culture time is 12 hours, and the culture temperature is 28 DEG C. The components and weight content of the culture medium are: glucose 1%; yeast powder 0.1%; peptone 0.2%; (NH 4 ) 2 SO 4 0.6%;K 2 HPO 4 1%; NaCl 0.05%; MgSO 4 0.05%; adjust pH 7.2 with NaOH.

[0058] (2) Fermentation culture:

[0059] The volume of the initial fermentation medium is 1.8L, and the composition of the initial medium used is as follows

[0060] Sucrose 9%

[0061] Peptone 2%

[0063] Citric acid 1%

[0064] MnSO 4 0.007%

[0065] NaH 2 PO 4 0.05%

[0066] FeSO 4 0.002%

[0067] MgSO 4 0.05%

[0068] The concentration of each component of the feeding solution is:

[0069] Feed 1 sucrose aqueous solution: 500g / 600ml;

[0070] Feed 2 Industrial amino acid powder aqueous solution: 40g / 200ml; (added in the second stage)

[0071] Inoculate the Serrat...

Embodiment 3

[0077] Production of 2,3-butanediol by Serratia marcescens using the original medium.

[0078] Medium composition:

[0079] Glucose 5%, maltose extract 0.3%, yeast powder 0.3%, peptone 0.5%, and the pH was adjusted to 7.2 before sterilization.

[0080] Insert the Serratia marcescens seed liquid with the inoculum size of 5% (volume ratio), 30 ℃ shaker, 200rpm cultivate, with NaOH and H 2 SO 4 The pH of the cultivation process was controlled to be 6.0. After 42 hours, the sugar was consumed, and the 2,3-butanediol production was measured to be 15 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com