High molecular plastic alloy powder for hot molten thick lining

A technology of plastic alloy and polymer, applied in the field of composite powder for polymer plastic alloy hot-melt thick film lining, can solve the problems of poor anti-corrosion performance, short service life, polluting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation manner of the present invention will be described in detail below in combination with the actual situation.

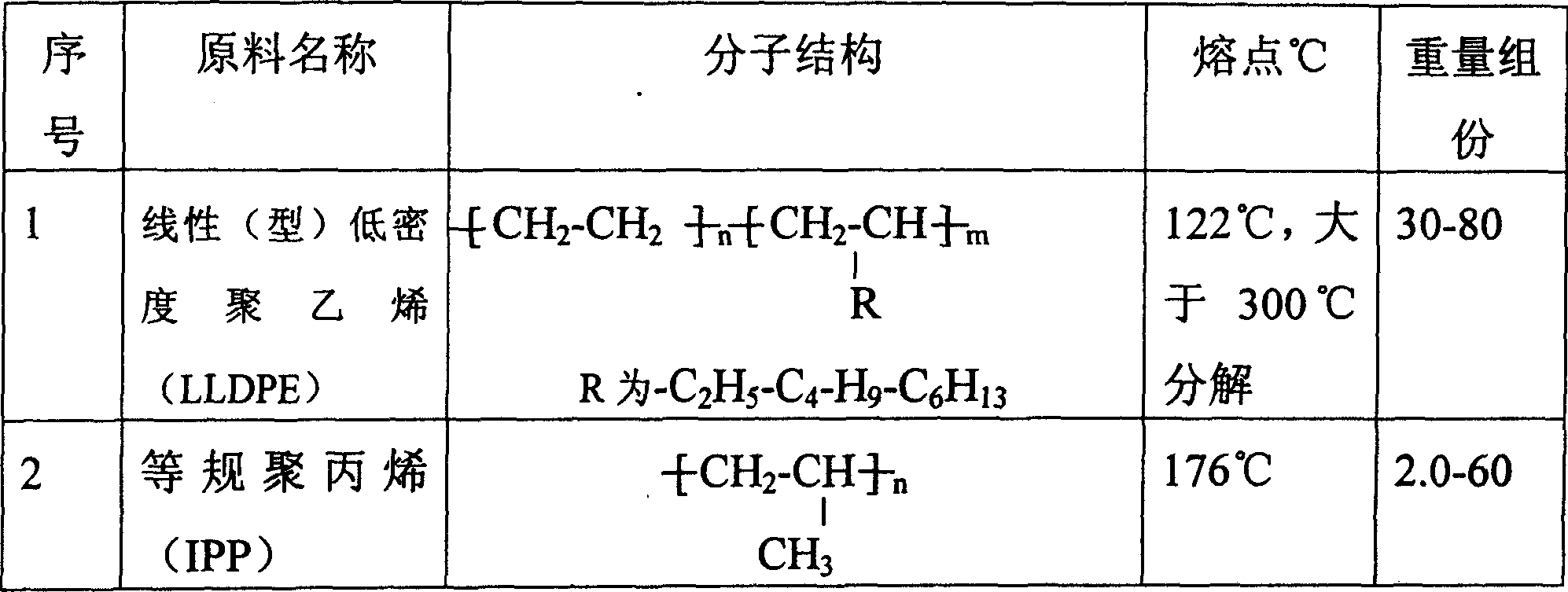

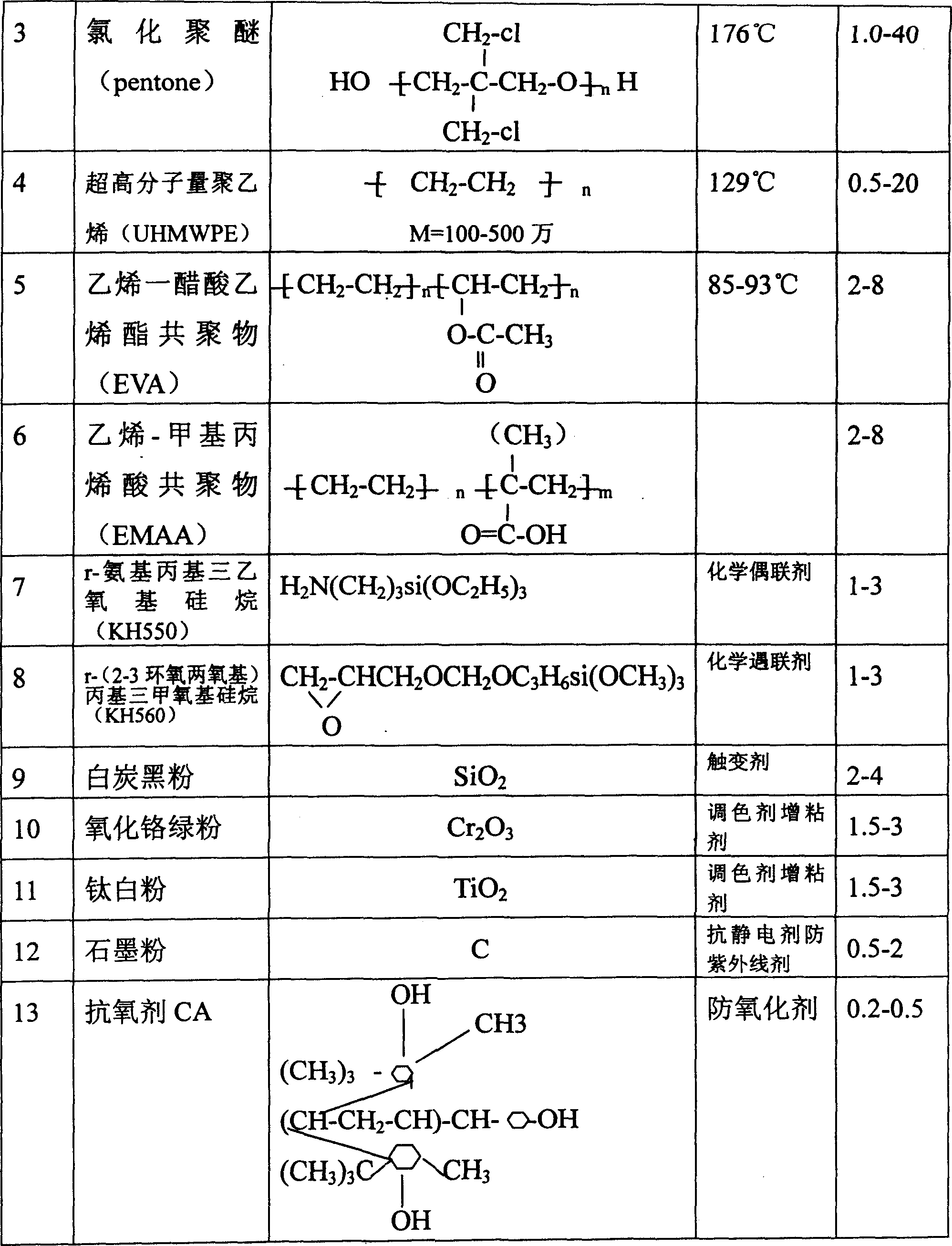

[0008] Given by the technical proposal, the present invention is by weight: 30-80 parts of linear low density polyethylene, 2-60 parts of isotactic polypropylene, 1-40 parts of chlorinated polyether, 0.5- 20 parts, 2-8 parts of ethylene-vinyl acetate copolymer, 2-8 parts of ethylene-methacrylic acid copolymer, 1-3 parts of r-aminopropyltriethoxysilane, r-(2-3 epoxy Dioxy)propyltrimethoxysilane 1-3 parts, white carbon black powder 2-4 parts, chromium oxide green powder 1.5-3 parts, titanium dioxide 1.5-3 parts, graphite powder 0.5-2 parts and antioxidant Composition of 0.2-0.5 parts of CA.

[0009] The details of each component are shown in the table below:

[0010]

[0011]

[0012] 1. In specific implementation, the present invention can adopt by weight: 60 parts of linear low density polyethylene, 13 parts of isotactic polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com