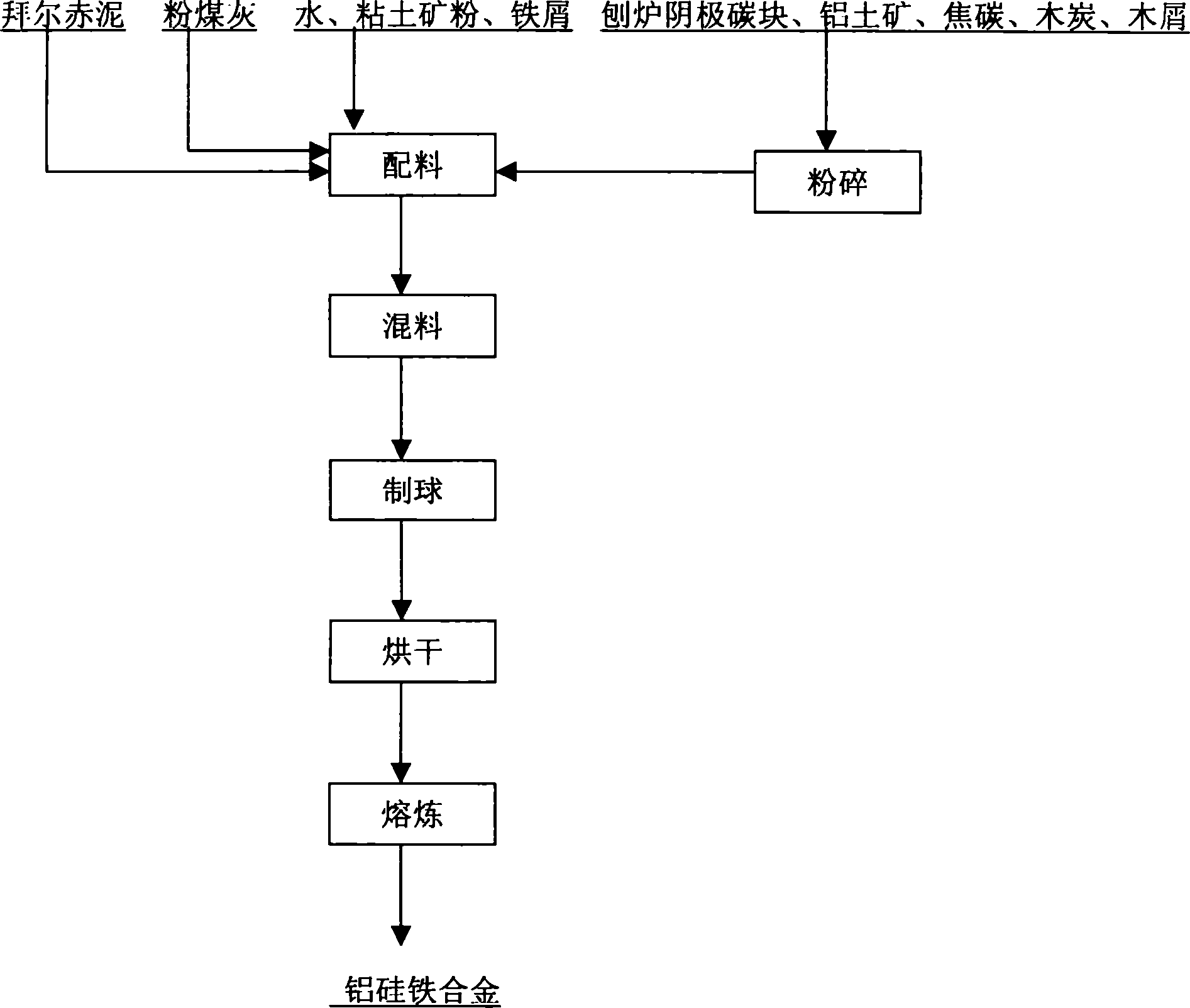

Direct Al-Si-Fe alloy smelting process in ore smelting furnace

A production method and submerged arc furnace technology, applied in the field of aluminum alloy smelting and production, can solve the problems of difficult waste stacking, heavy pollution, land occupation, etc., and achieve the effects of low production cost, improved environment, and increased resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the invention:

[0017] According to the needs of users, the main components of alloy products to be smelted are: Al 37-40%, Si 25-30%, Fe 20-25%, and other 10%.

[0018] The main components of the raw materials used are:

[0019] 1. Bayer Red Mud Al 2 o 3 27%, SiO 2 16%, Fe 2 o 3 8.33%.

[0020] 2. Fly ash Al 2 o 3 18%, SiO 2 45%, Fe 2 o 3 7%.

[0021] 3. Planer cathode carbon block Al 2 o 3 4.551%, SiO 2 0.784%, C 66.591%.

[0022] 4. The aluminum-silicon ratio of clay ore is 1.1.

[0023] 5. The aluminum-silicon ratio of bauxite is 8.

[0024] Calculate the main raw material formula required: Bayer red mud 25%, fly ash 10%, clay ore 12%, bauxite 8%, iron filings 10%, planer cathode carbon block 22%, coke 5%, Charcoal 5%, wood chips 3%.

[0025] Then follow these steps:

[0026] 1. After the Bayer red mud, fly ash, clay ore, bauxite and planer cathode carbon block and coke are roughly crushed and finely crushed, weigh accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com