Method for realizing brazing in metal straight pipe, and its special apparatus

A special equipment and brazing technology, which is applied in the field of brazing in metal straight pipes by means of high-frequency induction heating, can solve problems such as poor heat dissipation performance of radiators, inability to compound aluminum alloy fins, and difficulties in argon arc welding processes. Achieve the effects of reducing manual operation and labor, reliable performance, and reducing welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

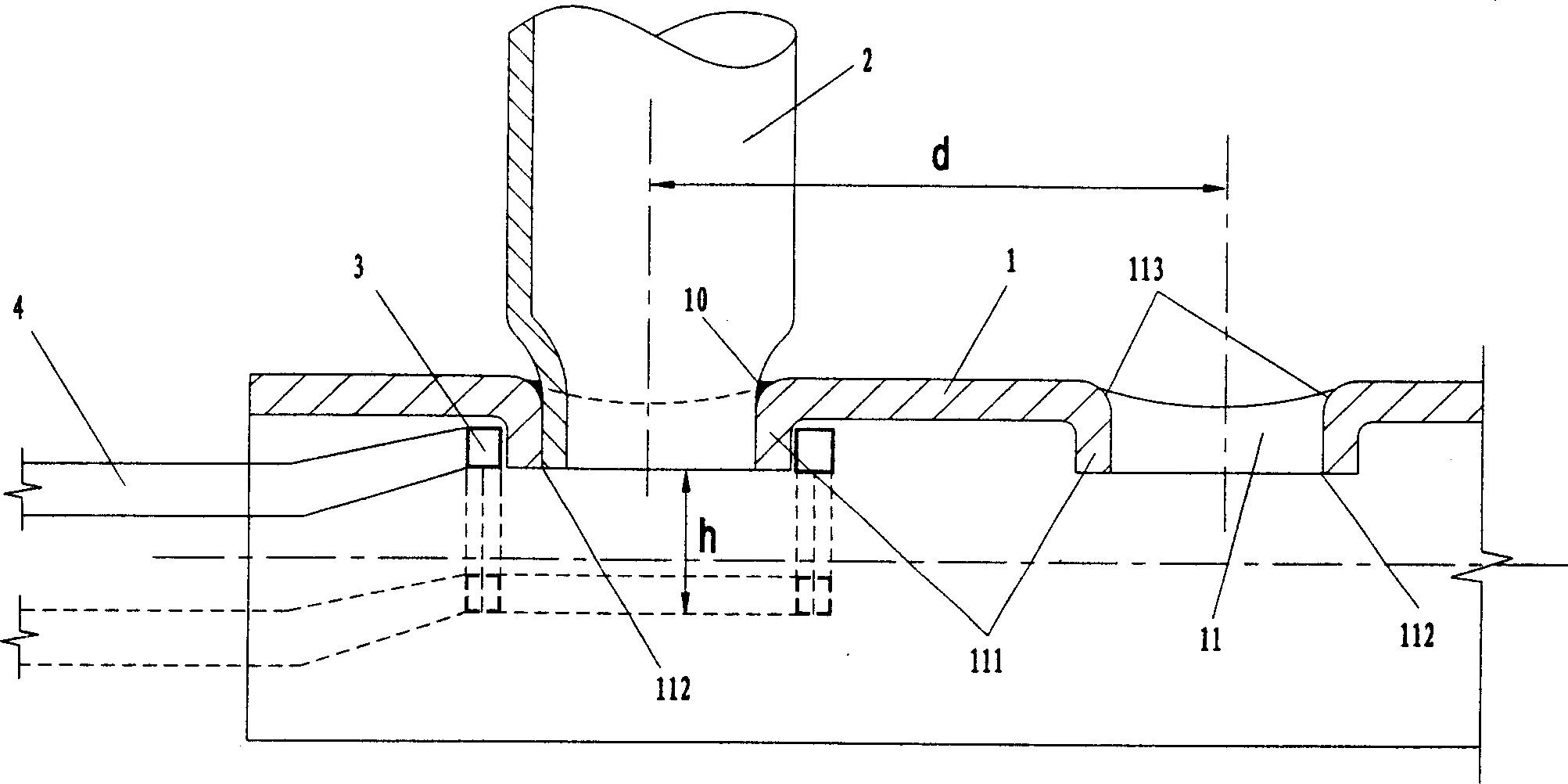

[0035] Taking the welding of the main flow pipe and the shunt pipe of the heating radiator and the solar collector plate as an example, further details will be given in conjunction with the accompanying drawings.

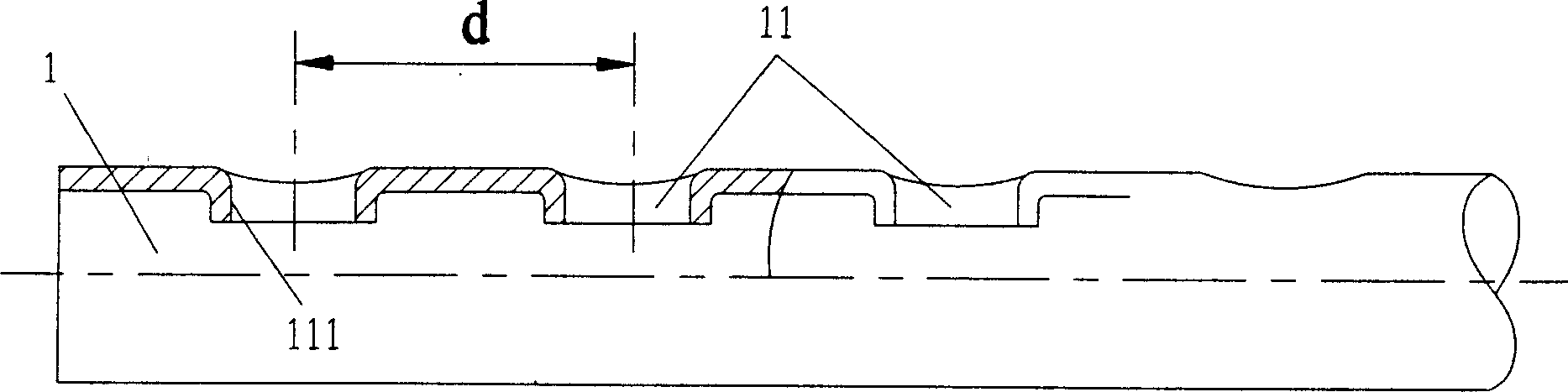

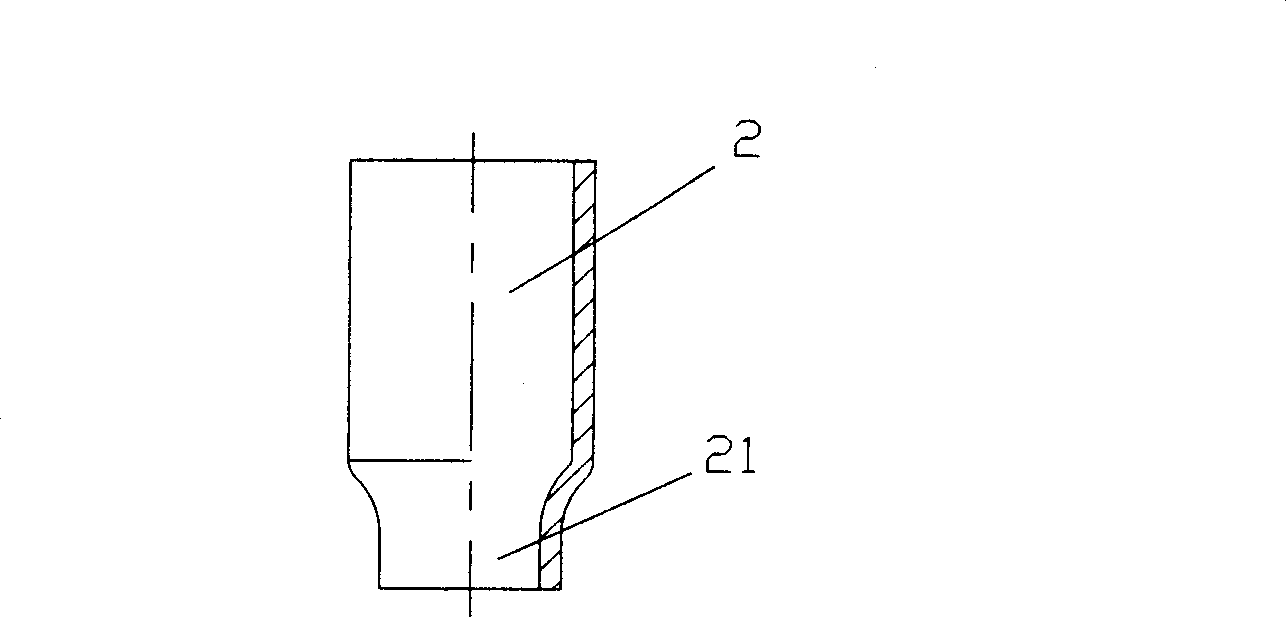

[0036] Such as Figure 7 and Figure 8 As shown, the heating radiator welded by the brazing method and special equipment of the present invention is mainly composed of two main flow pipes 1 parallel to the upper and lower sides, and a plurality of main flow pipes 1 connected between the two main flow pipes 1 to make it penetrate. The shunt tube 2 and the cooling fins 9 covering the outer surface of the shunt tube 2 are composed. The main flow pipe 1 and the branch pipe 2 are all made of stainless steel with high strength and good corrosion resistance, wherein the main flow pipe 1 can be a square pipe or a semi-square and semi-circular pipe with at least one side being flat. In this embodiment, 30 × 30, 40 × 40, 50 × 50 or 60 × 60 (mm) or more square pipes, the shu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com