High efficient biological purifying process and system for organic waste gas

A technology for organic waste gas and biological purification, which is applied in air quality improvement, chemical instruments and methods, and dispersed particle separation, etc. It can solve the problems of speed limitation of biodegradation, limitation of the speed of biodegradation, and difficulty in opening benzene ring chains. , to achieve the effect of mild treatment conditions, long service life and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with reality and accompanying drawing.

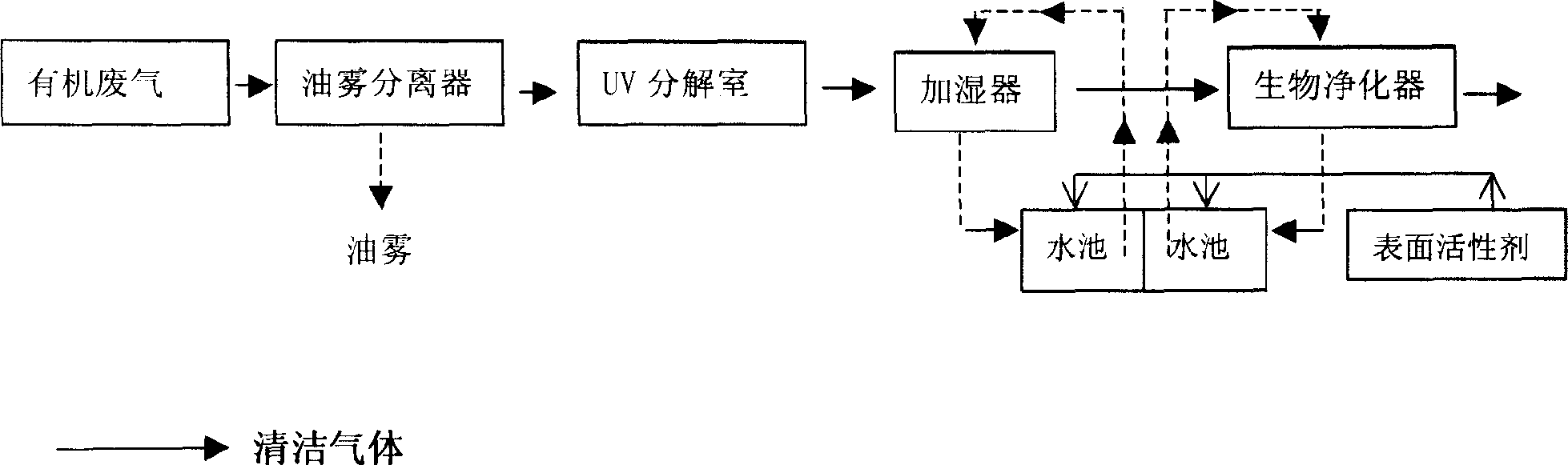

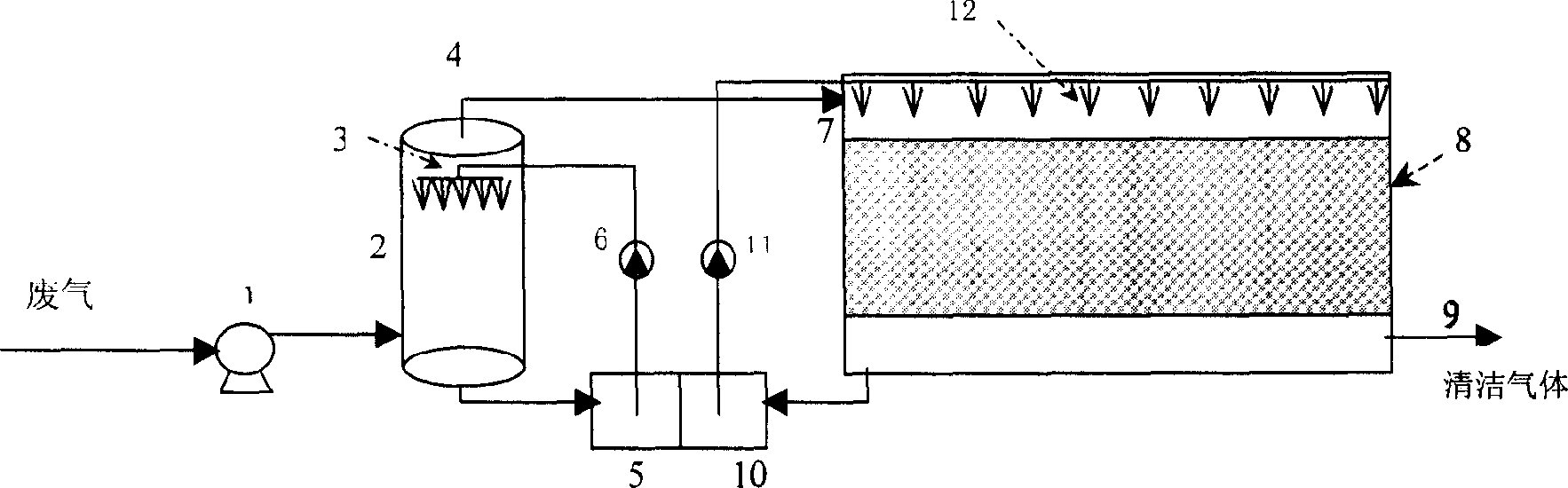

[0030] like figure 1 The high-efficiency biological purification system for organic waste gas of the present invention includes four parts, an oil mist separator, a UV decomposition chamber, a biological purifier, a water circulation humidification system and a surfactant adding system.

[0031] The organic waste gas enters the first-stage oil mist separator to separate the oil mist, and then decomposes through ultraviolet light to decompose the biodegradable benzene ring substances into small molecules or crack the benzene ring substances through UV. Thereby greatly improving the biodegradability of benzene ring substances. The substances decomposed by UV are then bio-degraded through biological filtration. Since organic solvents and benzene-ring organic substances are mostly hydrophobic substances that are difficult to dissolve in water, surfactants are adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com