Liquid crystal tropism agent and liquid crystal display element

A technology of liquid crystal display elements and liquid crystal alignment agents, which is applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of easy repulsion, decline in electrical characteristics of liquid crystal display elements, easy generation of pores, etc., and achieve excellent voltage retention rate , excellent orientation and reliability, and good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

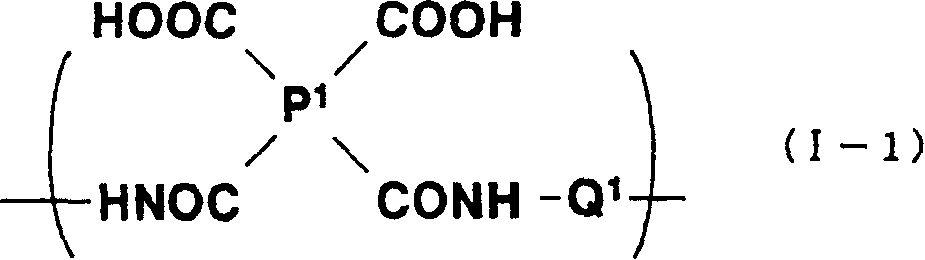

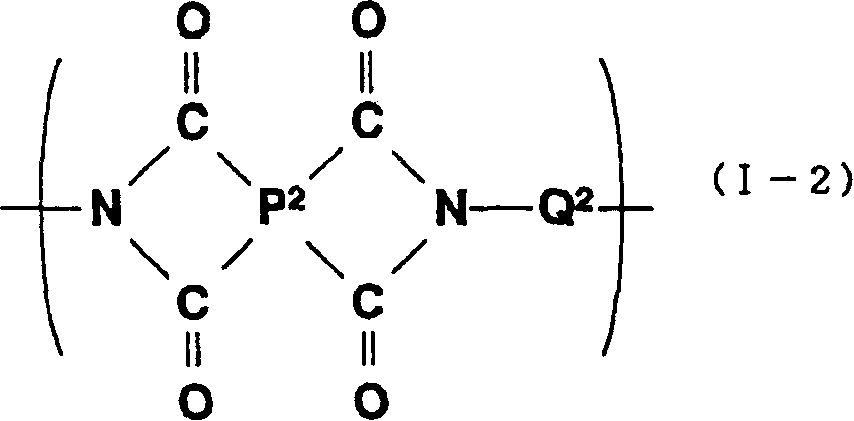

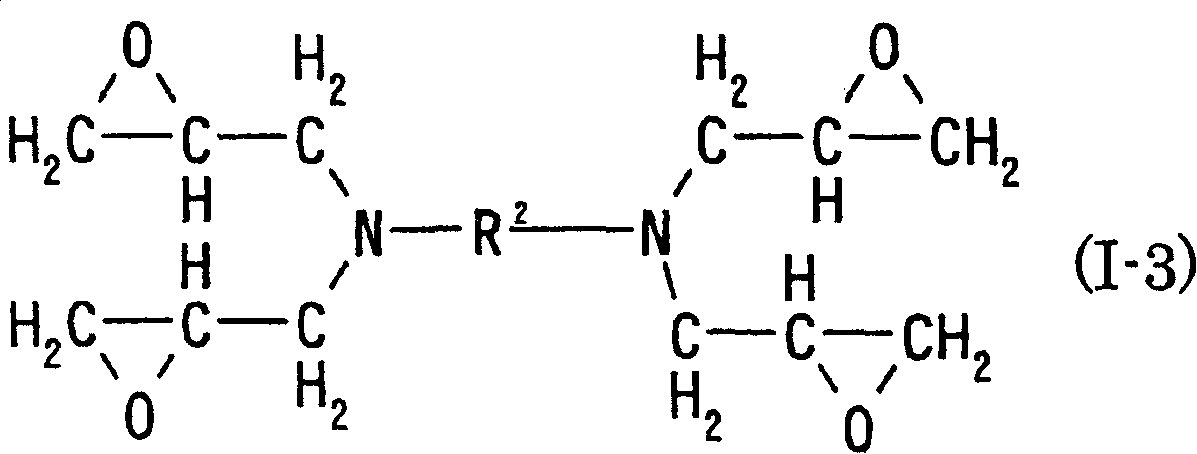

Method used

Image

Examples

Synthetic example 1

[0103] 224.17g (1.0 mole) of 2,3,5-tricarboxycyclopentyl acetic acid dianhydride as tetracarboxylic acid dianhydride and 108.14g (1.0 mole) of p-phenylenediamine as diamine compound are dissolved in 4500g N- Methyl-2-pyrrolidone was reacted at 60°C for 6 hours. Next, the reaction solution was poured into a large excess of methanol to precipitate the reaction product. Then, washing|cleaning with methanol and drying at 40 degreeC under reduced pressure for 15 hours obtained 380 g of polyamic acids whose logarithmic viscosity was 0.75 dl / g. 30 g of the obtained polyamic acid was dissolved in 570 g of N-methyl-2-pyrrolidone, 23.4 g of pyridine and 18.1 g of acetic anhydride were added, and dehydration and ring closure were carried out at 110° C. for 4 hours. Precipitation, washing, and reduction were performed in the same manner as above. was pressed to obtain 18.2 g of a polyimide having a logarithmic viscosity of 0.68 dl / g (this was referred to as "polyimide (A-1)").

Synthetic example 2

[0105] In Synthesis Example 1, except that 198.27 g (1.0 mol) of 4,4'-diaminodiphenylmethane was used as the diamine compound, 390 g of a compound having a logarithmic viscosity of 0.55 dl / g was obtained in the same manner as in Synthesis Example 1. polyamic acid. 30 g of the obtained polyamic acid was dissolved in 570 g of N-methyl-2-pyrrolidone, 5.7 g of pyridine and 7.4 g of acetic anhydride were added, and dehydration and ring closure were carried out at 110° C. for 4 hours. Precipitation, washing, and reduction were carried out in the same manner as above. was pressed to obtain 20.5 g of a polyimide having a logarithmic viscosity of 0.49 dl / g (this was referred to as "polyimide (A-2)").

Synthetic example 3

[0107]In Synthesis Example 1, except that 200.24 g (1.0 mol) of 4,4'-diaminodiphenyl ether was used as the diamine compound, 390 g of 4,4'-diaminodiphenyl ether with a logarithmic viscosity of 0.52 dl / g was obtained in the same manner as in Synthesis Example 1. polyamic acid. 30 g of the obtained polyamic acid was dissolved in 570 g of N-methyl-2-pyrrolidone, 5.7 g of pyridine and 7.4 g of acetic anhydride were added, and dehydration and ring closure were carried out at 110° C. for 4 hours. Precipitation, washing, and reduction were carried out in the same manner as above. was pressed to obtain 18.5 g of a polyimide having a logarithmic viscosity of 0.48 dl / g (this was referred to as "polyimide (A-3)").

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com