Bamboo louver sheet and its making method

The technology of a shutter sheet and a manufacturing method, which is applied in the field of building materials processing, can solve the problems of short service life, waste of resources, complicated processes, etc., and achieve the effects of reducing production costs, reducing waste of raw materials, and expanding the scope of material selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

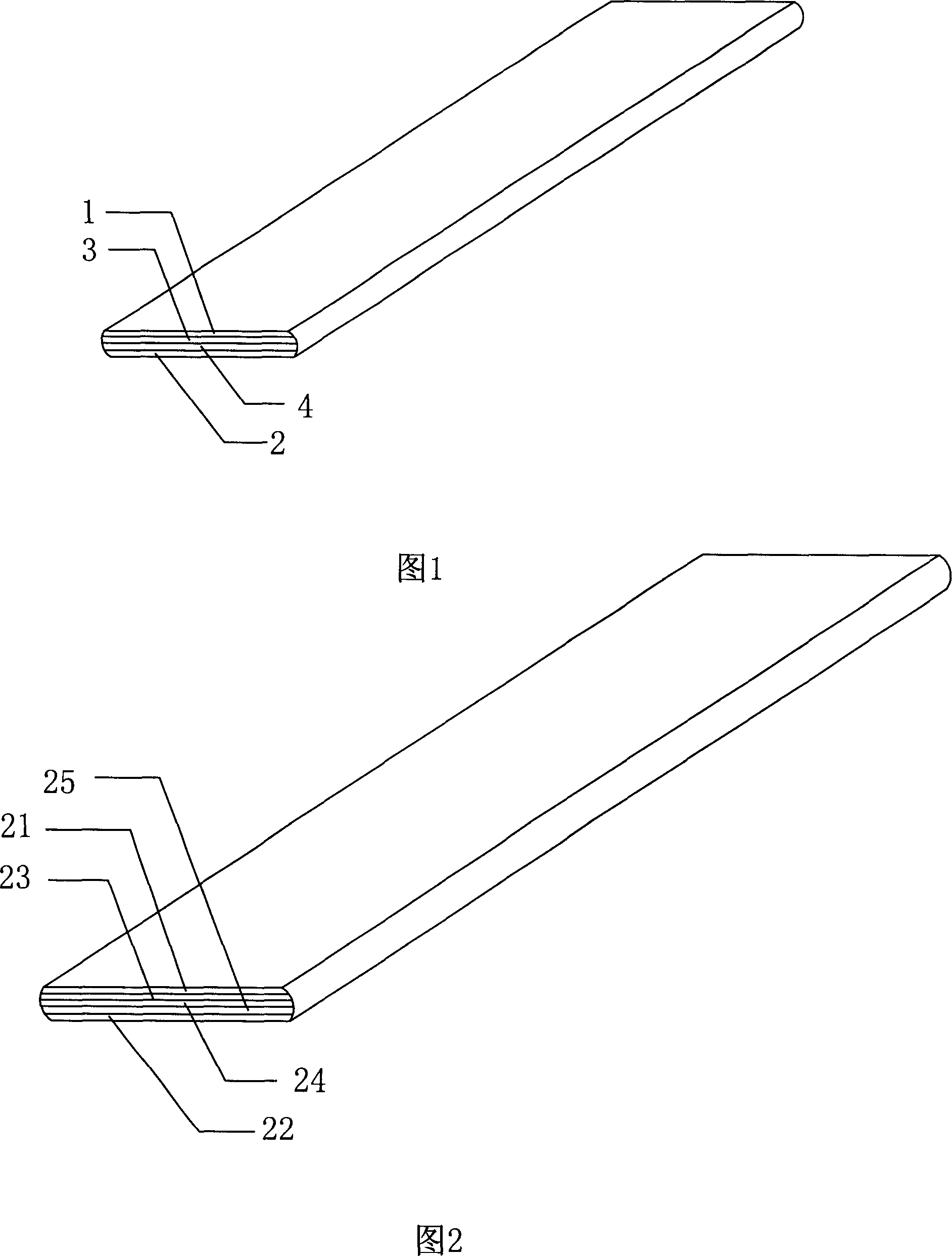

[0022] A kind of bamboo louver, comprising rotary-cut bamboo veneer, described rotary-cut bamboo veneer has two layers, there are two layers of filling layers 3,4 between two layers of rotary-cut bamboo veneer 1,2, described The filling layers 3 and 4 are made of wood boards, and the rotary-cut bamboo veneers 1 and 2 and the wood boards are formed into a whole by laminating and hot-pressing in the thickness direction.

[0023] The method for manufacturing bamboo blinds comprises the following steps:

[0024] (1) select the bamboo material after anti-insect, anti-mildew, anti-corrosion treatment, intercept certain length, be processed into the rotary-cut bamboo veneer 1,2 of 0.5mm through the bamboo veneer rotary-cutting machine;

[0025] (2) select the wood after the insect-proof, mildew-proof and anti-corrosion treatment, cut a certain length, and process it into a 0.5mm plank layer through a planer;

[0026] (3) Dry the rotary-cut bamboo veneer and veneer, and after the dry...

specific Embodiment 2

[0029] A bamboo louver, comprising rotary-cut bamboo veneer, said rotary-cut bamboo veneer has two layers, and there are three layers of filling layers 23, 24, 25 between the two layers of rotary-cut bamboo veneer 21, 22, said The filling layer adopts the wood board layer, and the described rotary-cut bamboo veneers 21, 22 and the wood board layer are formed into a whole by laminating and hot-pressing in the thickness direction.

[0030] The method for manufacturing bamboo blinds comprises the following steps:

[0031] (1) select the bamboo material after anti-insect, anti-mildew, anti-corrosion treatment, intercept certain length, be processed into the rotary-cut bamboo veneer 21,22 of 0.5mm through the bamboo veneer rotary-cutting machine;

[0032] (2) select the wood after the insect-proof, mildew-proof and anti-corrosion treatment, cut a certain length, and process it into a 0.5mm plank layer through a planer;

[0033] (3) Dry the rotary-cut bamboo veneer and veneer, afte...

specific Embodiment 3

[0036] A bamboo louver, comprising a rotary-cut bamboo veneer, the rotary-cut bamboo veneer has two layers, the inner side of the rotary-cut bamboo veneer is also lined with non-woven fabric, and the two layers are lined with non-woven fabric There are two layers of filling layers between the rotary-cut bamboo veneers of the cloth, and the described filling layer adopts the wood layer, and the described two layers of the rotary-cut bamboo veneer and the wood layer lined with non-woven fabric are laminated in the thickness direction. Pressing, hot pressing and gluing to form a whole.

[0037] The method for manufacturing the bamboo louver is the same as in Example 1 except that the inner side of the two-layer rotary-cut bamboo veneer is lined with non-woven fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com