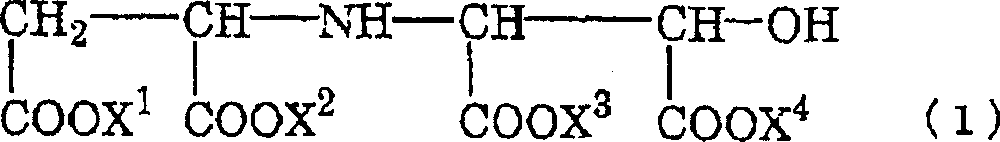

Iminocarboxylic acid salt-containing solid composition and production method thereof

An iminocarboxylate, solid composition technology, applied in the directions of organic cleaning compositions, inorganic/elementary cleaning compositions, chemical instruments and methods, etc., can solve problems such as no disclosure or indication of solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

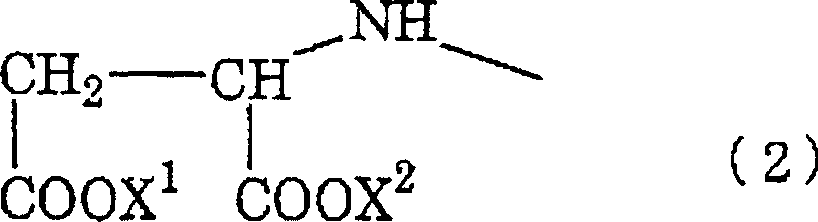

[0056] 1761g epoxy succinic acid disodium salt, 1770g L-aspartic acid disodium salt and 3100g water were mixed and reacted at 90°C for 4 hours to obtain 50 mass of 3-hydroxyimine disuccinic acid tetrasodium salt (HIDS4Na) % aqueous solution. A 50% by mass aqueous solution of HIDS4Na was dried using a spray dryer (manufactured by Fujisaki Electric Co., Ltd.) to obtain a powder containing L-HIDS4Na in which the aspartic acid skeleton part represented by the aforementioned general formula (2) was L type. During the drying process, no sticky matter was found on the wall surface of the device, pipes, etc.

[0057] The content of L-HIDS4Na contained in the obtained powder was analyzed by high-speed liquid chromatography and found to be 81% by mass. Furthermore, the water content was analyzed by a differential thermal analysis device and found to be 10% by mass.

Synthetic example 2

[0059] Replace L-aspartic acid disodium salt with D-aspartic acid disodium salt, and others are reacted and dried the same as Synthetic Example 1 to obtain a powder comprising D-HIDS Na. In D-HIDS Na, the aforementioned general formula (2 ) represents the aspartic acid skeleton part is D-type.

[0060] The content of D-HIDS4Na contained in the obtained powder was analyzed by high-speed liquid chromatography and found to be 80% by mass. Furthermore, the water content was analyzed by a differential thermal analysis device and found to be 10% by mass.

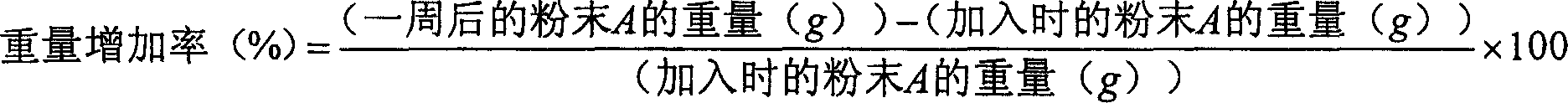

Embodiment 1~3 and comparative example 1

[0062] The L-type HIDS4Na synthesized in Synthesis Example 1 is dried with a tray drier, or it absorbs moisture in a constant temperature and humidity device with a temperature of 25 ° C and a humidity of 80%, and the moisture content of the L-type HIDS4Na is as shown in Table 1. powder composition. 0.5 g of the powder composition was added to 10 g of water at 5° C. to measure the dissolution rate, which was determined by visual comparison with a reference solution. The reference solution uses an aqueous solution in which L-HIDS4Na is pre-dissolved. The time required for dissolution is based on the time when the powder composition is put in, and the solid component is dissolved under stirring. end time point.

[0063] Dissolution rate=(added powder composition (mg, milligram)) / (time required for dissolution (sec, second))

[0064] moisture content

PUM

| Property | Measurement | Unit |

|---|---|---|

| humidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com