Machine made charcoal equipment and method of making charcoal

A technology of mechanism charcoal and equipment, which is applied in the direction of fixed carbonization furnace, special carbonization, solid fuel, etc., can solve the problems of high production cost, time-consuming and laborious, and large investment, and achieve low price, protection of forest ecological environment, and raw materials broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

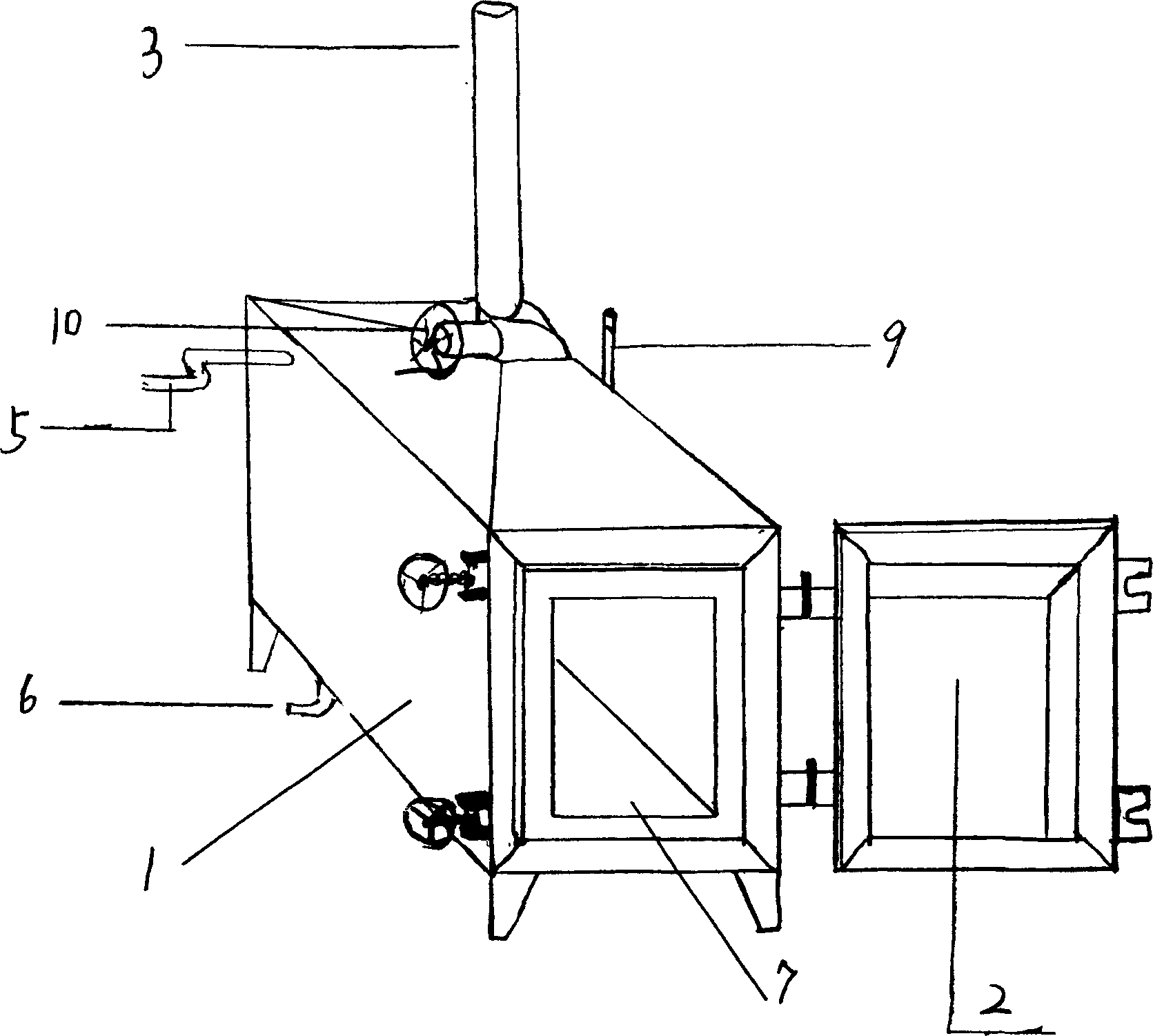

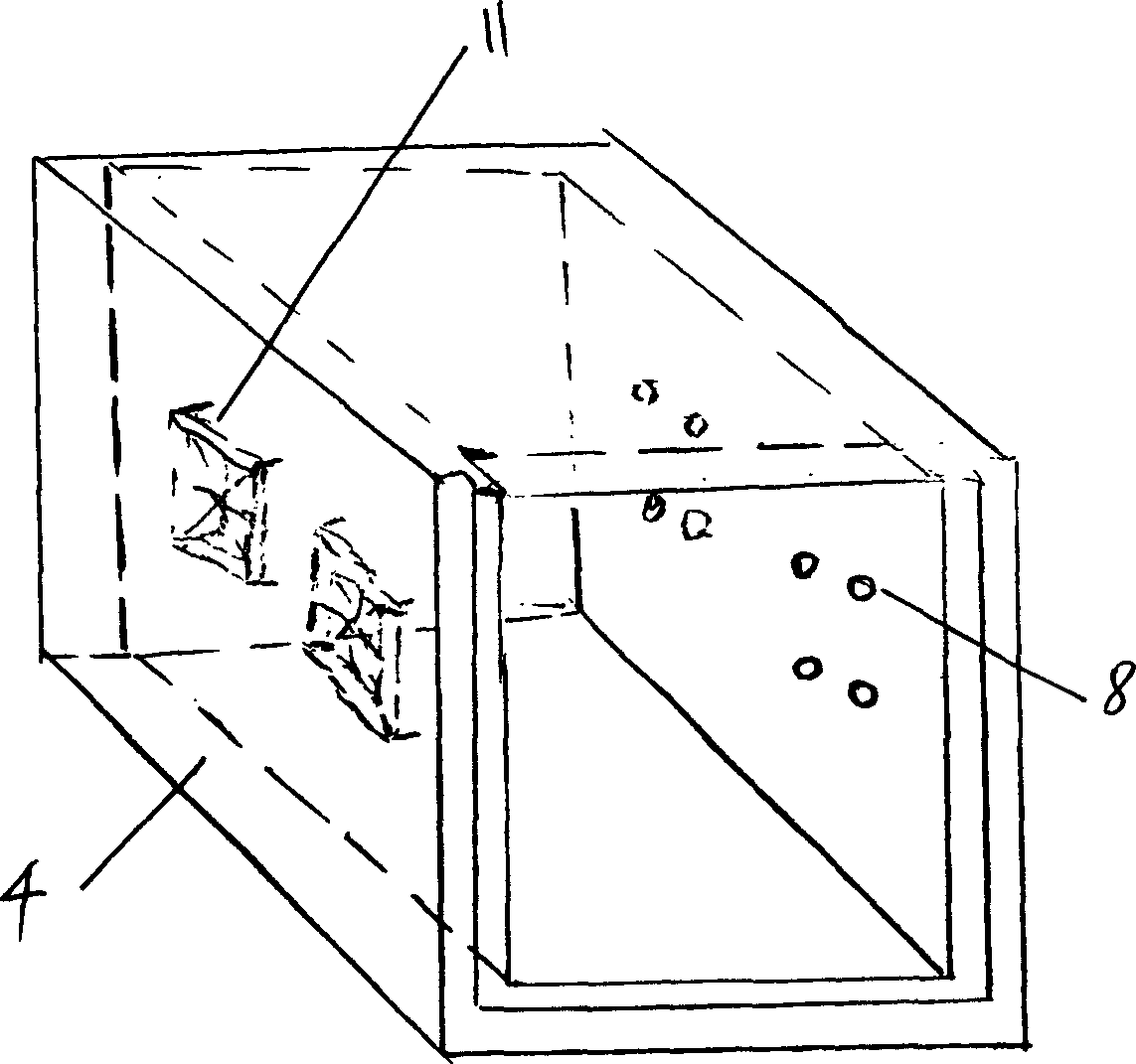

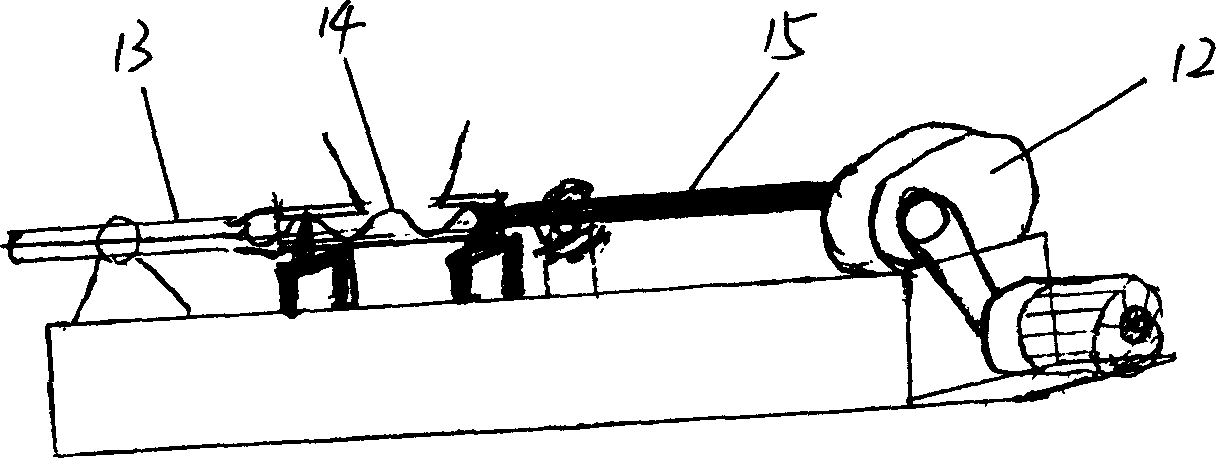

[0019] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a charcoal carbonization furnace and a rod making machine. The charcoal carbonization furnace contains a furnace body 1 and a furnace door 2. A chimney 3 is provided above the furnace body 1. A cavity 4 is provided on the outer wall of the furnace body 1. The upper part of the cavity 4 It is connected with the liquid inlet 5 for carbonization, and the bottom is connected with the liquid outlet 6 for carbonization; the furnace wall between the cavity 4 and the furnace 7 has four groups of micropores 8 that can only enter and exit the gas, and each group is provided with four micropores 8. Four perforators 11 with gaps are arranged in the cavity 4, and four micropores 8 of each group are located in one perforator 11; an exhaust port 9 is provided above the cavity 4; the chimney 3 and An oxygen supply and control switch 10 is installed at the junction of the furnace bod...

Embodiment 2

[0022] Test item name

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap