Film forming method

A film-forming method and film-forming technology, used in gaseous chemical plating, coatings, electrical components, etc., can solve problems such as poor step coverage, and achieve the effects of reducing impurities, increasing film-forming speed, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

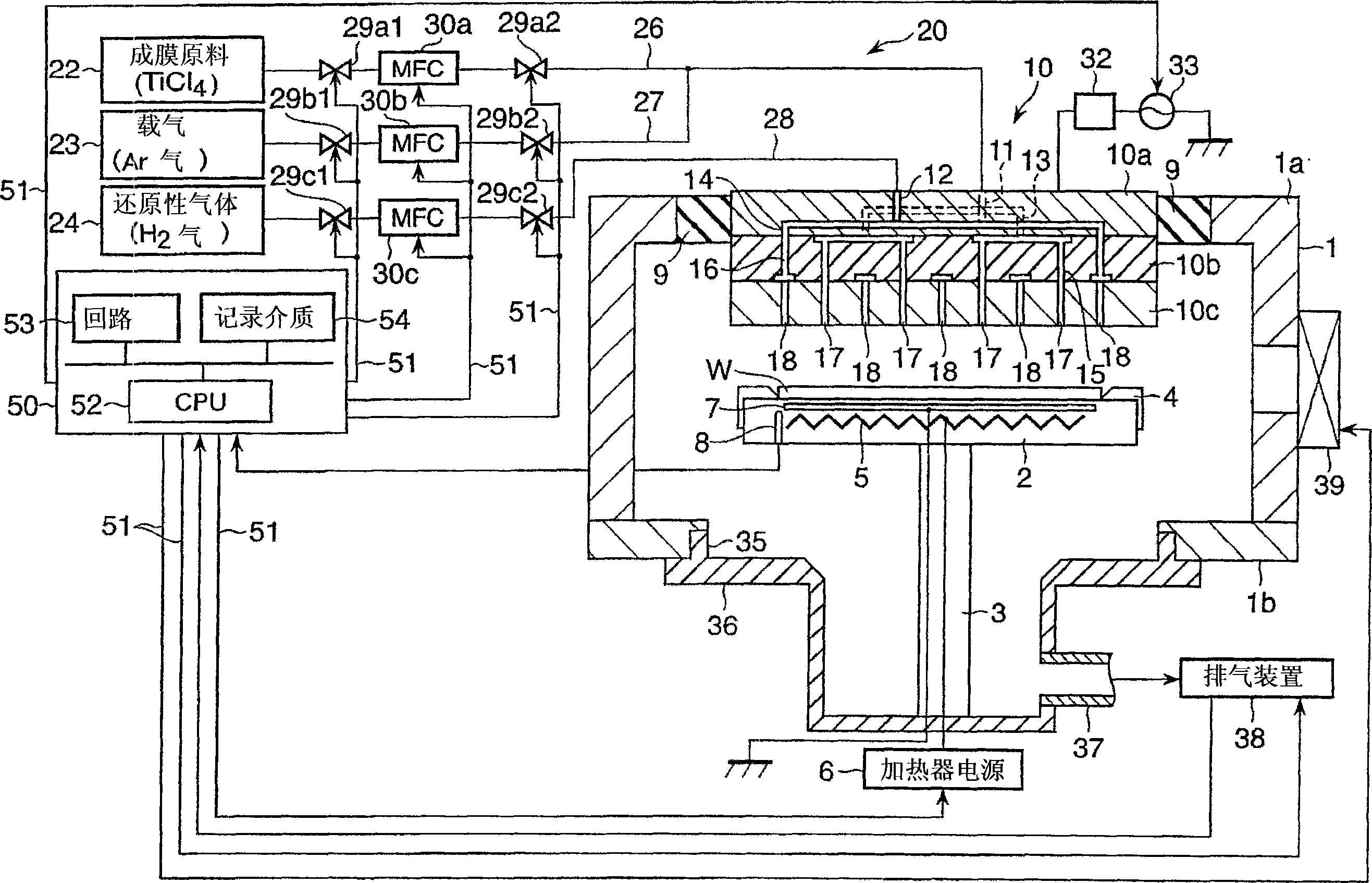

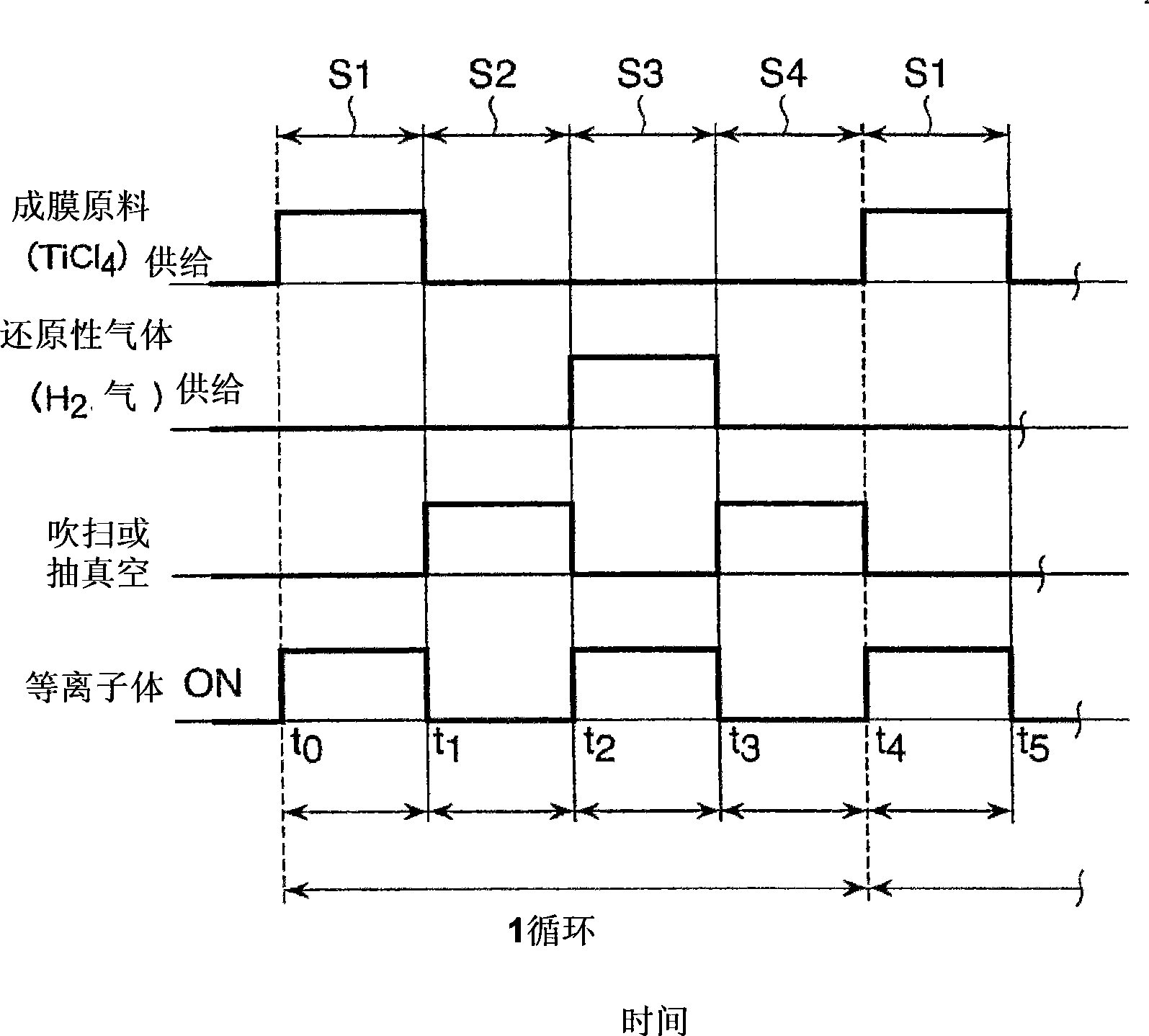

[0031] Various preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0032] Such as figure 1 As shown, various functional elements of the film forming apparatus 10 of this embodiment are connected to a control computer 50 that automatically controls the operation of the entire film forming apparatus via a signal line 51 . Here, the so-called functional requirements include heater power supply 6, valves 29a1-29c2, mass flow controllers (MFC) 30a-30c, high-frequency power supply 33, exhaust device 38, gate valve 39 and other peripheral devices. All the elements for operating in the apparatus 10 to realize predetermined film-forming process conditions. Here, only a part of the many signal lines 51 is illustrated for convenience. The control computer 50 is a typical general-purpose computer that can realize arbitrary functions depending on the software it runs.

[0033] The control computer 50 has a central computi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com