Method for treatment of wool washing waste water

A treatment method, wool washing technology, applied in centrifugal separation water/sewage treatment, osmosis/dialysis water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of large sulfuric acid consumption, complicated equipment, troublesome maintenance, etc. , to achieve the effects of reducing emissions, reducing water consumption, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

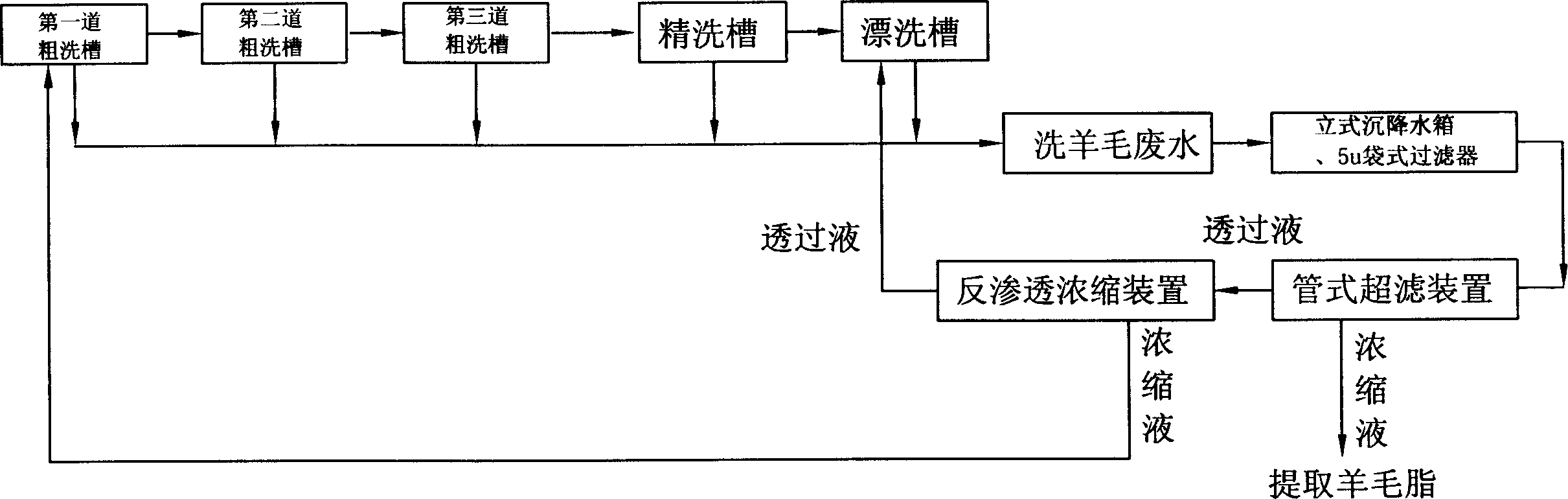

[0021] Refer to attached picture. The processing method of the wool washing wastewater provided by the present invention, it comprises the following processing steps successively to the wool washing wastewater:

[0022] 1) Pretreatment, through sedimentation and other pretreatment processes to remove solid impurities such as sand in the wool washing wastewater, so as to ensure the stable operation of the subsequent membrane system. As shown in the figure, after being settled in a vertical settling water tank, it is filtered through a 5μ bag filter and then enters the next process for treatment.

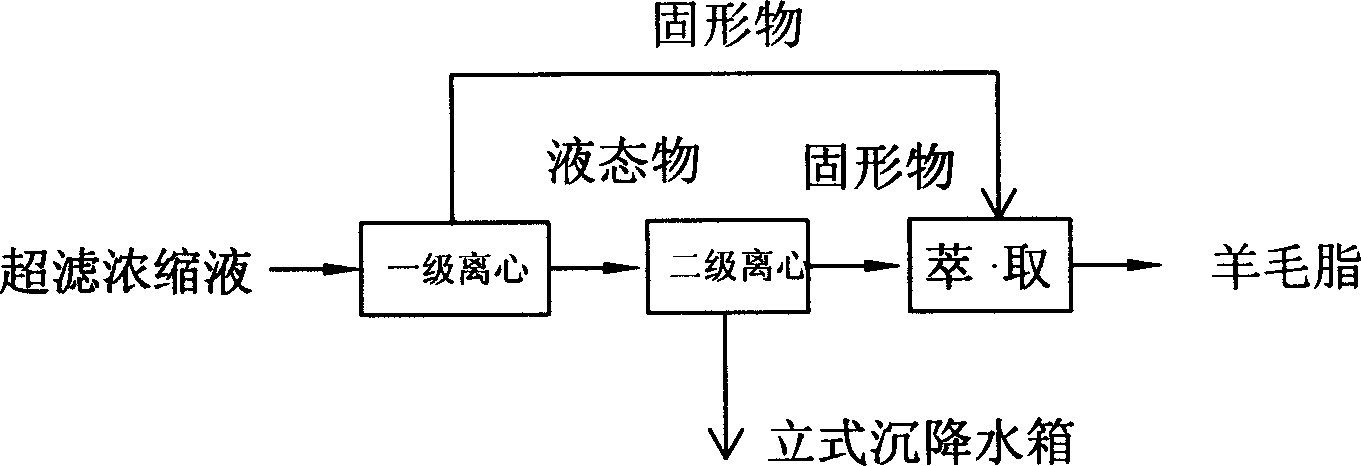

[0023] 2) The pretreated wool washing wastewater is sent to the ultrafiltration system through the delivery pump for ultrafiltration treatment. Using the screening mechanism of the ultrafiltration membrane, organic matter with different molecular weights and different particle sizes is separated. After treatment, the lanolin is recovered from the ultrafiltration concentrate, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com