Methods for manufacturing flux cored wire for welding stainless steel and products thereof

A technology of flux-cored welding wire and manufacturing method, applied in welding/welding/cutting items, welding medium, manufacturing tools, etc., can solve the problems of poor conductivity, poor arc stability, poor welding performance and manufacturing process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

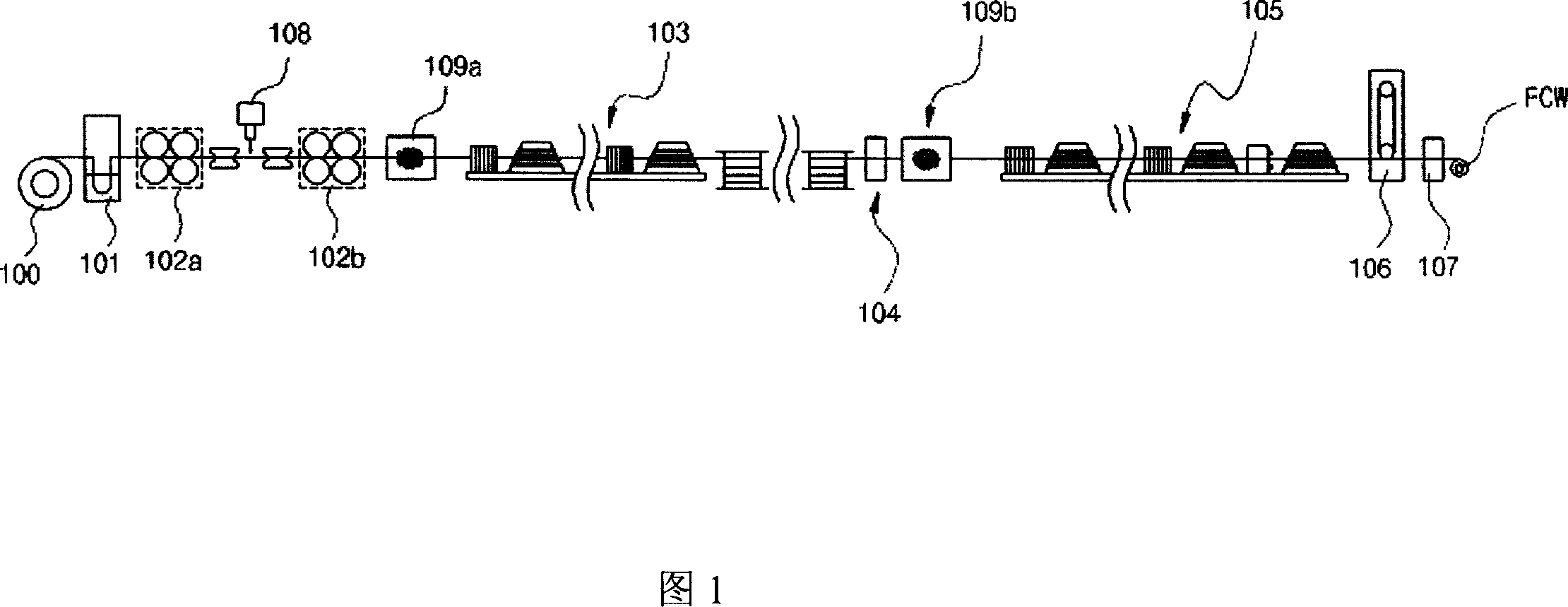

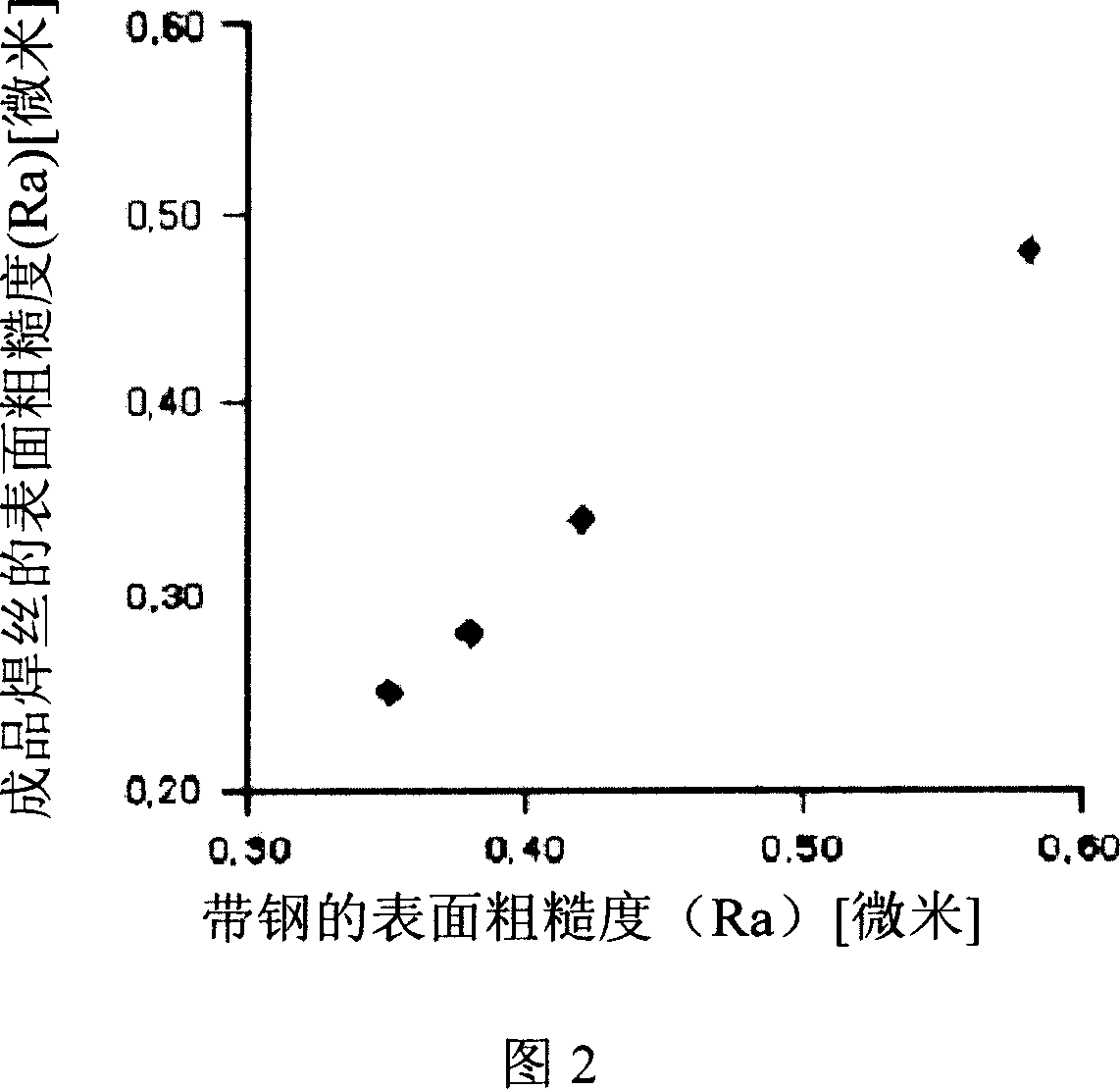

[0066] A stainless steel strip (100) having the composition shown in Table 1 was cleaned and degreased (101). One of the fluxes shown in Table 2 is selected and filled (108), and formed (102) into a tube shape using forming rollers (102a and 102b). Next, lubricants 109a and 109b selected from Table 3 were coated on the steel strip and drawn in two steps. Prior to the drawing process, at least 10 flux mixtures including rutile sand, silica and iron powder were used. Each flux was mixed and heated at or above 950°C for at least 1 hour. The moisture content evaporated into the air was calculated by the reduction in weight method and the result was expressed as the total moisture content relative to the weight of the flux mixture. In particular, in order to discover the effect of the total moisture content of the flux mixture, the inventors of the present invention stockpiled various raw materials, or selected different flux raw materials as the source of the same oxide. The fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com