Apparatus and method for recovering carbon disulfide in hydrogen sulfide gas during preparing process of carbon disulfide

A technology of carbon disulfide and hydrogen sulfide, which is applied in the field of separation of gas mixtures, can solve problems such as environmental pollution, economic loss, and reduction of catalyst activity, and achieve the effects of protecting the environment, reducing the concentration of sulfur dioxide, and increasing the concentration of acid gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

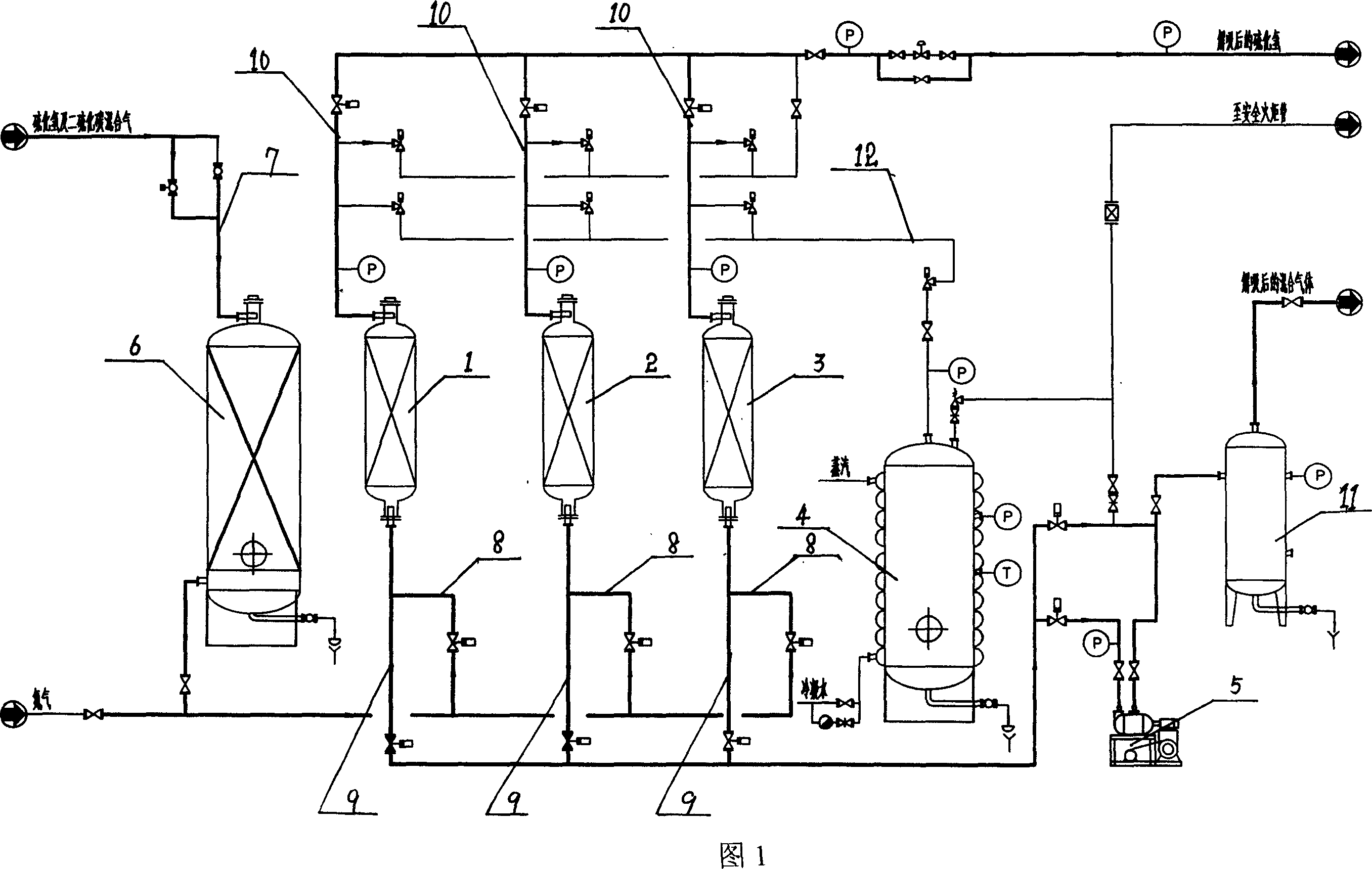

[0011] The equipment for recovering carbon disulfide in hydrogen sulfide gas in the preparation of carbon disulfide includes at least two adsorption reactors. The mixed gas input branch pipe 8 connected with the mixed gas input main pipe 7 is respectively connected under the adsorption reactor. The carbon disulfide output branch pipe 9 communicated with the gas input branch pipe 8, the carbon disulfide output branch pipe 9 is connected with the vacuum desorption pump 5 respectively, the hydrogen sulfide output pipe 10 is respectively arranged above the adsorption reactor, and valves are respectively installed on each pipe; There is also an adsorption buffer tank 4 between the desorption pumps 5, and the top of the adsorption buffer tank 4 is respectively connected to the hydrogen sulfide output pipe 10 and the vacuum desorption pump 5 through a vacuum pipeline 12; preprocessor6.

[0012] Utilize the above-mentioned equipment for recovering carbon disulfide in hydrogen sulfide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com