Process for improving the co-polymerization of ethylene and an olefin co-monomer in a polymerization loop reactor.

An olefin comonomer and loop reactor technology, applied in the field of olefin polymerization, can solve problems such as difficulty in controlling reaction parameters, and achieve the effects of less temperature oscillation, improved fluctuation, and reduced risk of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

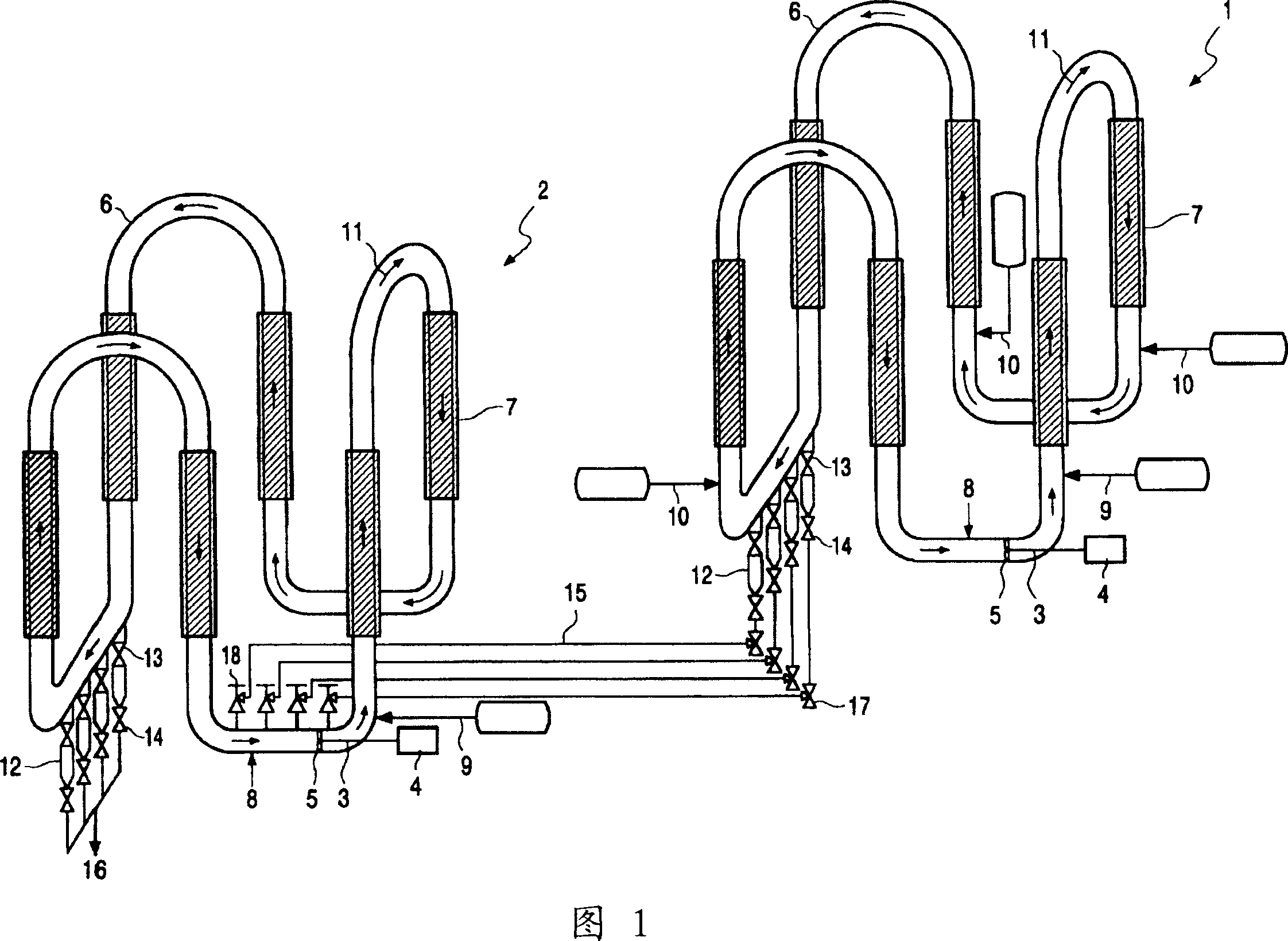

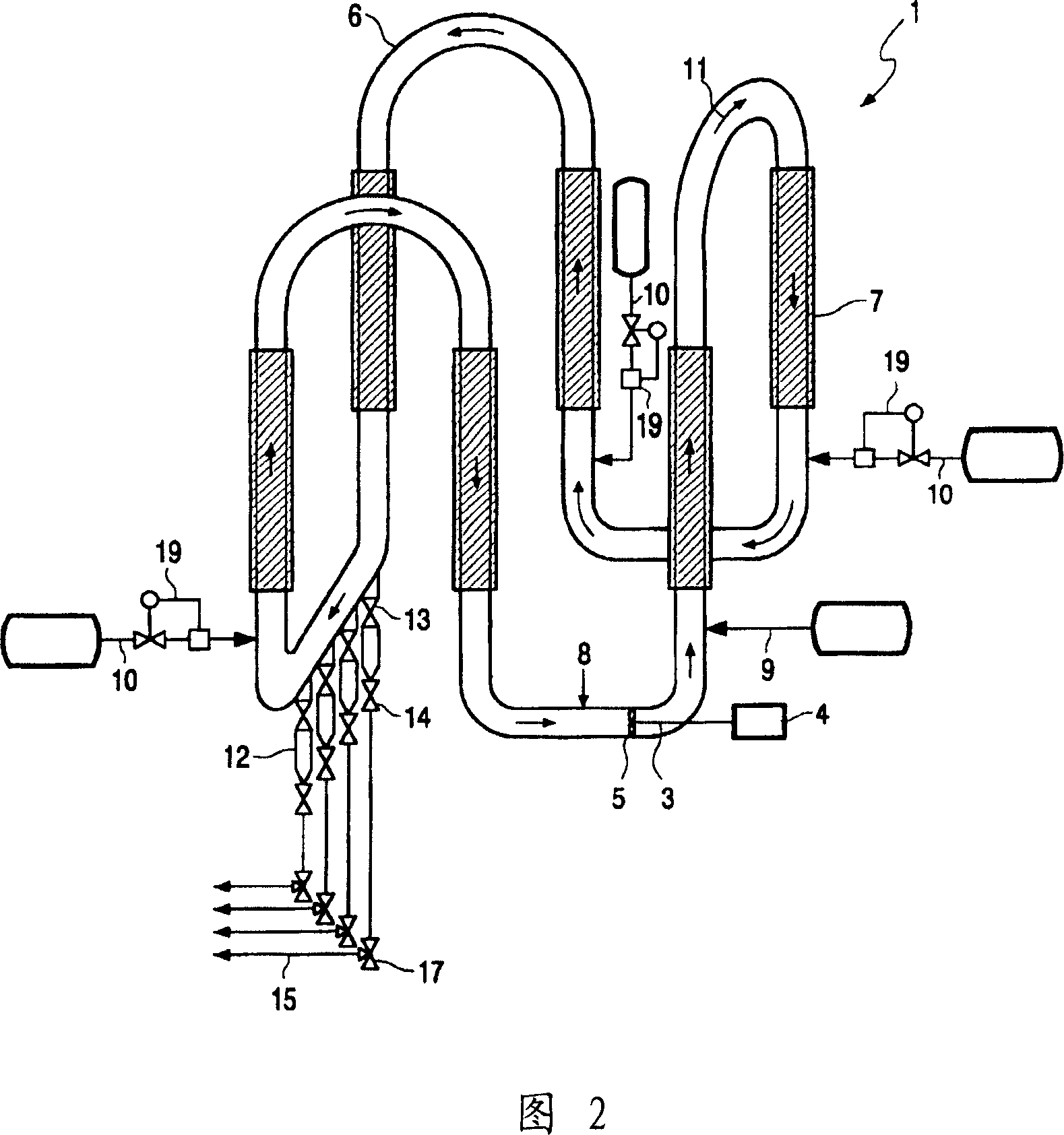

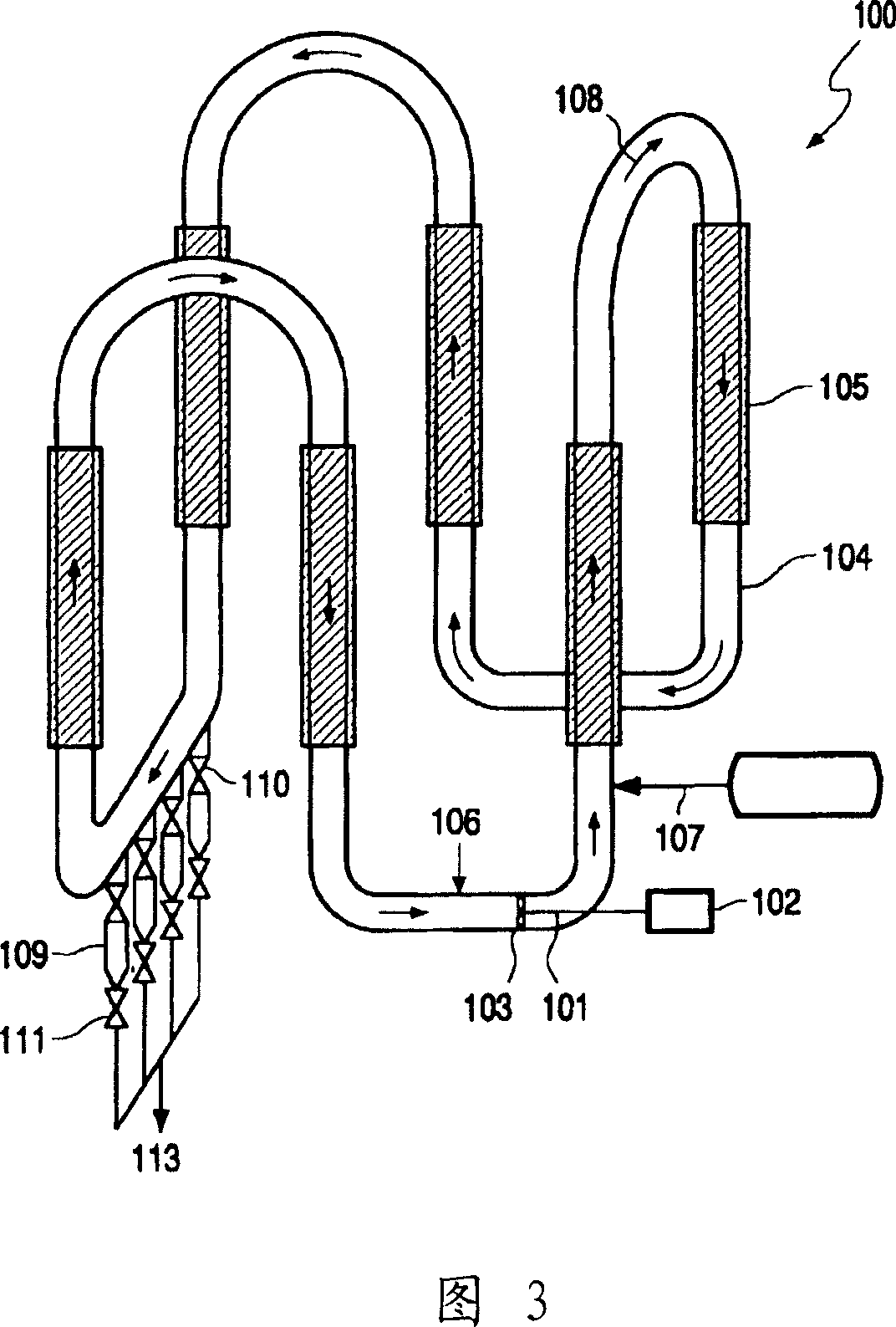

[0026] The invention is particularly applicable to the copolymerization process of ethylene and olefin comonomers in a polymerization loop reactor. The term "ethylene copolymerization" includes the copolymerization of ethylene and olefinic comonomers. Polymerization of ethylene involves feeding to a reactor reactants comprising monomeric ethylene, light hydrocarbon diluent, catalyst, comonomer and optionally a cocatalyst and a terminator such as hydrogen. The term "copolymer" means a polymer prepared by linking two different types on the same polymer chain.

[0027] Olefin comonomers suitable according to the present invention may include, but are not limited to, aliphatic C 3 -C 20 alpha-olefins. suitable aliphatic C 3 -C 20 Examples of alpha-olefins include propylene, 1-butene, 4-methyl-1-pentene, 1-hexene, 1-octene, 1-decene, 1-dodecene, 1-tetradecene ene, 1-hexadecene, 1-octadecene and 1-eicosene. The invention is specifically described with reference to the copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com