Modified SU8 electric heating micro-performer with multi-arc structure for straight line propulsion

A micro-actuator and modification technology, which is applied in the field of modified SU8 electrothermal micro-actuators, can solve the problems of large action environment influence, high driving voltage, small thermal deformation coefficient, etc., and achieve small environmental impact, small operating current, The effect of increased conductivity

Inactive Publication Date: 2011-01-05

SHANGHAI JIAOTONG UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the case where large displacement is required, due to the small thermal deformation coefficient of silicon, it is often necessary to increase the current to heat the Si component, and then obtain a large thermal deformation method to achieve it. There is an excessively high driving voltage, especially when the displacement is large during operation. The high temperature has a great impact on the operating environment, which limits its application and other deficiencies

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

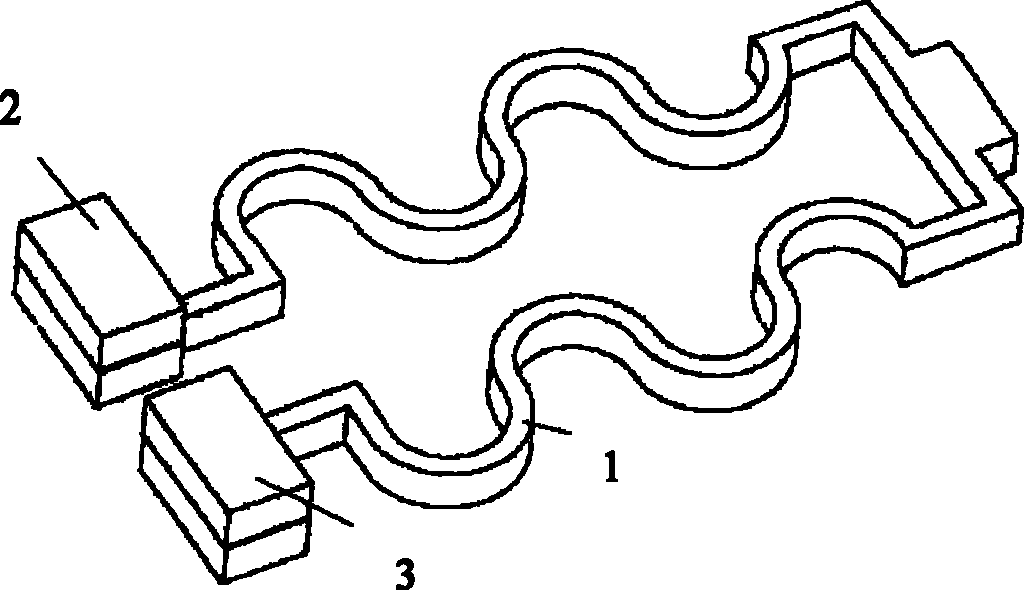

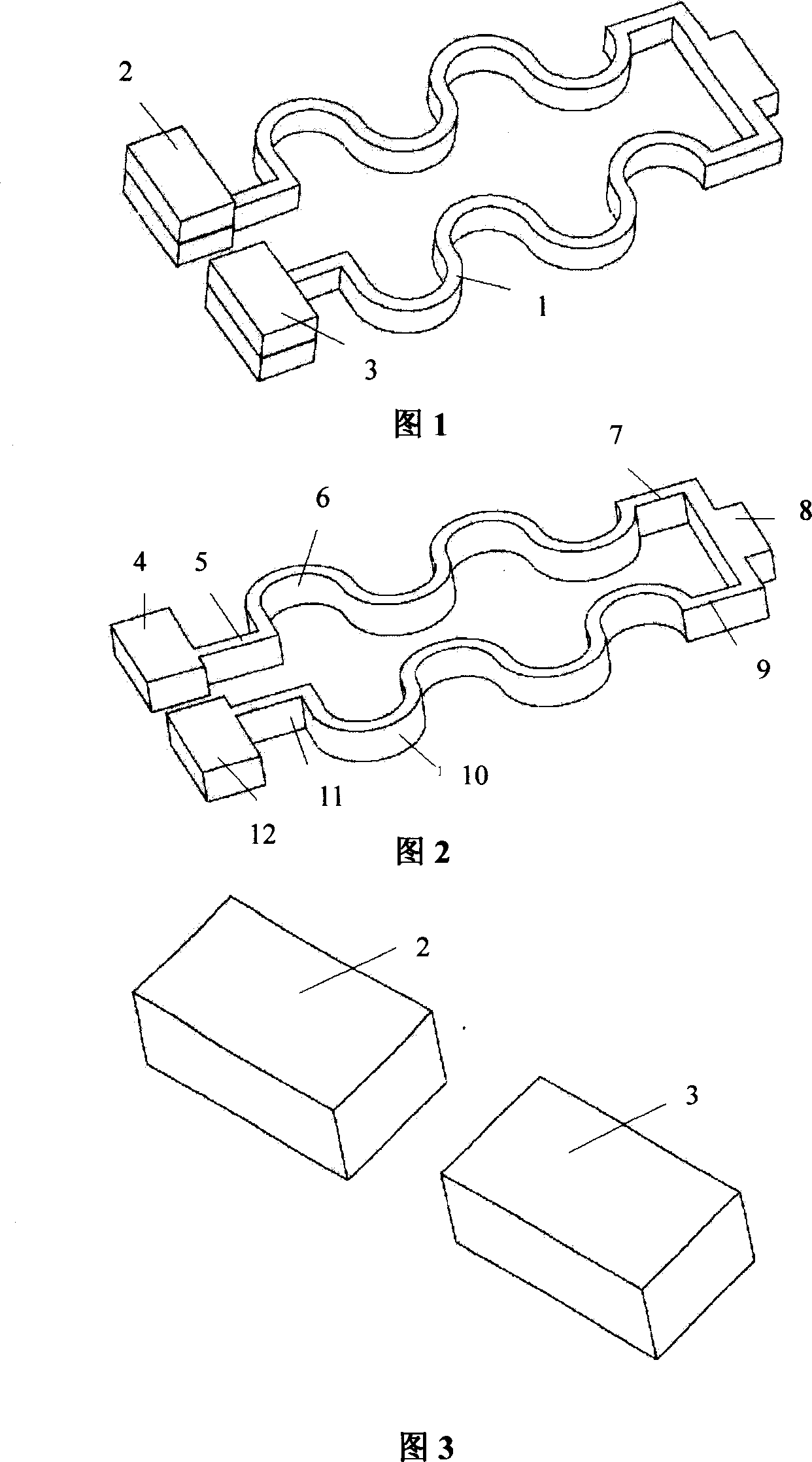

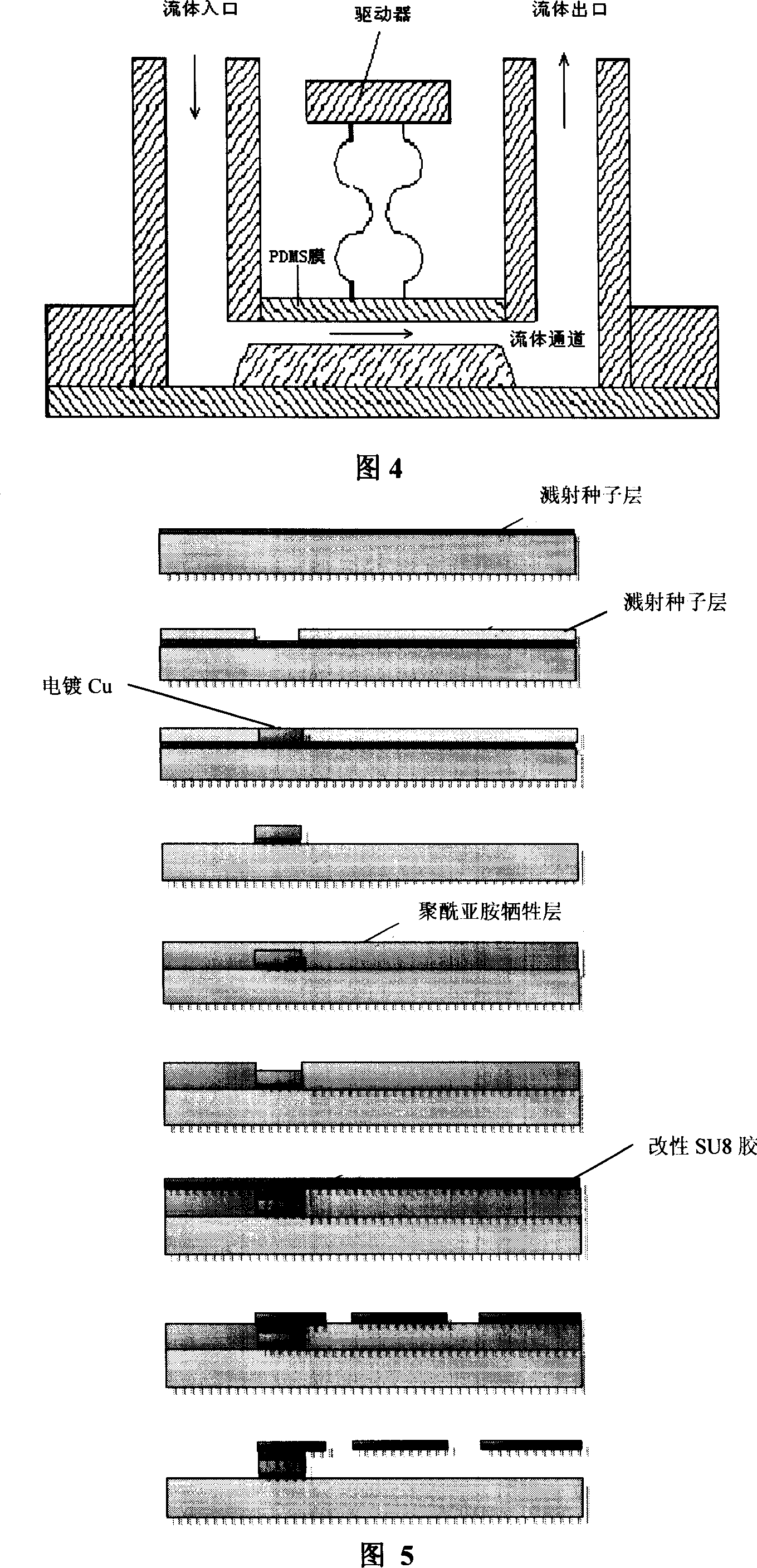

This is a modified SU8 electric heat micro performer for multi arc straight line thrusting device, and it belongs to the MEMS micro manufacturing techniques. Comprised of the SU8 cantilever beam, the left conductive layer connected to the outside circuit, and the right conductive layer, its SU8 cantilever beam is multi arc structured for straight line trusting, made on the glass base and the beamis made of the SU8 glue blended with nanometer carbon tube, and the top of the SU8 glue cantilever beam of the left and right conductive layers connect with the glass base through the left conductivelayer and the right conductive layer in the below. This cantilever structure is highly increased in mechanical intensity and conductivity and it is beneficial to reduce the operating current and operating temperature.

Description

Modified SU8 electrothermal microactuator with multi-arc structure for linear propulsion technical field The invention relates to a device in the technical field of MEMS micro-manufacturing, in particular to a modified SU8 electrothermal micro-actuator with a multi-arc structure for linear propulsion. Background technique Micro-actuator is one of the key components of Micro-Electro-Mechanical Systems (MEMS). At present, micro-actuators based on various principles have been widely studied at home and abroad. The most widely used micro-actuation methods include electrostatic actuation, piezoelectric actuation, electromagnetic actuation, thermal actuation, and shape memory alloy actuation. However, the electric or magnetic actuation method has disadvantages such as complex manufacturing process, high driving voltage, non-linear driving force, too small driving force and the like. Relatively speaking, the thermal driving method is attractive because of its small geometric siz...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B81B3/00

Inventor 张卫平陈实陈文元

Owner SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com