Apparatus and method of synthesizing acidic material on SiO2 surface by eliminating gas phase method

An acidic substance and deacidification technology, applied in the direction of silicon oxide, etc., can solve the problems of product yield decline, expensive equipment, high energy consumption, etc., and achieve the effects of increasing yield and PH value, reducing energy consumption, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

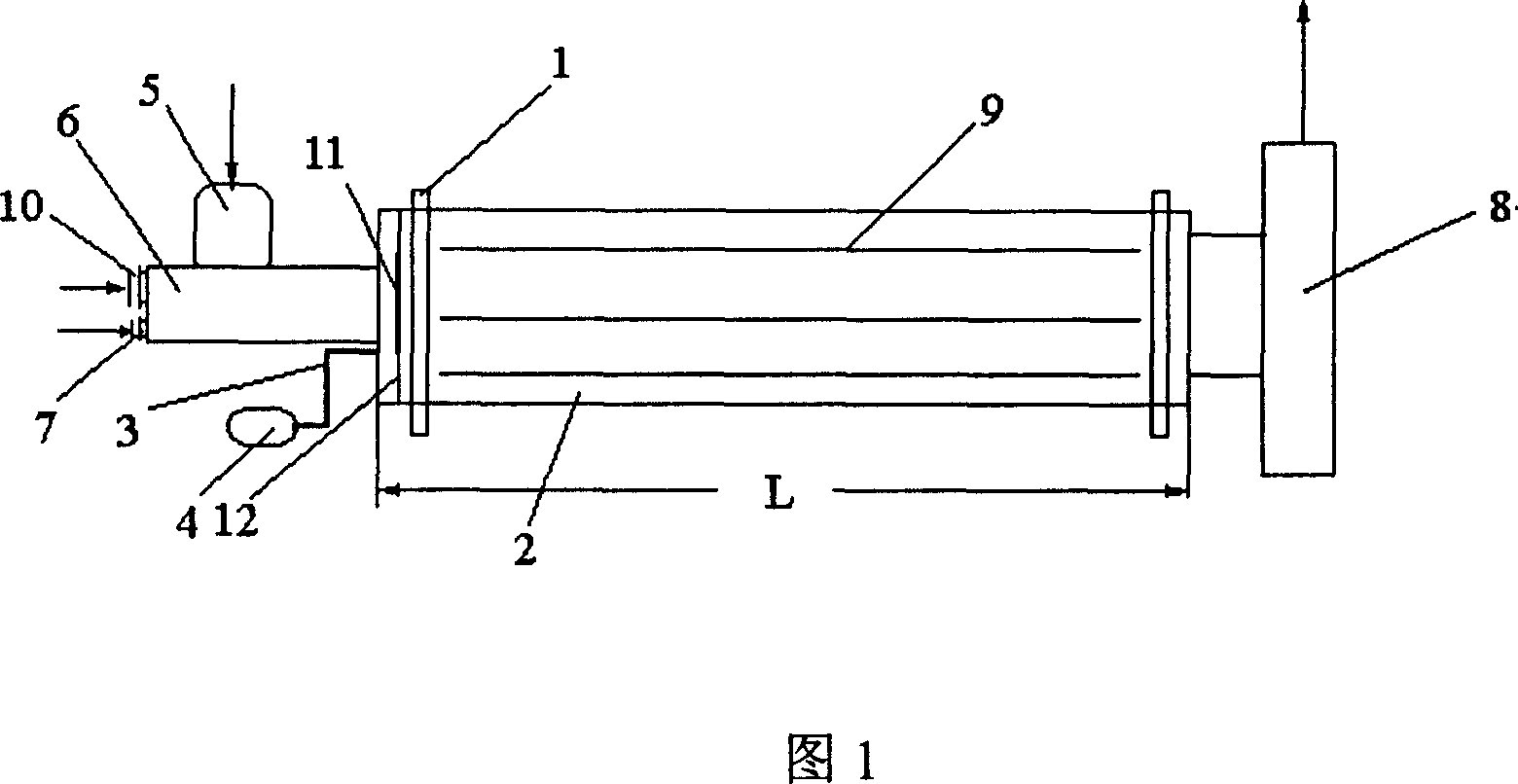

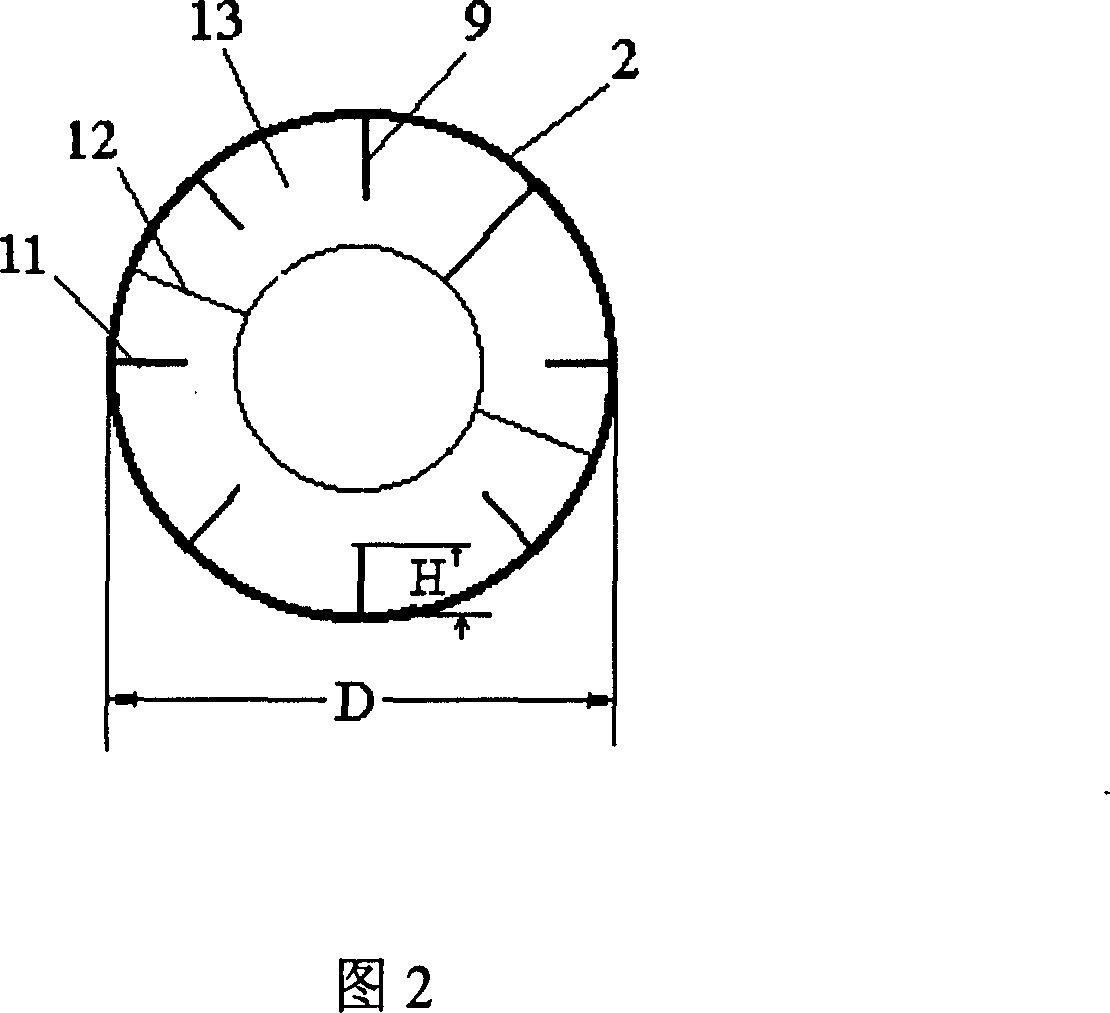

[0037] Adopt the device of Fig. 1, Fig. 2 and Fig. 3, wherein, structural parameters are as follows:

[0038] The internal diameter D=0.3 meter of deacidification furnace, length=3 meters, be provided with 6 lifting plates 9, evenly distributed, the width of lifting plate 9 is 0.05 meters;

[0039] Raw material: white carbon black crude product, the pH of 4% aqueous solution is 2.

[0040] Send the mixture of 5 kg / h of white carbon black crude product and 6 m / h of nitrogen and 8 m / h of water vapor into the deacidification furnace 2 through the feeding device, and start the motor at the same time to drive the deacidification furnace to rotate through the rotating shaft , use hydrogen combustion to heat, control the temperature in the deacidification furnace to 400°C, the product after deacidification is sent to the subsequent section for processing by the discharge collector;

[0041] The residence time of white carbon black coarse product in the deacidification furnace is 30 ...

Embodiment 2

[0045] Adopt the device of Fig. 1, Fig. 2 and Fig. 3, wherein, structural parameters are as follows:

[0046] The internal diameter D=0.6 meter of deacidification furnace, length=6 meters, be provided with 4 lifting plates 9, evenly distributed, the width of lifting plate 9 is 0.10 meters;

[0047] Raw material: white carbon black crude product, pH of 4% aqueous solution is 2.5.

[0048] Send the mixture of 10 kg / h of white carbon black crude product, 6 m / h of nitrogen and 8 m / h of water vapor into the deacidification furnace 2 through the feeding device, and start the motor at the same time to drive the deacidification furnace to rotate through the rotating shaft , using electric heating to control the temperature in the deacidification furnace to 450°C, the product after deacidification is sent to the subsequent section for processing through the discharge collector;

[0049] The residence time of white carbon black coarse product in the deacidification furnace is 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com