Water-based derusting anticorrosion paint

A technology for anti-corrosion and coating with rust, applied in the direction of anti-corrosion coatings, coatings, latex paints, etc., can solve the problems of inability to control the conversion degree of rust reaction, difficulty in grasping the relationship between the thickness of the rust layer, and the inability to be widely used, etc., to achieve improvement Excellent construction environment, excellent rust removal ability, and improved inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

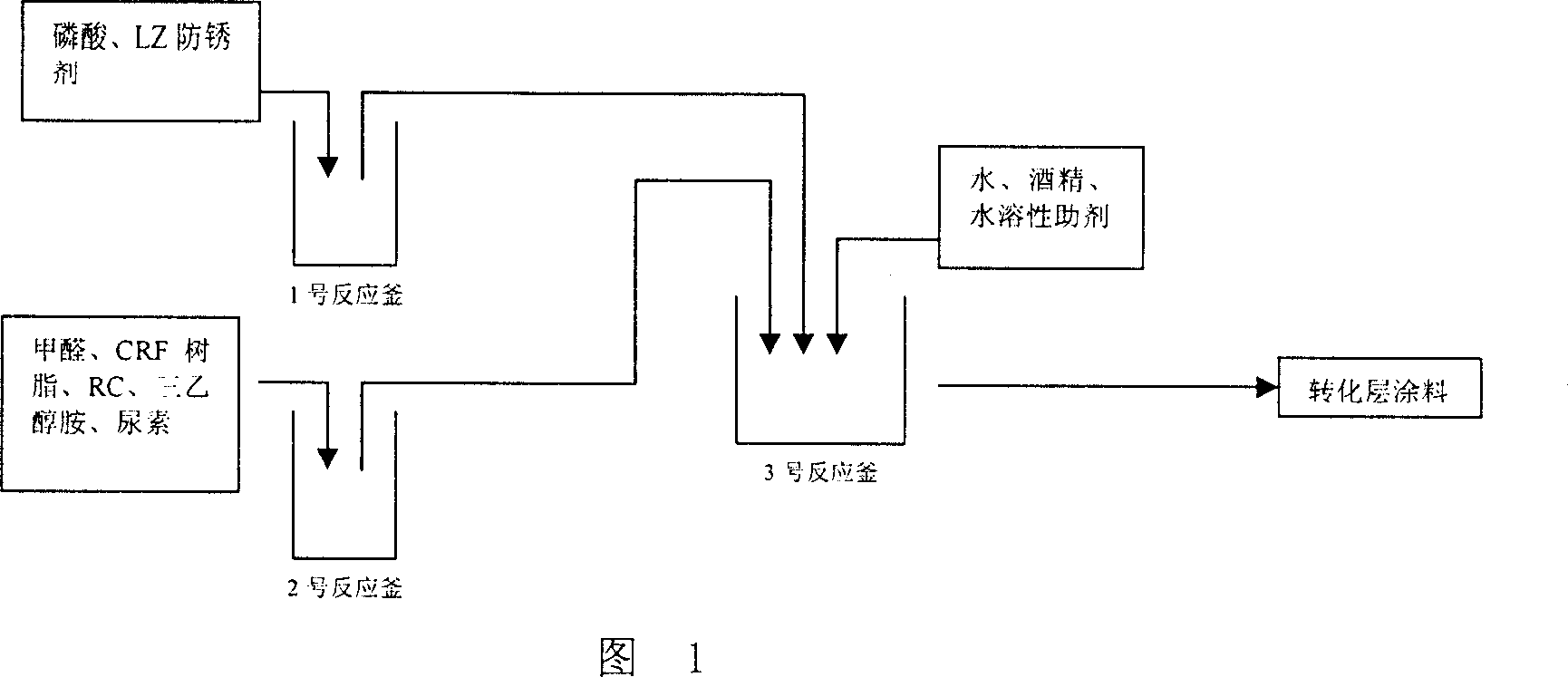

[0048] 1. Conversion coating formula (parts by weight)

[0049] Formula 1: CRF resin 22, phosphoric acid (85%) 370, RC dispersant 11, LZ rust inhibitor 3;

[0050] Formula 2: CRF resin 22, phosphoric acid (85%) 370, RC dispersant 11, LZ rust inhibitor 3, triethanolamine 6, formaldehyde (35%) 27, alcohol (>95%) 60, urea 6, water 40, Additives (JX adhesion promoter (50%), JP rheology modifier (50%)) 2;

[0051] Formula 3: CRF resin 20, phosphoric acid (85%) 350, RC dispersant 10, LZ rust inhibitor 2, triethanolamine 5, formaldehyde (37%) 25, alcohol (>95%) 60, urea 6, water 40, Additives (JX adhesion promoter (50%), JP rheology modifier (50%)) 1;

[0052] Formula 4: CRF resin 25, phosphoric acid (85%) 380, RC dispersant 12, LZ rust inhibitor 3, triethanolamine 8, formaldehyde (35%) 30, alcohol (>95%) 80, urea 8, water 20, Additives (JX adhesion promoter (50%), JP rheology modifier (50%)) 3;

[0053] Wherein, the concentrations of phosphoric acid and formaldehyde are both in ...

Embodiment 2

[0082] The electrostatic conduction properties of the paint film formed by the conversion layer (formula 2) and the anti-corrosion layer (formula 3) in Example 1 were tested. The result shows that this paint film has electrostatic conduction property, and the primer surface resistance is 10 6 Ω, the volume resistivity is 10 6 Ω.M, in line with GB13348 Petroleum Static Safety Regulations and GB6950 Petroleum Can Static Conductive Coating Technical Specifications and other relevant domestic and foreign regulations (see Table 5), and this product has proved its reliability and safety in actual experiments.

[0083] Country names

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com