Boundary effect infiltrated glaze of imitating natural stone texture and manufacture method

A technology of imitating natural stone and infiltration, which is applied in the field of raw materials and preparation of ceramic tiles, can solve the problems of high local water content of green bodies, cracks in polished tile products, and reduced production quality, and achieves a soft and delicate overall decorative surface. , The overall decorative surface is more, and the effect of texture blur is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

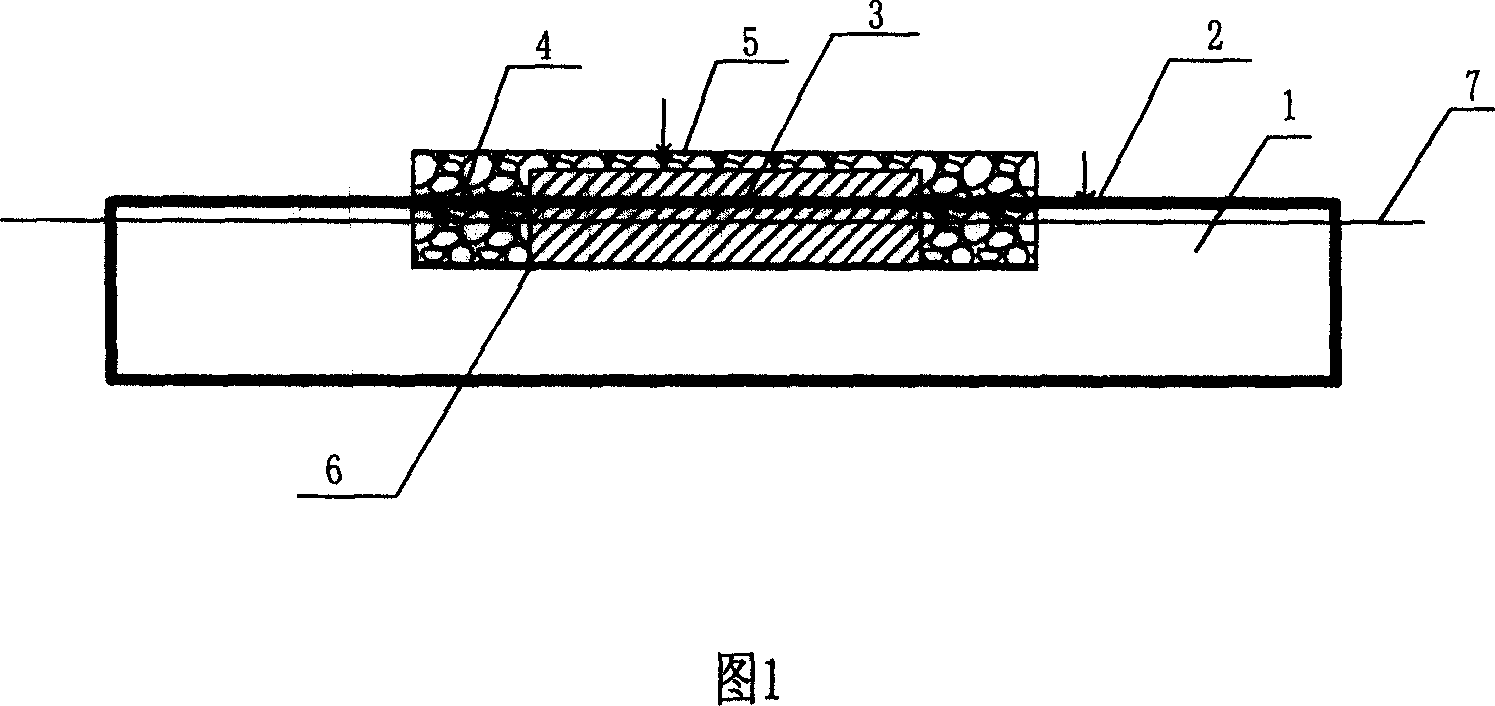

Image

Examples

Embodiment Construction

[0022] The present invention is a boundary effect oozing glaze imitating the texture of natural stone, which adopts the following raw material components and proportioning (by weight): SnCl 2 150 grams, 20 grams of sodium citrate, 30 grams of HCl, 10 grams of ethylene glycol, 2 grams of carboxymethyl cellulose, H 2 O 100 grams.

[0023] Since tin can whiten the body of seeped tiles, but it also has the same generality as ammonium fluorozirconate, it needs to be dissolved in a large amount of aqueous solution to achieve the whitening effect, and in the existing tin Among the compounds, only stannous chloride (SnCl 2 ) solubility is the largest, but SnCl 2 However, when it meets water, it will be hydrolyzed into a basic stannous chloride [Sn(OH)Cl] with little solubility. 2 ]precipitation. It applies the following chemical principles:

[0024]

[0025] In order to solve the SnCl 2 For the difficult problem of water precipitation, the present invention adopts to dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com