Method for making field transmitting triode

A manufacturing method and triode technology, applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problem of poor uniformity of aperture, distribution uniformity, and poor vertical alignment, which affects the diameter of nanometer carbon tubes Uniformity, distribution uniformity, vertical alignment, cathode line disconnection and other issues, to achieve the effect of improving tube diameter uniformity, improving field emission characteristics, and high process temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

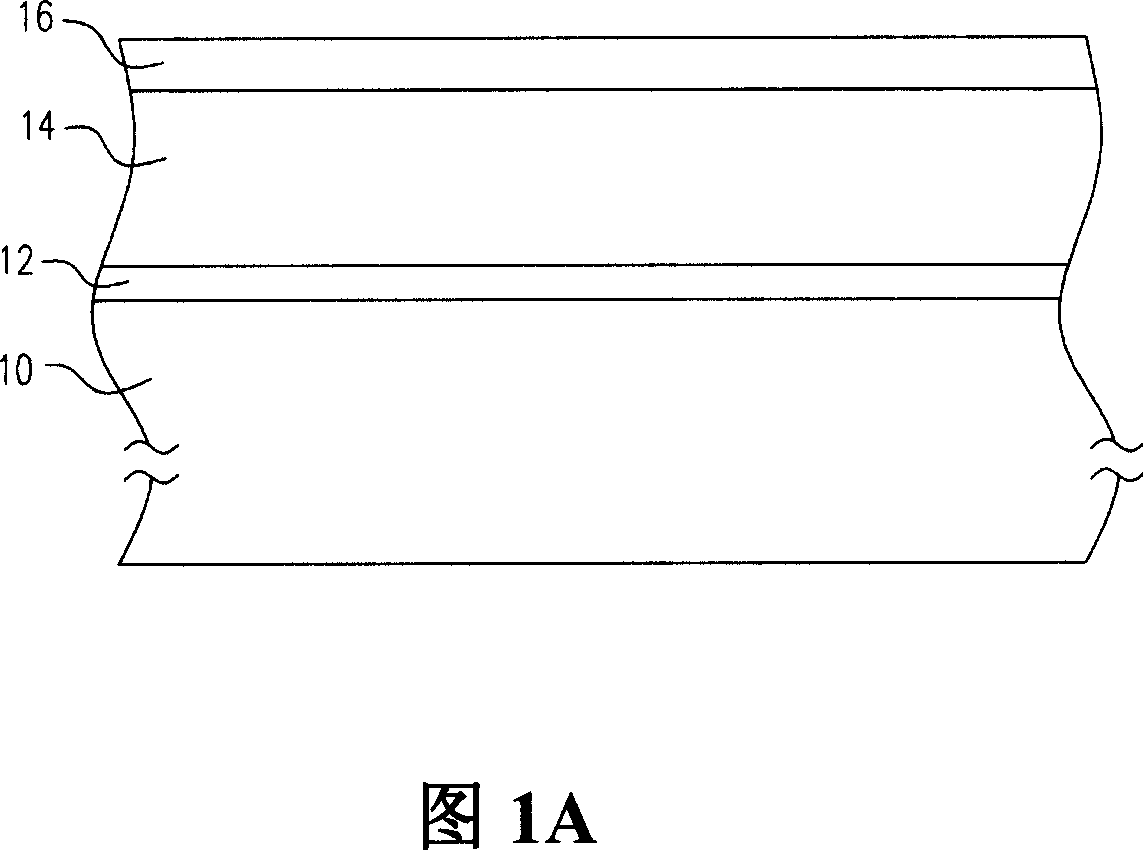

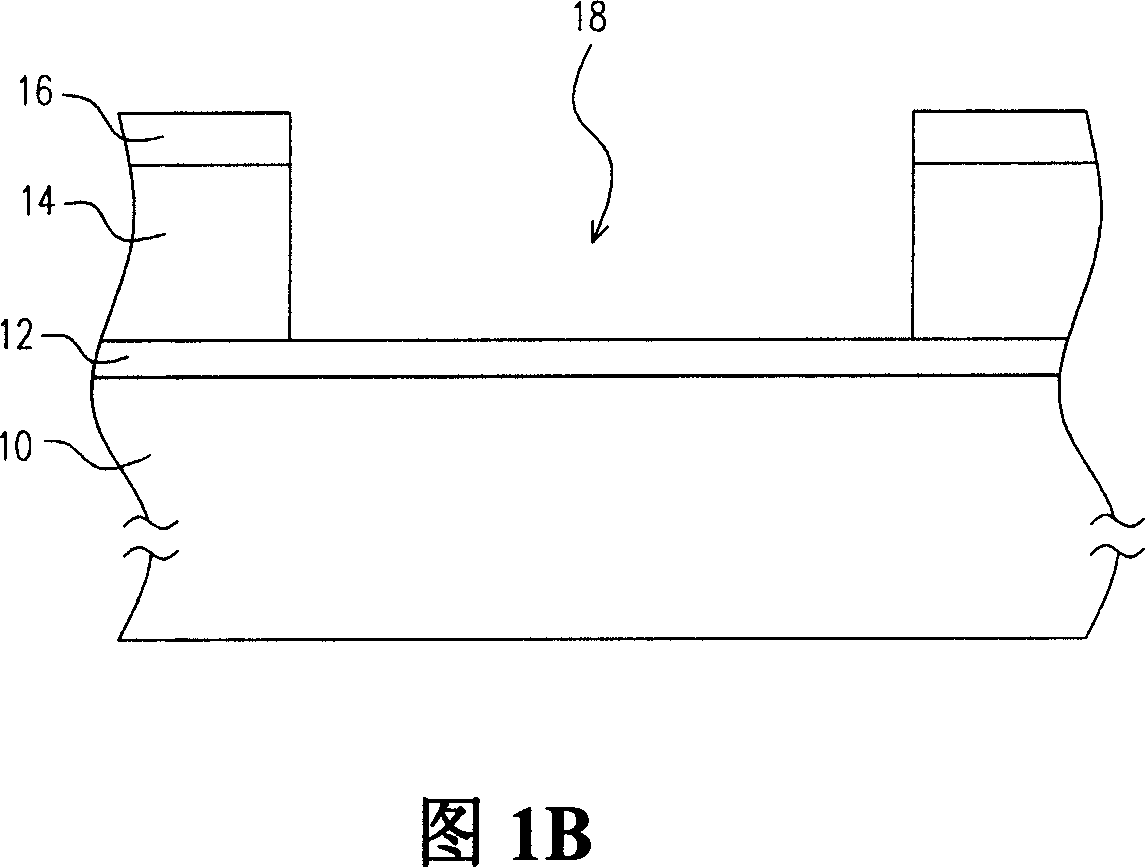

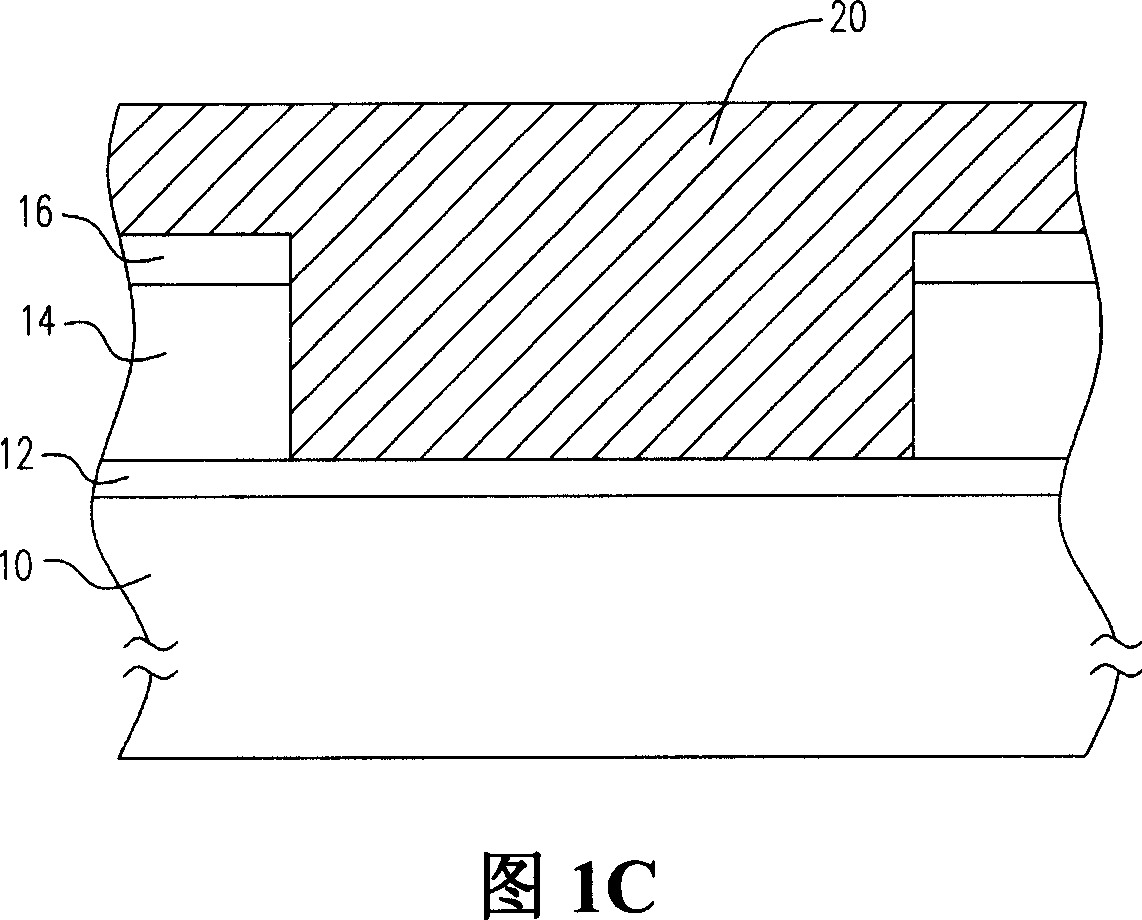

[0035] 1A to 1H are partial cross-sectional schematic diagrams of the manufacturing process of a field emission triode element of the present invention. Please refer to FIG. 1A. First, a cathode conductive layer 12, an insulating layer 14 and a gate layer 16 are sequentially formed on a substrate 10. . The substrate 10 is, for example, a silicon substrate or a glass substrate. The cathode conductive layer 12 is a cold cathode conductive material used as a field emission triode element, and its material is, for example, single-layer or double-layer metal, alloy, metal nitride or doped semiconductor. The cathode conductive layer 12 can also provide good adhesion between the substrate 10 and the insulating layer 14 , and its thickness is about 0.05 μm to 0.5 μm. In a preferred embodiment, the material of the cathode conductive layer 12 is, for example, titanium, titanium nitride, tantalum or tantalum nitride. The above materials can withstand a process temperature above 800° C.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com