Glass-fiber reinforced thermo-setting resin inspection manhole cover

A glass fiber and thermosetting technology, which is applied in the field of glass fiber reinforced thermosetting resin inspection manhole covers, can solve the problems of poor bonding between the surface and the resin, large differences in thermal expansion coefficient, rust on the surface of steel bars, etc. Excellent fatigue performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

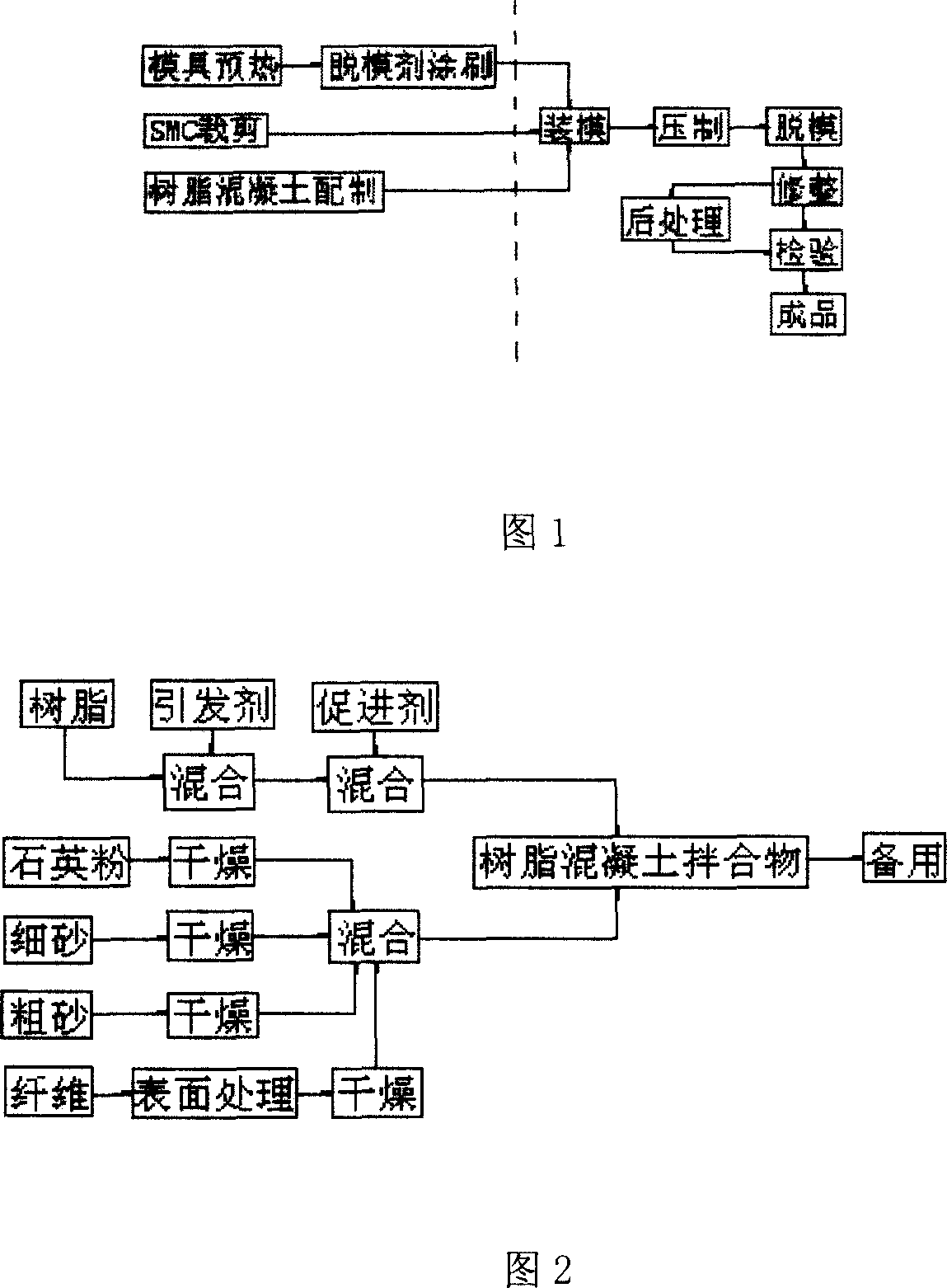

[0017] The technical scheme of the glass fiber reinforced thermosetting resin inspection manhole cover of the invention is realized in the following way: SMC sheet molding compound and resin concrete are made by molding, and the molding process flow chart is shown in Figure 1.

[0018] Before the molding process, the SMC sheet molding compound should be trimmed. SMC sheet molding compound has a great influence on the molding process and product quality, so you should first understand the quality of SMC sheet molding compound, such as resin paste formula, glass fiber content, unit weight, film peelability, quality uniformity, etc. , and clipping. When cutting, the shape and size of SMC sheet molding compound cutting should be determined according to the structure of the manhole cover and the feeding position. First, make a model, and then cut the material according to the model. In order to prevent contamination from external impurities, the upper and lower films of the SMC sh...

Embodiment 2

[0022] The preparation process of resin concrete is shown in Figure 2. The ingredients and parts by weight of resin concrete are: 100 parts of unsaturated polyester resin, 2 parts of initiator, 0.1-2 parts of accelerator, 0.3 parts of durafiber, 100 parts of quartz powder, 215 parts of fine sand, and 255 parts of coarse sand . Wherein the initiator is a methyl ethyl ketone peroxide solution; the accelerator is a styrene solution containing 6% cobalt naphthoate; the length of the durafiber is 19mm, and it should be surface treated before use: the durafiber is loosened and coupled in silane After soaking in the agent solution KH-560, take it out and dry it before use; the quartz powder is 100-200 mesh, the diameter of fine sand is 0.15-1.2mm, and the diameter of coarse sand is 1.2-5.0mm.

[0023] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com