Method for processing high-boiling-point solvant essence before gas-phase colour-spectrum mass-spectrum combined detection

A gas chromatography mass spectrometry, high boiling point solvent technology, applied in the field of high boiling point solvent essence treatment, can solve the problems of the loss of effective components of the essence, slow adsorption process, unfavorable adsorption, etc., to reduce the loss of effective components, improve the recovery efficiency, shorten the The effect of payback time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

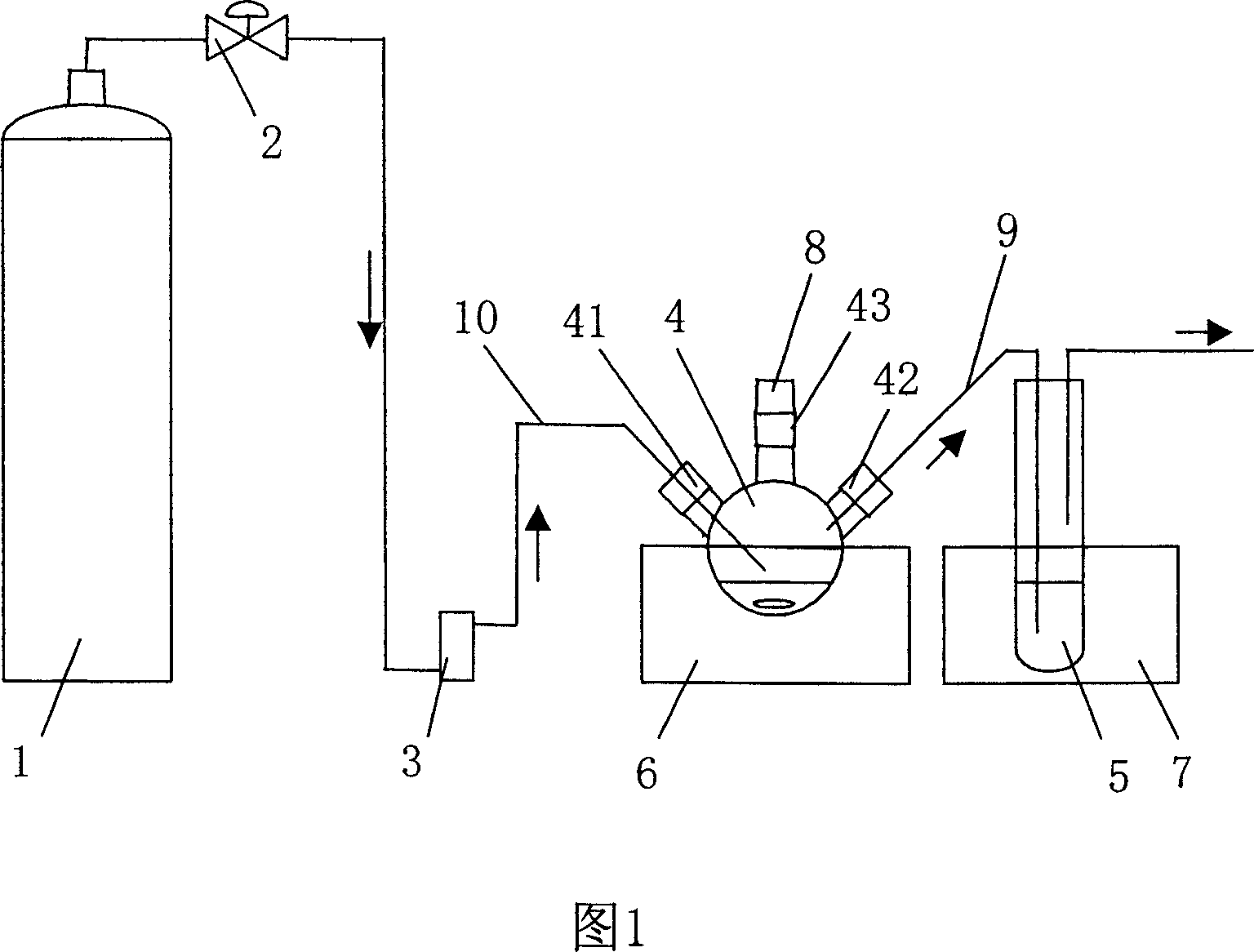

[0035] As shown in Figure 1, connect the nitrogen cylinder 1 directly to the pressure reducing valve 2, then connect the gas outlet of the pressure reducing valve 2 to the air inlet of the flowmeter 3, and then connect the gas outlet of the flowmeter 3 with the high boiling point solvent essence to be processed The three-necked flask 4 of the sample is then used to receive the active component gas carried out by the condenser tube 5 equipped with a low-temperature receiving solvent.

[0036] The three-necked flask 4 is put into the water bath 6, and the water temperature of 30° C. to 80° C. is more suitable. Put the condenser tube 5 into the cold trap 7. The condensation temperature of the cold trap 7 should be controlled at -25°C to -15°C. The temperature difference between the high and low temperature of the cold trap 7 should be above 5°C to protect the condensate pump and open the cycle.

[0037] One side bottle mouth 41 of wherein said three-necked flask 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com