Dry cleaning system using a laser

A purification system and laser technology, applied in the field of dry purification systems using lasers, can solve problems such as environmental pollution and discharge of sewage and waste water, and achieve the effect of simple cleaning automation process, improving test efficiency, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

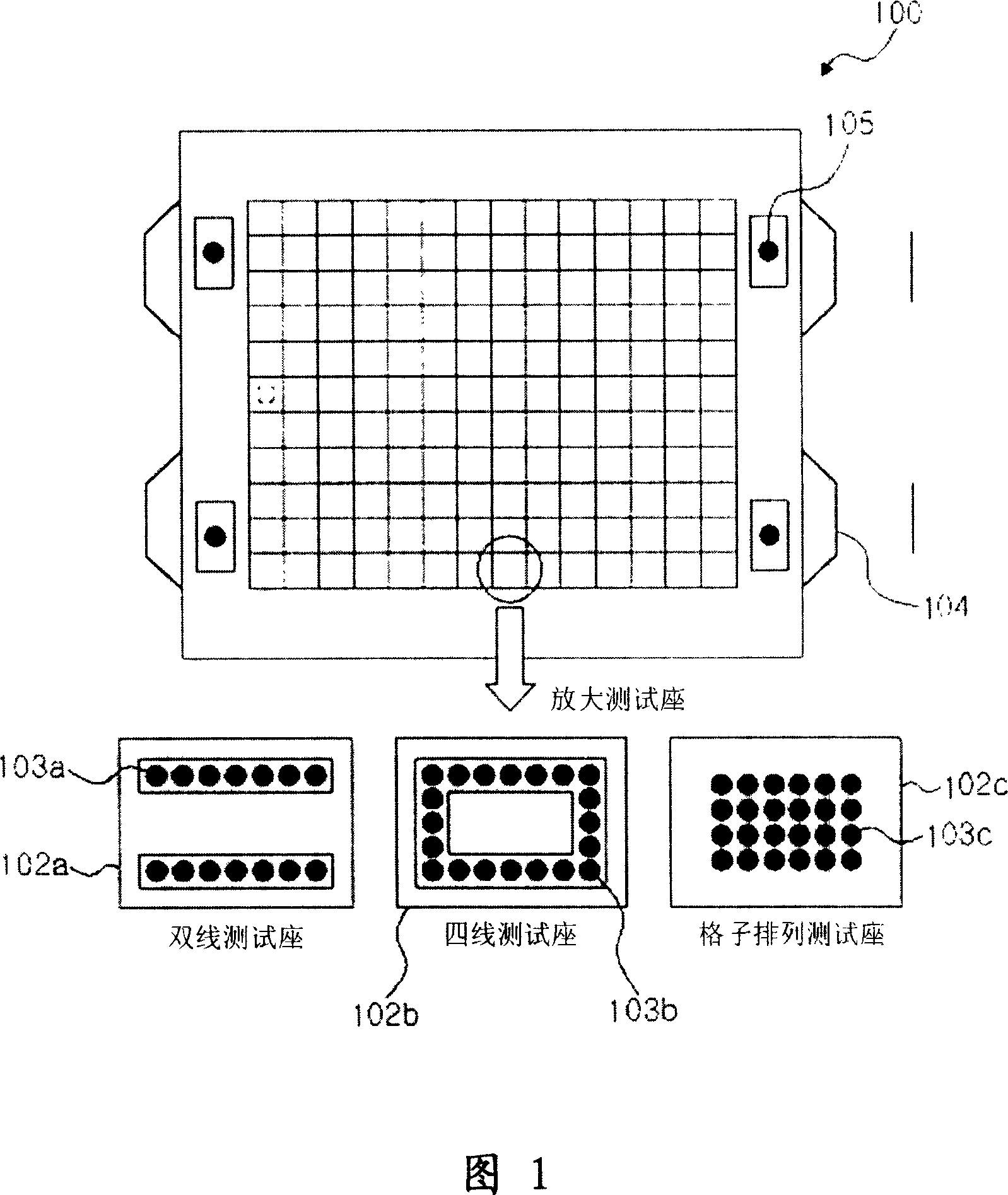

[0048] Below, the preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. In the accompanying drawings of the following embodiments, the objects to be cleaned include but are not limited to the semiconductor test seat board and the test seat contact portion thereon, and probe cards for wafer testing, etc. can also be used as cleaning objects.

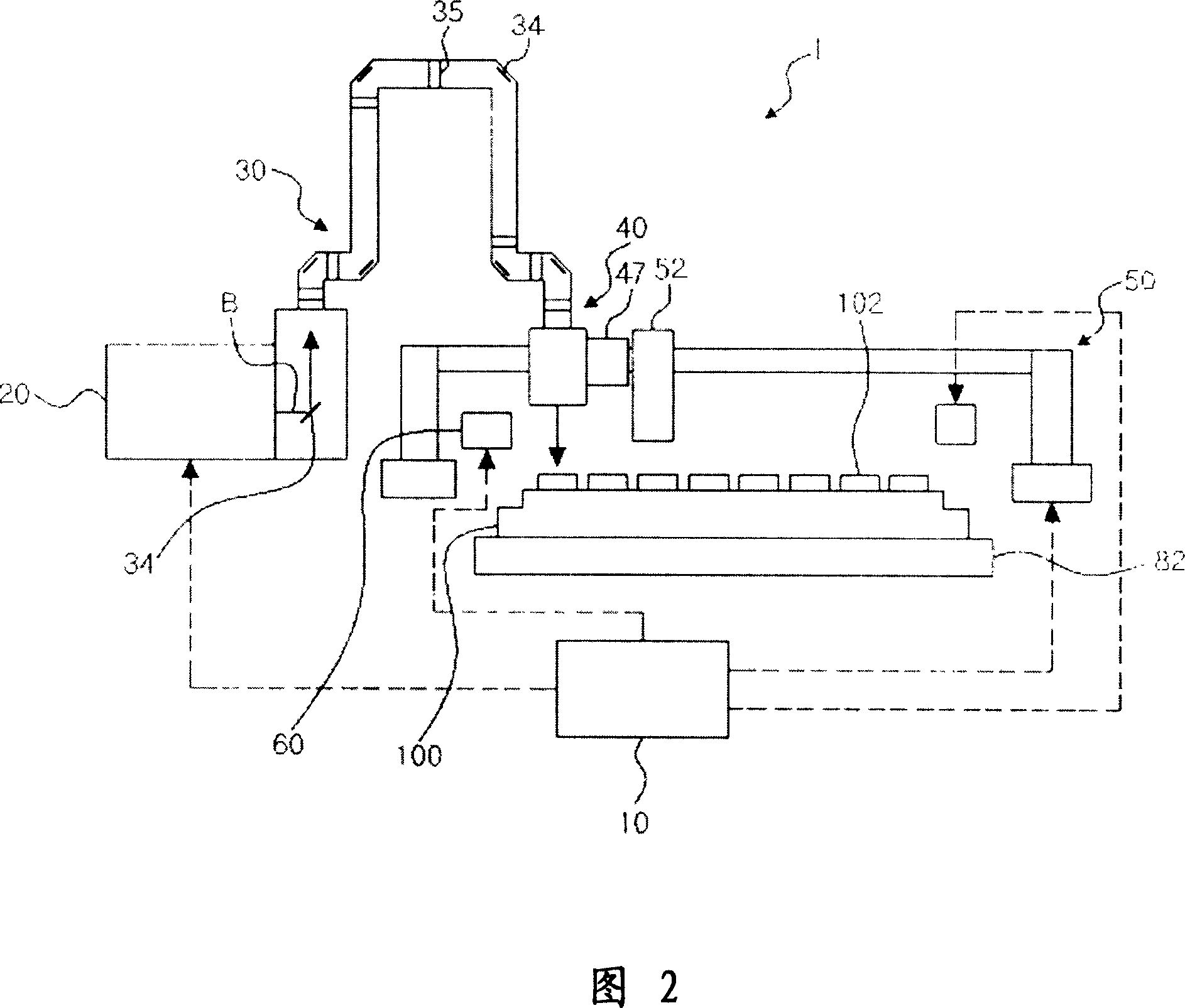

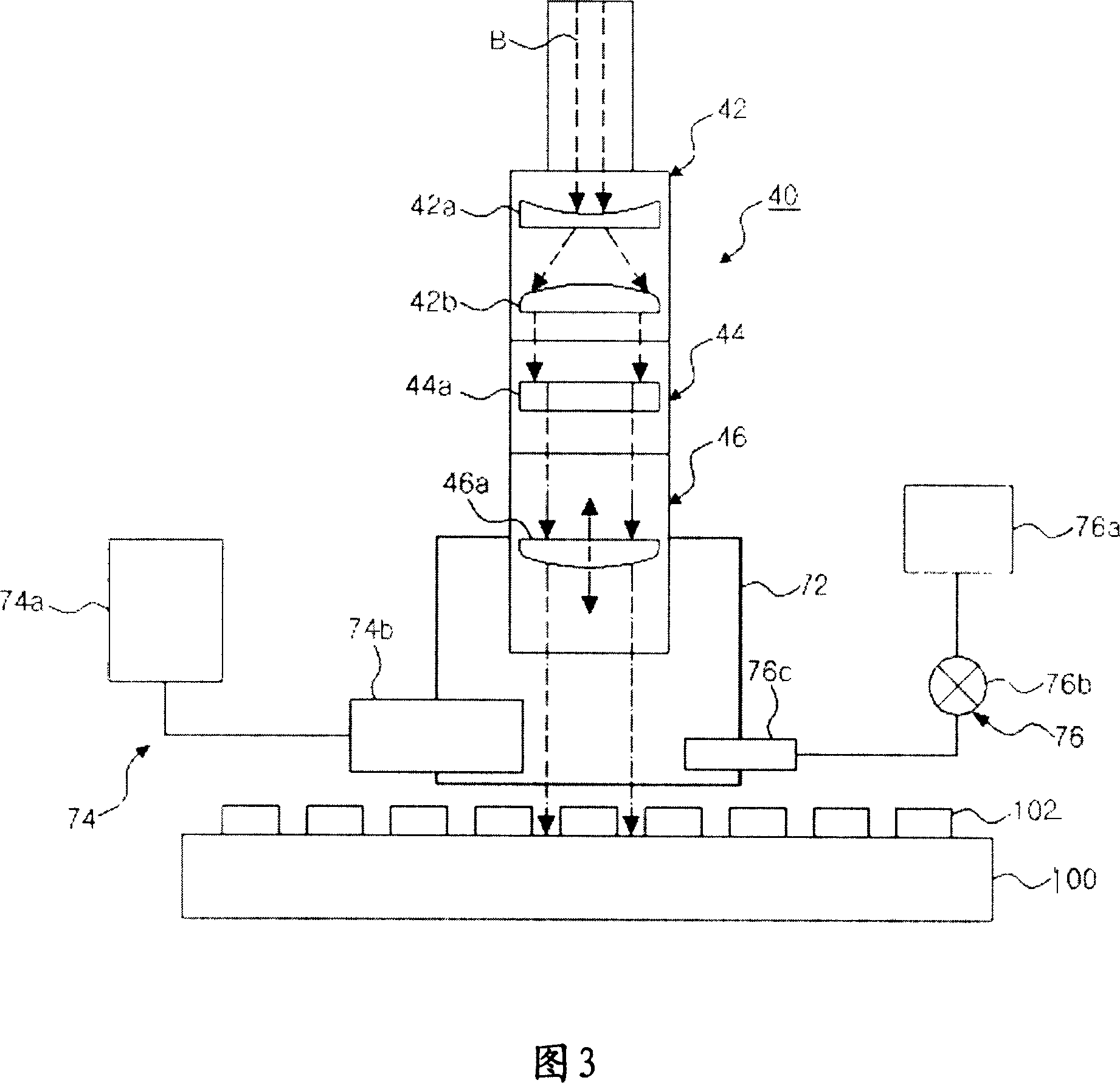

[0049] Please refer to FIG. 2 , which is a schematic diagram of a dry cleaning system for dry-cleaning semiconductor test sockets in an embodiment of the present invention. Fig. 3 illustrates the main parts of the dry cleaning system in Fig. 2, and is a schematic diagram of a laser beam irradiation device for irradiating objects to be cleaned with laser beams. Fig. 4 is a schematic diagram of a carrying device for loading the cleaning object-semiconductor test board into the dry system.

[0050] Please refer to FIG. 2 , the dry purification system 1 of this embodiment inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com