Process for preparing EDTA disodium salt

A technology of ethylenediaminetetraacetic acid disodium salt and ethylenediamine, applied in the field of preparation of ethylenediaminetetraacetic acid disodium salt, can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

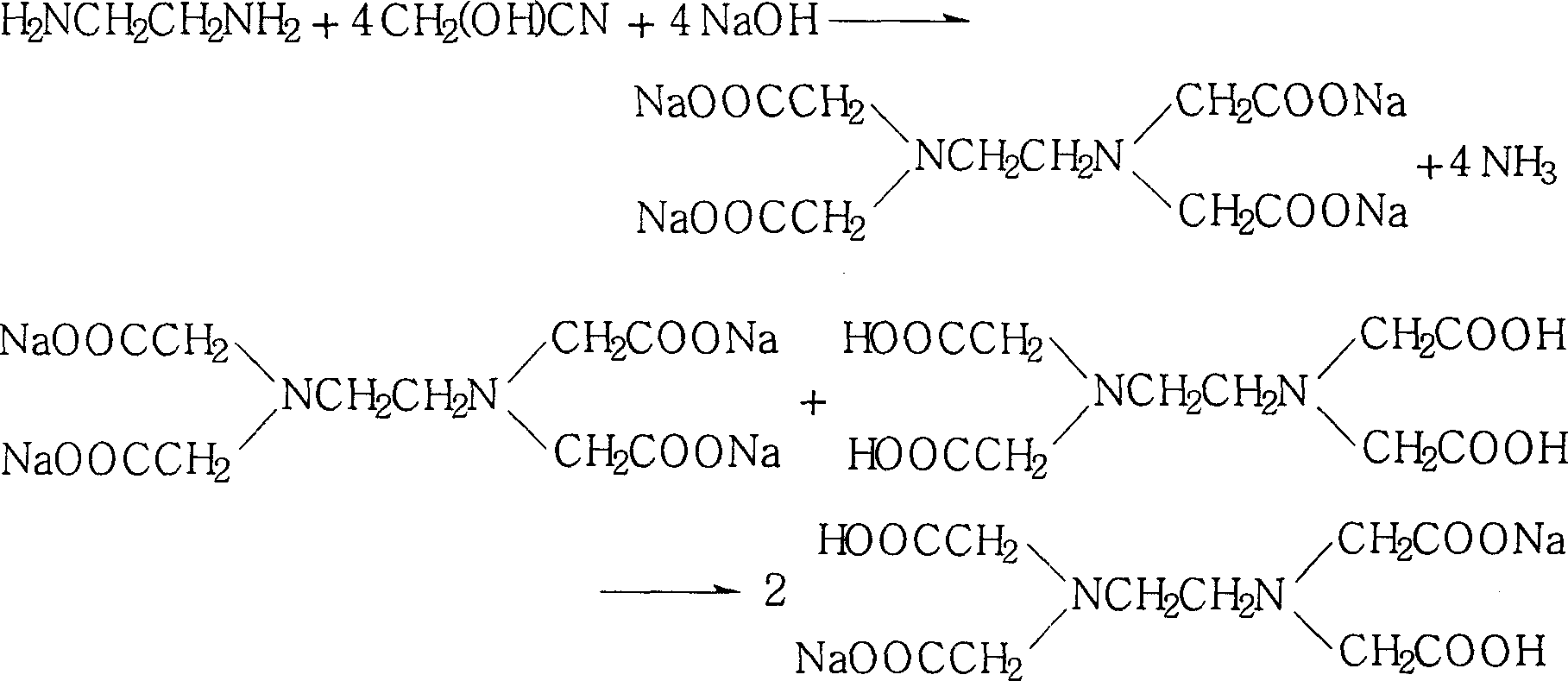

Method used

Image

Examples

Embodiment 1

[0019] Mix 15.1 g of ethylenediamine 99.4% by mass and 173.3 g of sodium hydroxide 30% by mass in a 250ml three-flask of 250 ml with a thermometer, condenser, and stirrer, and heat up at 85°C Within 5 hours, 163 g of hydroxyacetonitrile with a mass percent content of 35% was added dropwise. After the drop was completed, the temperature was raised to 110° C. to react for 30 minutes, and 130 g of water and 0.2 g of hydrogen peroxide were added. Add 75g of EDTA to adjust the pH value of the reaction solution to 5-6. Add activated carbon to the reaction solution for decolorization, add 42g of EDTA to the decolorized reaction solution to adjust the pH value to 3.5-4.5, concentrate, crystallize, separate and dry the reaction solution to obtain 147.5g of white crystalline product of EDTA disodium salt, content 99.3% , Yield 60.5% (calculated as sodium hydroxide). After separating the disodium salt of EDTA, the mother liquor can be acidified with sulfuric acid to obtain EDTA, which i...

Embodiment 2

[0021] Carry out feeding operation by embodiment 1, difference is that the hydroxyacetonitrile charging amount among the example 1 becomes 187.5g, finally obtains the white crystalline product 151g of EDTA disodium salt, content 99.4%, yield 62% (with sodium hydroxide count).

Embodiment 3

[0023] The feeding operation is carried out as in Example 1, the difference is that hydroxyacetonitrile is added dropwise at 85°C, and the temperature is raised slowly at the same time. After the drop is completed within 5 hours, the temperature rises to 110°C, and finally the white crystalline product 152.3 of EDTA disodium salt is obtained. g, content 99.5%, yield 62.6% (calculated as sodium hydroxide).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com