Pulse heat pipe radiator for electronic cooling

A pulsating heat pipe, electronic cooling technology, applied in cooling/ventilation/heating transformation, indirect heat exchangers, electrical solid devices, etc., can solve the problems of increased fan noise, reduced service life, increased fan wear, etc., to improve efficiency. , The effect of stable operation and noiseless operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

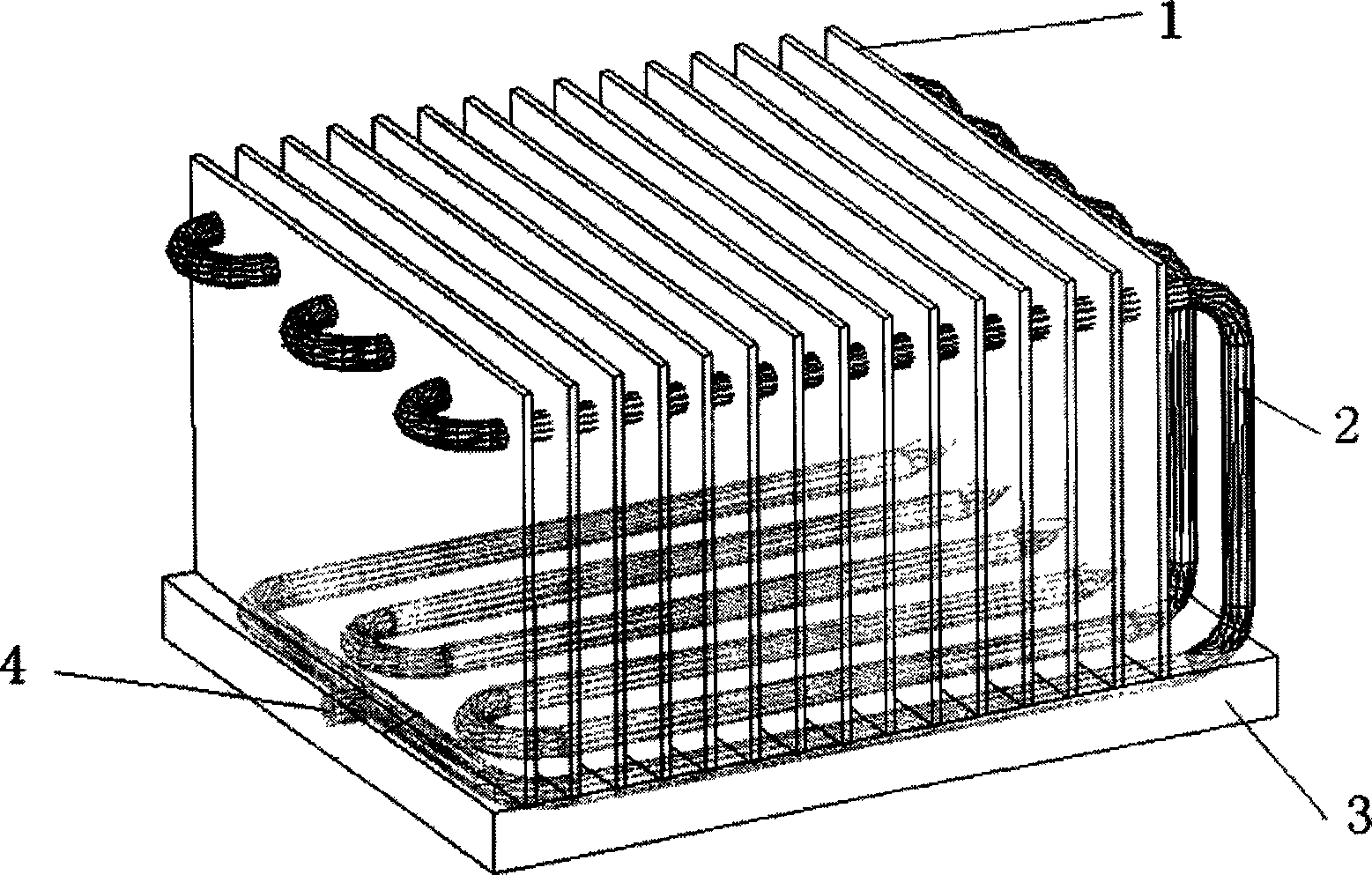

[0010] Referring to FIG. 1 , the present invention includes a cooling fin 1 , a pulsating heat pipe 2 and a cooling seat 3 . A number of stainless steel heat dissipation fins 1 welded longitudinally and parallel to the heat sink 3 on the heat sink 3, grooves are milled on the heat sink 3, and the pulsating heat pipe 2 is a serpentine circuit formed by bending and welding capillary tubes. Fold, the lower part is welded in the groove, as the heating section, and the upper part passes through the through hole of the fin 1, and welded together, as the cooling section. A closed interface 4 is provided on the pulsating heat pipe 2 for vacuuming

[0011] In the production process of the radiator, it is required that the inside of the copper tube of the heat pipe is clean, and there is no gap when the copper tube is welded. The welding and contact between the fin 1, the pulsating heat pipe 2 and the heat sink 3 are required to be tight. 4 After injecting the working medium, ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com