Heat exchanger, method of manufacturing heat exchanger, liquid cooling system, light source device, projector, electronic device unit, and electronic equipment

A technology of heat exchanger and manufacturing method, applied in the cooling of instruments, parts of instruments, cooling/ventilation/heating renovation, etc., can solve problems such as electrolytic corrosion, reduced thermal conductivity, blocked flow paths, etc., and achieve good diffusion bonding , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the heat exchanger, the manufacturing method of the heat exchanger, the liquid cooling system, the light source device, the projector, the electronic device unit, and the electronic equipment of the present invention will be described with reference to the accompanying drawings.

[0041] 〔Heat exchanger〕

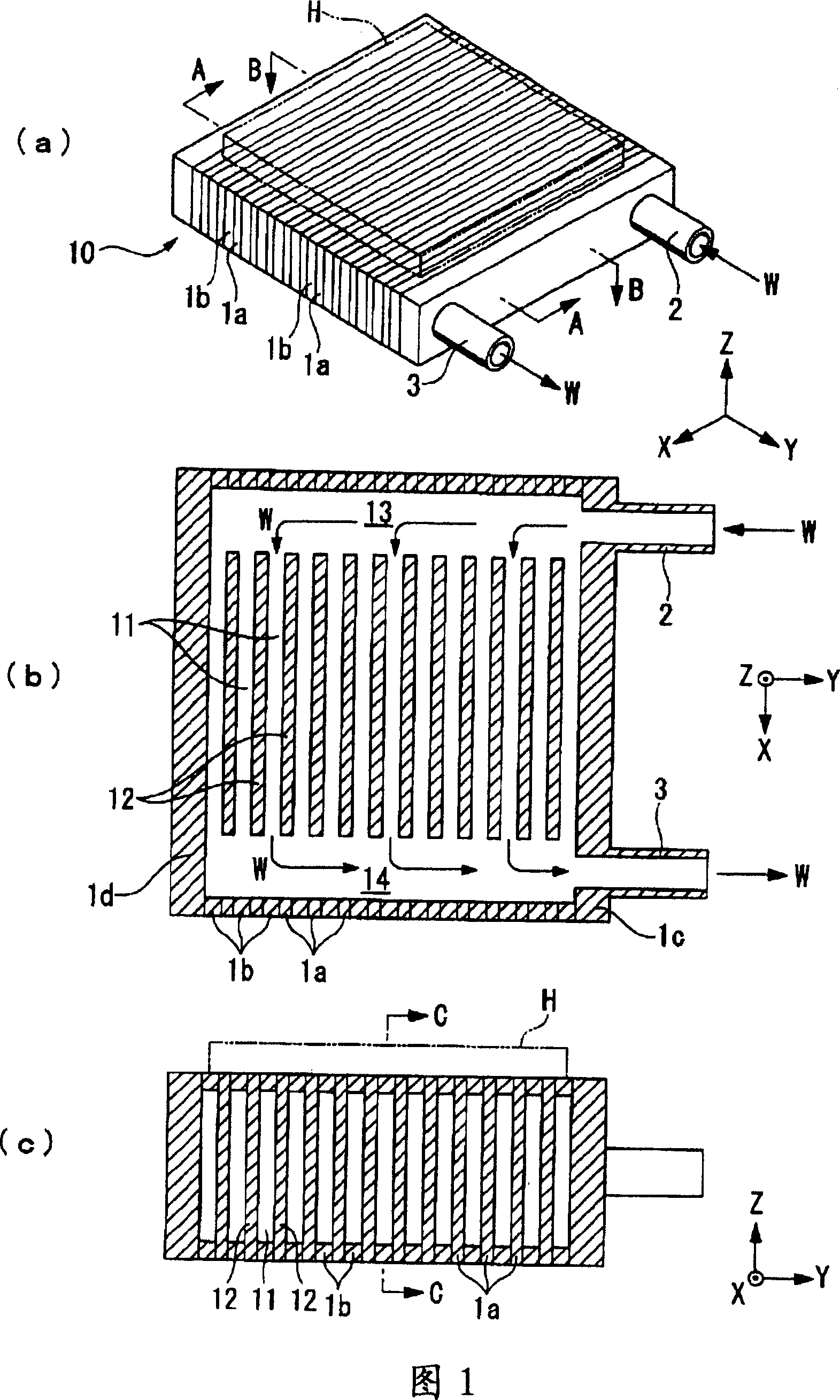

[0042] Fig. 1 is a diagram showing a schematic configuration of a heat exchanger, Fig. 1(a) is a perspective view, Fig. 1(b) is a longitudinal sectional view, and Fig. 1(c) is a transverse sectional view.

[0043] The heat exchanger 10 is a plate-shaped member formed by laminating a plurality of metal thin plates (laminated plates 1a, 1b, etc.) with high thermal conductivity such as copper or aluminum, and has a plurality of liquids such as water W inside it. The fine flow path 11.

[0044] As shown in FIG. 1( a ), on the side of the heat exchanger 10 , an introduction pipe 2 for introducing water W into the inside, and an outlet pipe 3 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com