Technological method of improving small particle product strength and elliminating product dust

A process method and small particle technology, applied in the direction of fertilizer form, application, nitrogen fertilizer, etc., can solve the problems of broken dust, easy agglomeration, small particles, etc., to increase particle size and strength, improve product properties, and reduce granulation load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

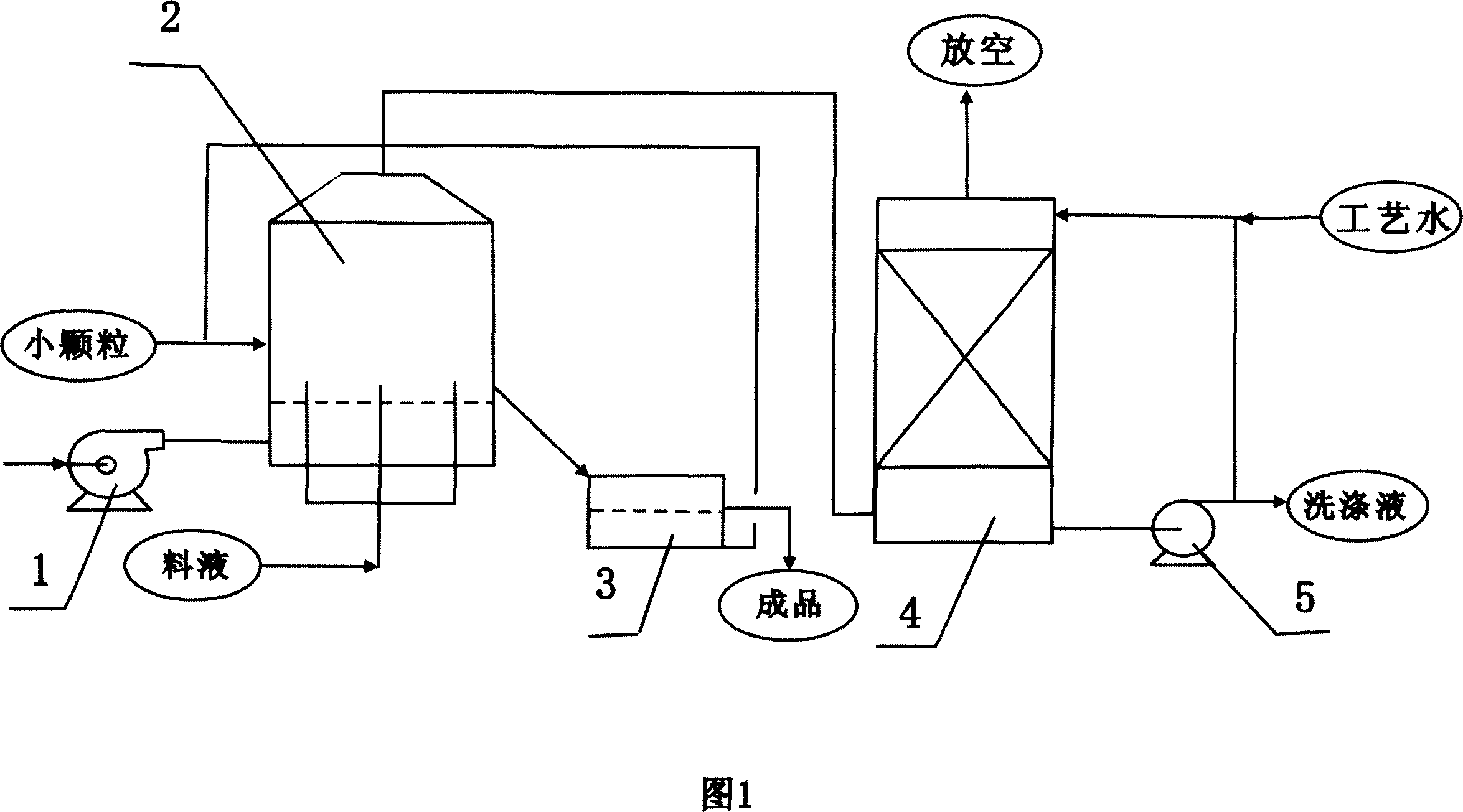

Image

Examples

Embodiment 1

[0031] A. Small particles with a particle size of 0.85~2.8mm from the urea prilling tower enter the fluidized bed through a belt, and the bed temperature is controlled at 110°C through the fluidized air, and 98.5% of the urea melt from the evaporation system of the urea unit is introduced into the fluidized bed , The particles are continuously coated after being atomized by the nozzle. The weight ratio of seed crystal to urea melt is controlled at 1;

[0032] B. Small particles with a particle size of 0.85~2.8mm from the urea prilling tower enter the fluidized bed through a belt, and the bed temperature is controlled at 110°C through fluidized air. 90% of the urea melt from the evaporation system of the urea unit is introduced into the fluidized bed. In the bed, the particles are continuously coated after being atomized by the nozzle, and the ratio of the seed crystal to the urea melt is controlled at 1.2 or 0.6.

[0033] Item

Embodiment 2

[0035] A. Small particles with a particle size of 1.0~2.5mm out of the ammonium nitrate prilling tower enter the fluidized bed through a belt, and the bed temperature is controlled at 115°C through fluidized air. The 98% ammonium nitrate solution from the evaporation system of the ammonium nitrate unit is introduced into the stream. In the fluidized bed, the particles are continuously coated after atomization by the nozzle, and the weight ratio of the seed crystal to the ammonium nitrate solution is controlled at 1.5 or 1.2;

[0036] B. Small particles with a particle size of 1.0~2.5mm out of the ammonium nitrate prilling tower enter the fluidized bed through a belt, and the bed temperature is controlled at 115°C through fluidized air. The 85% ammonium nitrate solution is introduced into the stream from the evaporation system of the ammonium nitrate device. In the fluidized bed, the particles are continuously coated after atomization by the nozzle, and the weight ratio of the seed...

Embodiment 3

[0039] Using this process, low-nitrogen compound fertilizer can be supplemented with nitrogen to increase the nitrogen content, and the nitrogen (N) phosphorus (P) from the compound fertilizer device 2 O 5 ) Potassium (K 2O) The low-nitrogen compound fertilizer with a ratio of 12-18-15 enters the fluidized bed granulator in the form of seed crystals, and the bed temperature is controlled at 110 ℃ through fluidized air, and 95% of the urea solution from the evaporation system of the urea unit is introduced In the fluidized bed, the particles are continuously coated after atomization by the nozzle, and the weight ratio of the seed crystal to the urea solution is controlled at 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com