Reflecting type whole solid paper loading electrochromism device and preparation method thereof

An electrochromic device, electrochromic layer technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of image blur, pixel display leakage, dispersion, etc., achieve low cost, improve contrast, overcome crosstalk phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

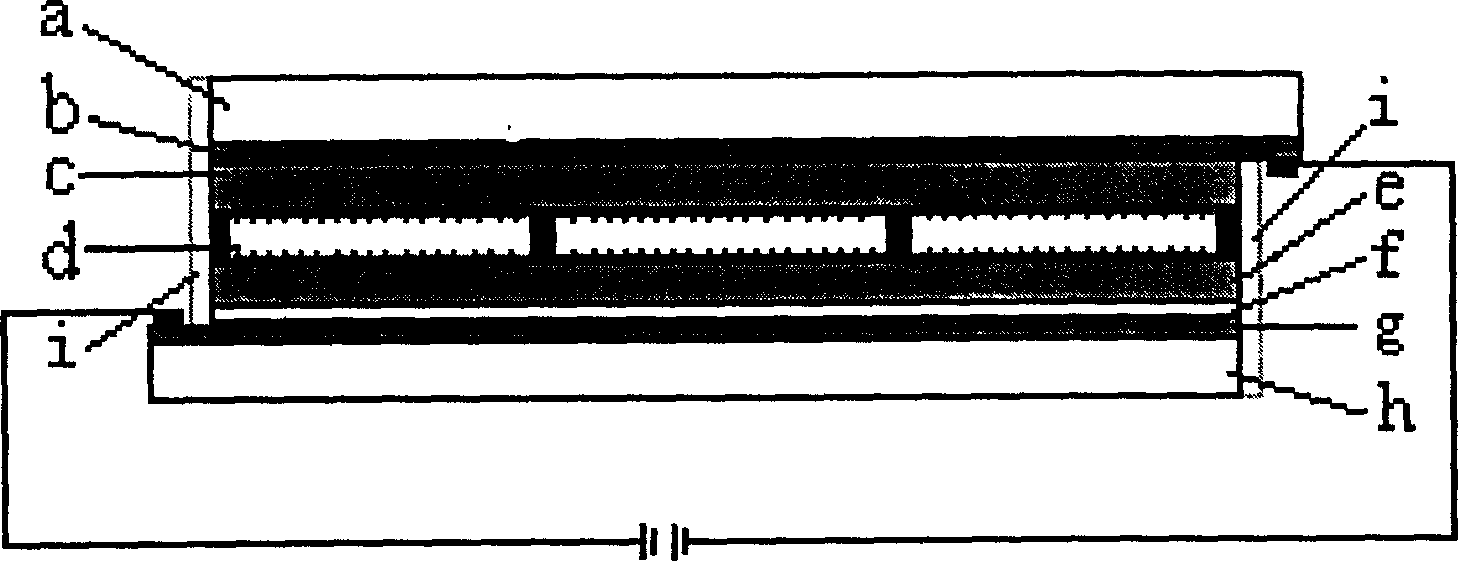

[0024] Viologen derivatives 1-ethyl-1'-(4-(4'-vinyl)benzyl)-4,4'-bipyridyl iodide chloride quaternary with styrene, acrylic acid, butyl acrylate Copolymer, ethanol, polyvinylpyrrolidone (PVP) are formulated into a suspension, evenly coated on both sides of ordinary white paper cut to match the size of the ITO conductive glass substrate, and baked under vacuum to remove the solvent to obtain Paper-borne electrochromic layer d. Place the prepared PEO derivative-PMMA-LiClO on the electrode side of a piece of ITO conductive glass ab 4 Gel type polyelectrolyte ion conductor layer c. On the electrode side of another ITO conductive glass gh, use magnetron sputtering to make a NiO ion storage layer f, and then place the PEO derivative-PMMA-LiClO 4 Gel type polyelectrolyte ion conductor layer e. Place the paper-supported electrochromic layer d between the two ion conductor layers c and e, and press them tightly. Finally, the side surface of the obtained (abcdefgh) layer is sealed a...

Embodiment 2

[0026] The viologen polycondensate, acetonitrile, and polyvinylpyrrolidone (PVP) prepared by condensation of viologen derivative 4,4′-bipyridine and chloroethyl chloroacetate was prepared into a suspension, and evenly coated on the cut-out and ITO The two sides of the ordinary white paper whose size is matched to the conductive glass substrate are baked under vacuum to remove the solvent, forming the paper-borne electrochromic layer d. Place the prepared PEU derivative-LiClO on the electrode side of a piece of ITO conductive glass ab 4 Gel type polyelectrolyte ion conductor layer c. On the electrode side of another ITO conductive glass gh, TiO was fabricated by sol-gel spin coating method 2 Ion storage layer f, and then placed on the PEU derivative-LiClO 4 Gel type polyelectrolyte ion conductor layer e. Place the paper-supported electrochromic layer d between the two ion conductor layers c and e, and press them tightly. Finally, the side surface of the obtained (abcdefgh) ...

Embodiment 3

[0028] Viologen derivative bromide 1-phosphonic acid ethyl 1′-ethyl-4,4′-bipyridyl, acetonitrile, polyvinylpyrrolidone (PVP) prepared into a suspension, evenly coated on the cut into The two sides of ordinary white paper matching the size of the ITO conductive glass substrate are baked under vacuum to remove the solvent, forming the paper-borne electrochromic layer d. Place the prepared epichlorohydrin-dichloromethane-PEO-LiClO in the presence of KOH on the electrode side of a piece of ITO conductive glass ab 4 Gel type polyelectrolyte ion conductor layer c. On the electrode side of another ITO conductive glass gh, the polyaniline ion storage layer f made by electropolymerization is placed, and the -PEO-LiClO treated with epichlorohydrin-dichloromethane in the presence of KOH is placed. 4 Gel type polyelectrolyte ion conductor layer e. Place the paper-supported electrochromic layer d between the two ion conductor layers c and e, and press them tightly. Finally, the side sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com