Method for making vertical double diffusion FET compatible conventional FET

A vertical double-diffusion, FET technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the control chip has a reduced ability to monitor overheating of the output chip, increased circuit reliability, and increased packaging costs. and other problems, to achieve the effect of solving reliability degradation, realizing high voltage and high current control, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

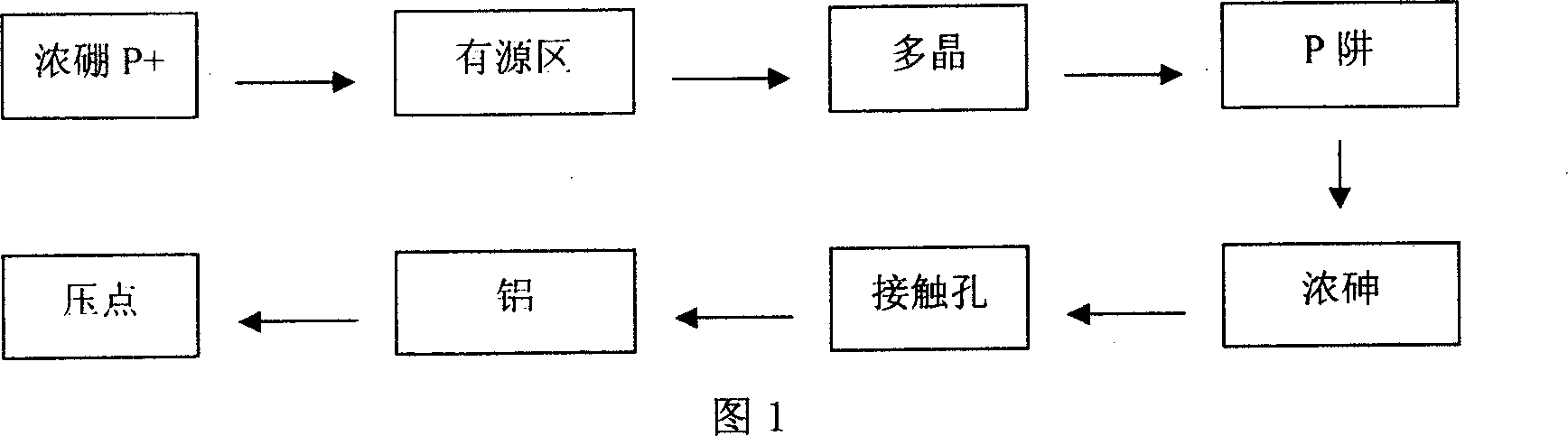

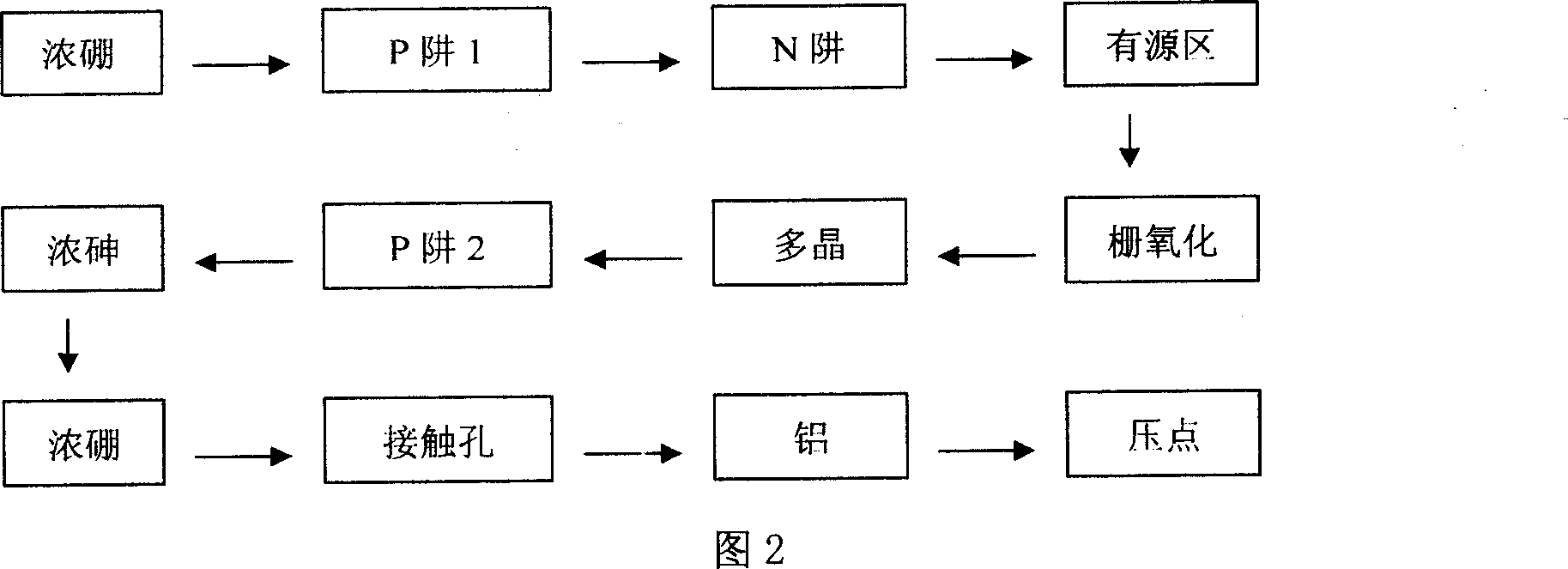

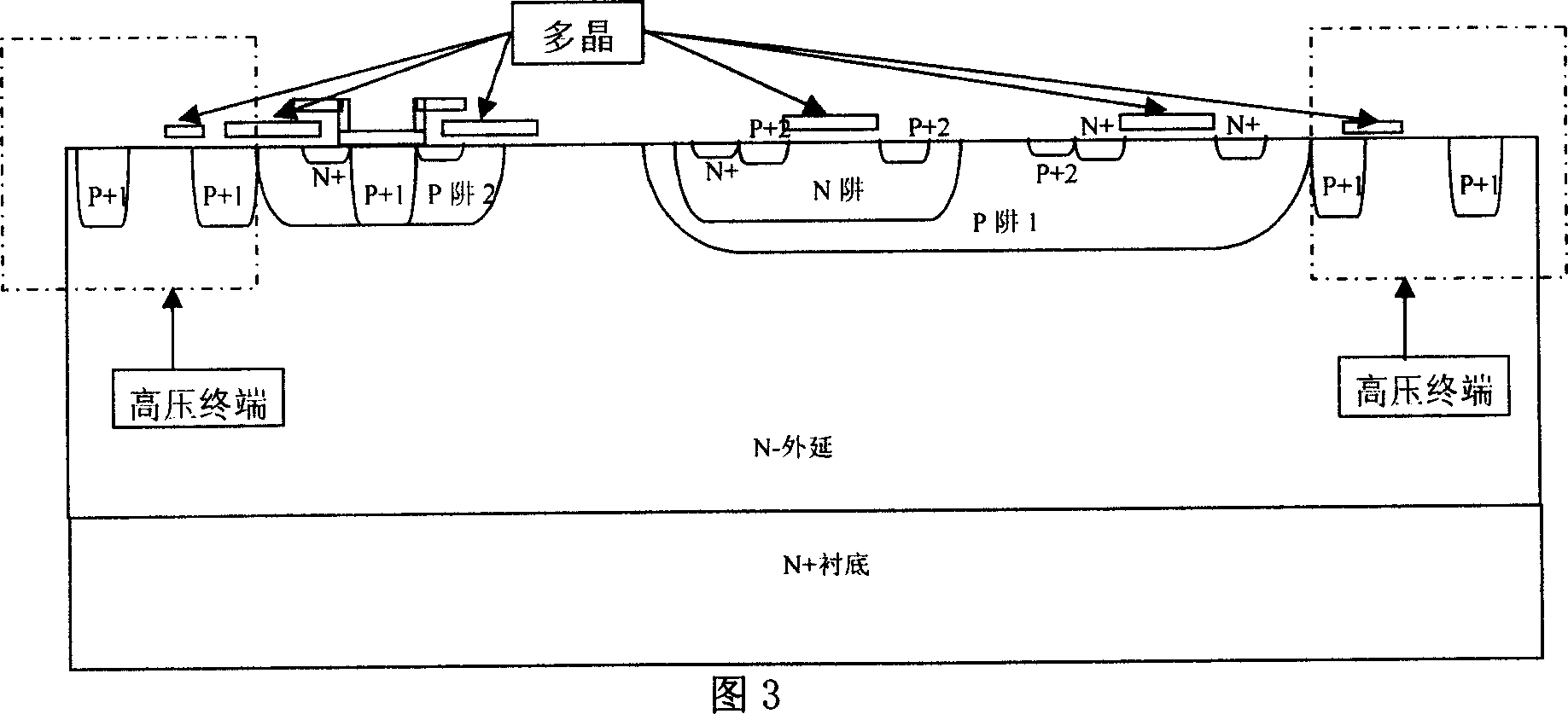

[0037] Under this platform, we realized the integration of control circuit and output high voltage VDMOS on the chip area of 2000*2200μm. The specific implementation is as follows:

[0038] 1.) High-concentration P+ implantation, pushing junction depth: The concentration and junction depth here have a great impact on the withstand voltage of the entire die. The specific concentration and junction depth should be adjusted appropriately according to the corresponding layout design.

[0039] 2.) Inject PWELL1 in the low-pressure area, and pre-push the junction depth: here is only a pre-push junction depth, and the junction depth should not be pushed too deep. Because there are still many high-temperature processes behind, the junction will be further deepened.

[0040] 3.) NWELL implantation in low-voltage area, pre-push junction depth: PWELL and NWELL for low-voltage CMOS are added before ACTIVE (active area). The junction depth of PWELL and NWELL here should not be pushed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com