Method and apparatus for photochemical degradation of organic gas

An organic matter and photochemical technology, applied in the field of photochemical technology to degrade organic matter gas, can solve the problems of complex equipment structure, large equipment investment, high operating cost, etc., and achieve the effect of convenient manufacturing and installation, high safety, and improving purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

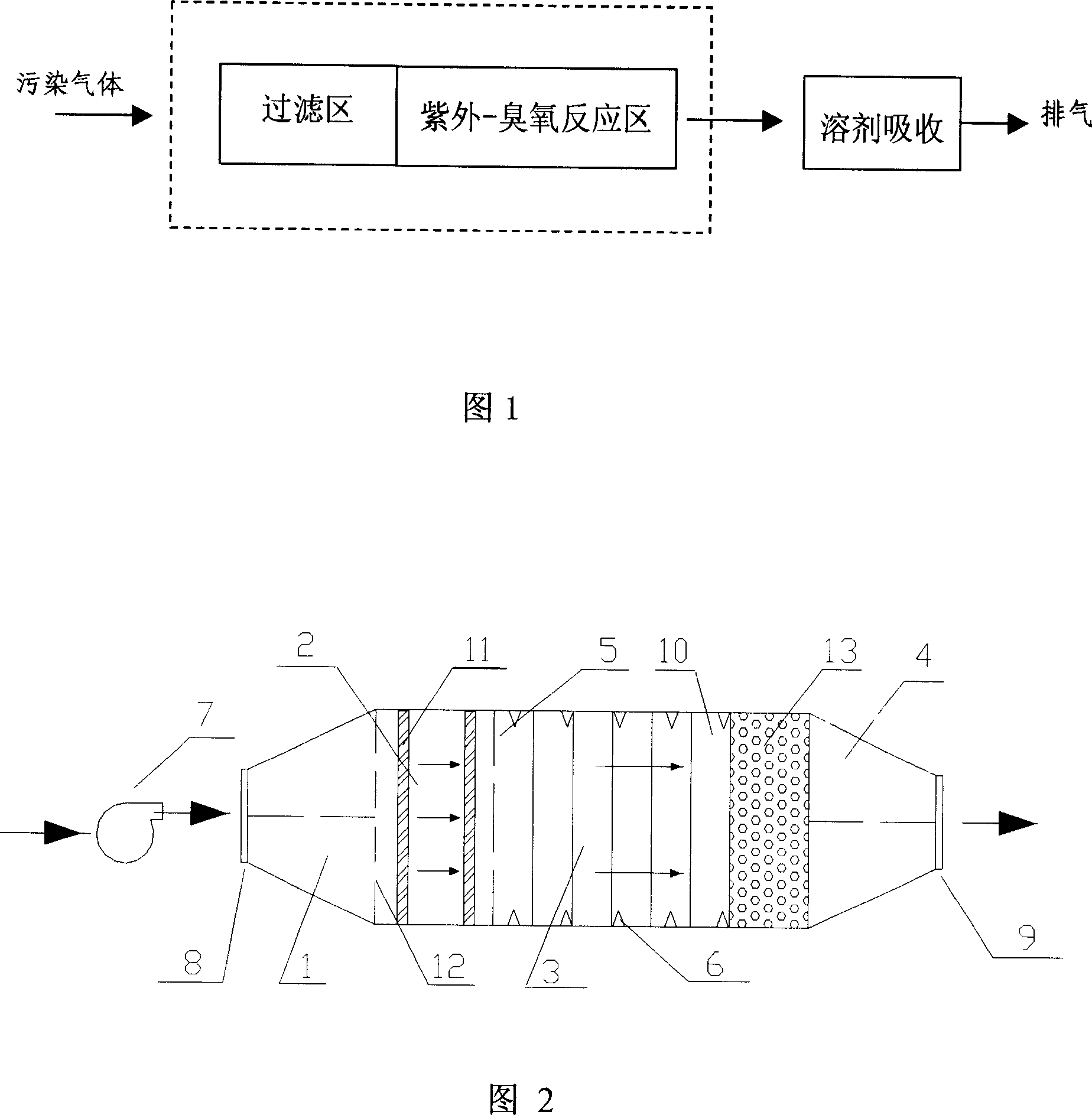

[0029] The main body of the device for photochemically degrading organic matter gas as shown in Figure 2 is a cylindrical or prismatic container, and the container is divided into a filter area and an ultraviolet-ozone reaction area 3 by a partition, and the tail gas is regulated after being purified by a solvent-based absorption device 13. The tail gas is discharged from the outlet 9, and the waste water after absorbing the tail gas is sent to the sewage treatment plant for unified treatment.

[0030] The container is divided into five functional areas: an air intake adjustment area 1, a filter area 2, an ultraviolet-ozone reaction area 3, a solvent-based absorption device 13, and an air outlet adjustment area 4. The ultraviolet lamp 10 is fixed in the ultraviolet-ozone reaction area 2.

[0031] The front part of the filter area 2 is provided with an air intake adjustment grille 12 to separate the air intake adjustment area 1 from the filter area 2, and the air intake adjustme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com