A kaolin based compound molecule sieve and preparation method thereof

A technology of composite molecular sieve and kaolin, applied in molecular sieve catalysts, chemical instruments and methods, organic chemistry, etc., to achieve the effects of improving shape-selective catalytic performance, improving product distribution, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

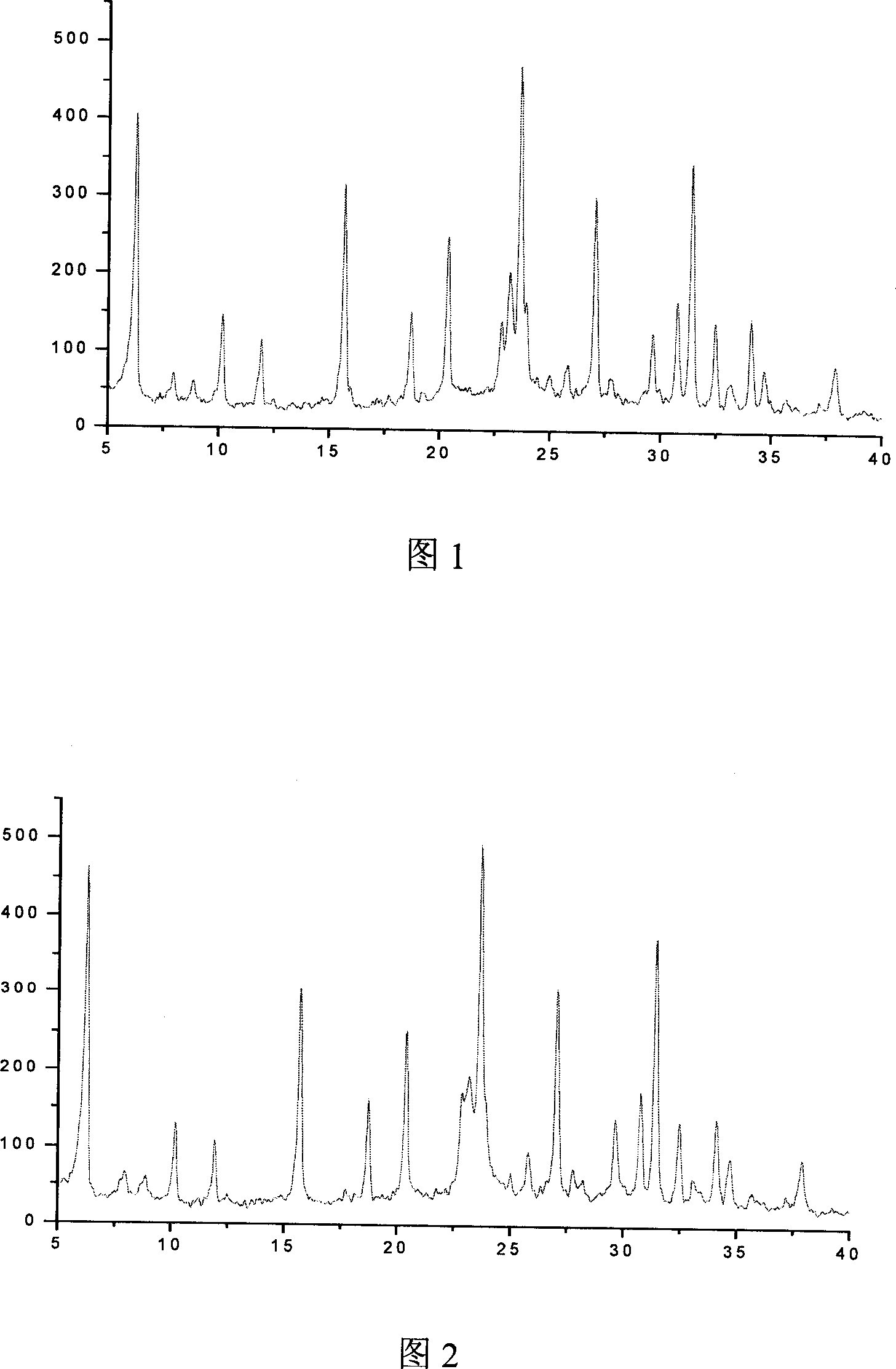

Embodiment 1

[0066] The directing agent is prepared by the method for preparing NaY directing agent proposed in US Pat. No. 3,639,009 and US 3,671,191. The specific ratio is as follows: 15SiO 2 : Al 2 o 3 : 16Na 2 O: 320H 2 O (molar ratio).

[0067] Dilute 15.60 grams of water glass with 21.70 grams of deionized water, then add 1.31 grams of 50w% (w% refers to weight percentage, the same below) aqueous solution of aluminum sulfate octadecadecanoate successively under stirring, 8.0 grams of the above-mentioned directing agent, and 850 After roasting for 5 hours at ℃, 3.33 grams of kaolin microspheres were processed, stirred for 10 minutes, put into a 100 ml polytetrafluoroethylene-lined reactor, and crystallized at 100 ℃ for 24 hours; after cooling, add 0.65 tetraethylammonium bromide and 1.02 grams of tetrabutylammonium bromide, stirred for 10 minutes, then adjusted the pH value of the mixed slurry to 10.15 with 30w% phosphoric acid solution, stirred for 10 minutes and continued cryst...

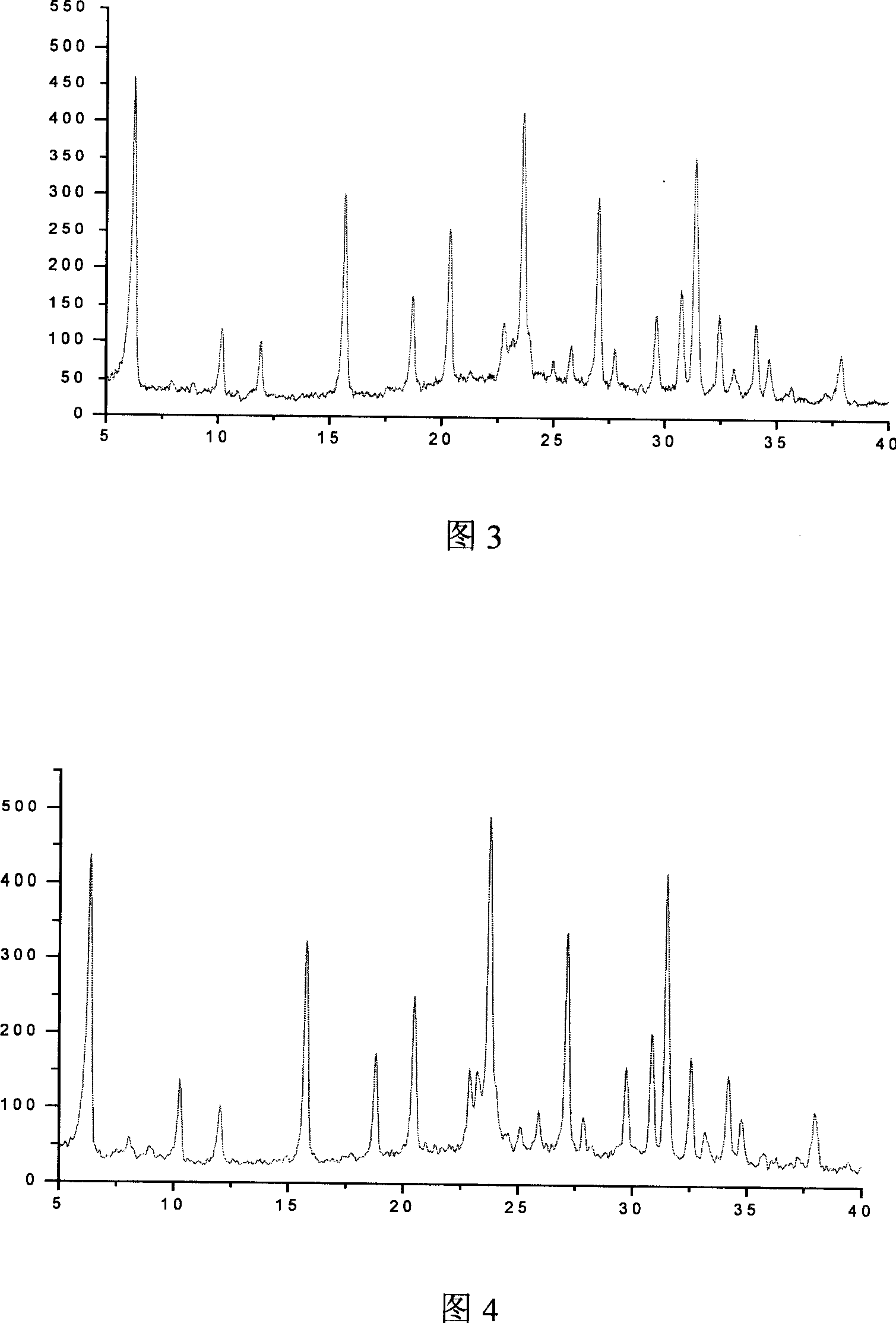

Embodiment 2

[0069] Dilute 15.60 grams of water glass with 22.27 grams of deionized water, then add 8.0 grams of directing agent in Example 1 successively under stirring, 3.73 g of kaolin after roasting at 850 ° C for 6 hours, 0.64 g of sulfuric acid of 25.44w%, and stir After 10 minutes, put it into a 100ml polytetrafluoroethylene-lined reactor and crystallize at 100°C for 24 hours; after cooling, add 0.65 grams of tetraethylammonium bromide and 1.02 grams of tetrabutylammonium bromide, and stir for 10 minutes , and then use phosphoric acid solution to adjust the pH value of the mixed slurry to 10.10, stir for 10 minutes and continue crystallization at 165° C. for 24 hours. After the reaction, the product is filtered, washed and dried to obtain the material of the present invention. The XRD analysis of this material (as shown in Figure 2) shows that it has both ZSM-5 characteristic peaks and NaY characteristic peaks, indicating that it is a composite molecular sieve material.

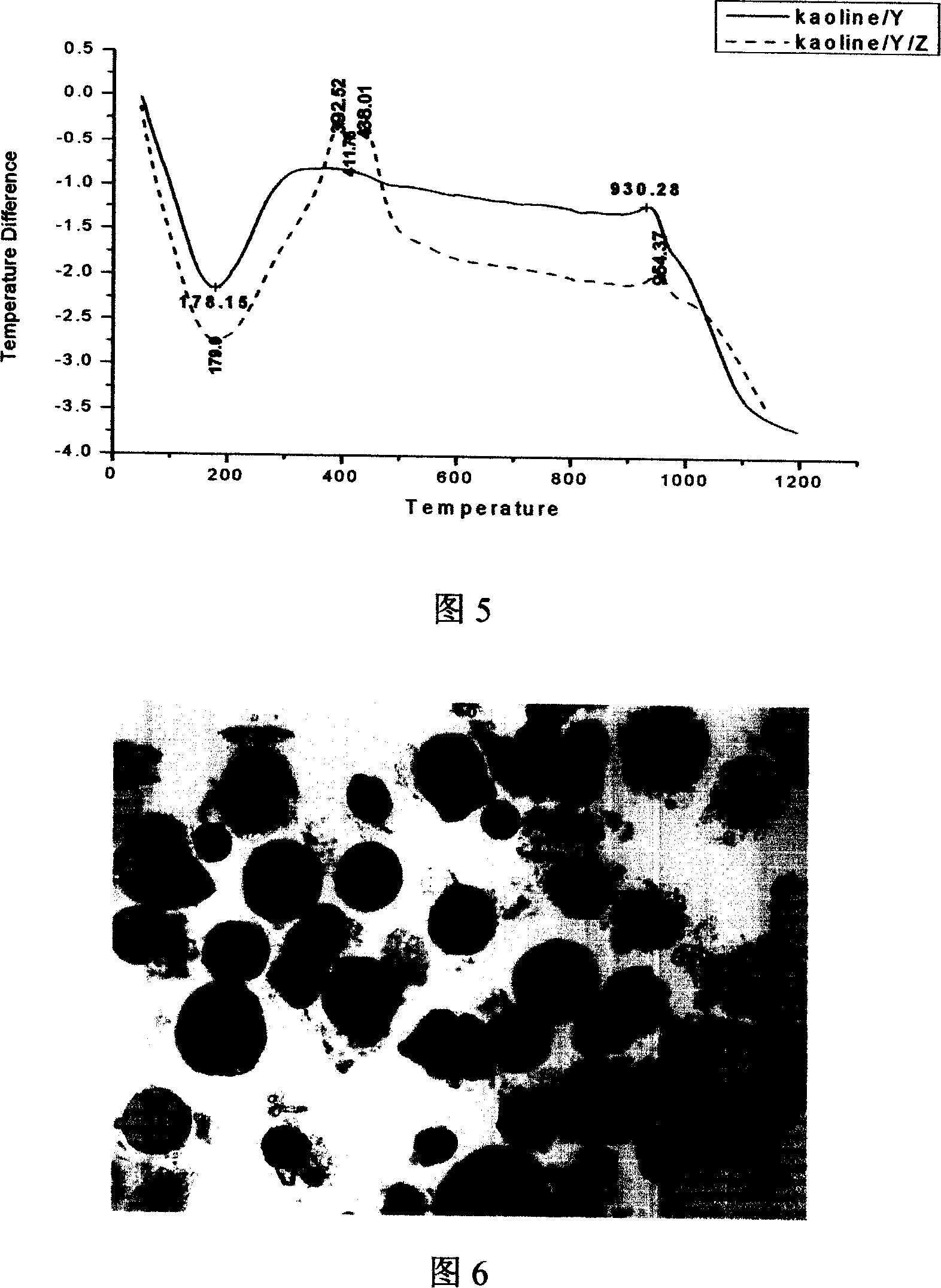

Embodiment 3

[0071] 12.40 grams of water glass was diluted with 26.22 grams of deionized water, and then under stirring, 3.22 grams of kaolin microspheres (B) and 2.61 grams of 50w% aluminum sulfate octadecahydrate aqueous solution were added successively at 980 ° C for 3 hours. 8.0 grams of directing agent, 2.94 grams of kaolin microspheres (A) after being roasted at 660°C for 4 hours, stirred for 10 minutes and then put into a 100 ml lined polytetrafluoroethylene reactor for crystallization at 100°C for 24 hours; after cooling, Add 0.65 grams of tetraethylammonium bromide and 1.02 grams of tetrabutylammonium bromide, stir for 10 minutes, then use phosphoric acid solution to adjust the pH value of the mixed slurry to 10.18, stir for 10 minutes and continue crystallization at 140 ° C for 15 hours, and then Continue crystallization at 170°C for 8 hours. After the reaction, the product was filtered, washed, and dried. XRD (as shown in FIG. 3 ) showed that the obtained material had both NaY c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com