Laminar crystallized copper powder and preparation method thereof

A technology of flake crystal and copper powder, which is applied in the field of flake crystal copper powder and its preparation, can solve the problems of non-compliance with environmental protection requirements and poor repeatability, and achieve the effect of smooth surface, simple preparation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

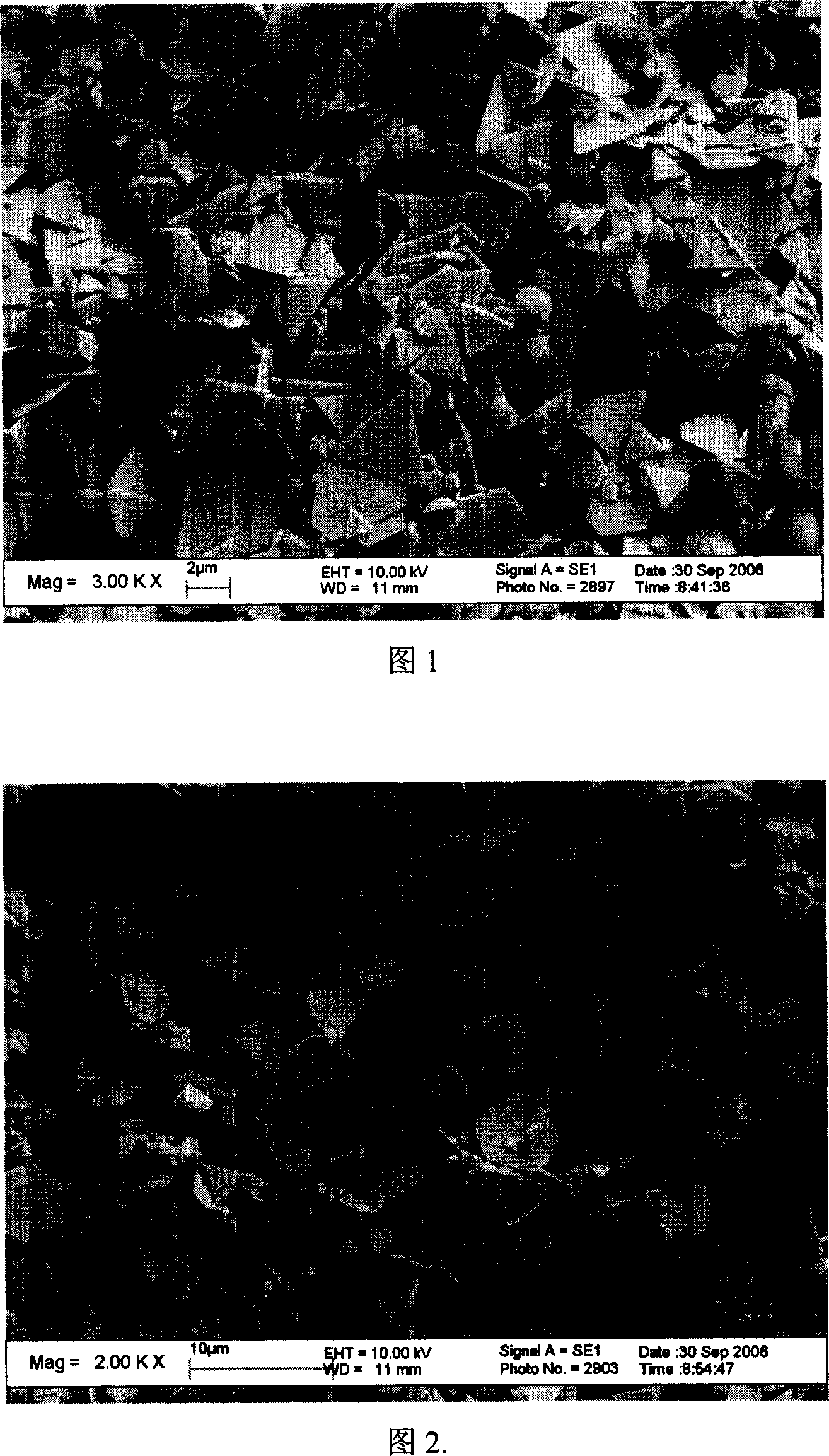

[0023] Dissolve 0.25 g of gum arabic in 70 ml of deionized water, add 3.6 g of cuprous bromide, stir and disperse evenly, heat up to 50°C, and then add 1.0 ml of 28% ammonia water. Dissolve 4.8g of ascorbic acid in 30ml of water and heat to 50°C. This reducing solution was added to the above cuprous bromide dispersion. After reacting for 0.5 hours, an aqueous ammonia solution (3 ml of ammonia water mixed with 17 ml of deionized water) was added dropwise. After reacting for 3 hours, the copper powder was centrifuged, washed repeatedly with deionized water and then with ethanol, and finally vacuum-dried at 40°C. Observation of the prepared copper powder with a scanning electron microscope, the results are shown in Figure 1. It can be seen that most of the copper powder is flake-like particles, in the shape of triangular or hexagonal flakes, with a diameter distribution of 1-5 μm and a thickness of 0.1 μm. ~0.2μm, particle aspect ratio between 10~30.

Embodiment 2

[0025] Dissolve 0.25 g of gum arabic in 70 ml of deionized water, add 3.6 g of cuprous bromide, stir and disperse evenly, heat up to 50°C, and then add 2.0 ml of 28% ammonia water. Dissolve 4.8g of ascorbic acid in 30ml of water and heat to 50°C. This reducing solution was added to the above cuprous bromide dispersion. After reacting for 0.5 hours, an aqueous ammonia solution (2 ml of ammonia water mixed with 18 ml of deionized water) was added dropwise. After reacting for 3 hours, the copper powder was centrifuged, washed repeatedly with deionized water and then with ethanol, and finally vacuum-dried at 40°C. Observation of the prepared copper powder by scanning electron microscope shows that most of the copper powder is flaky particles in the shape of triangular or hexagonal flakes with a diameter distribution of 0.5-2.5 μm and a very thin thickness.

Embodiment 3

[0027] Dissolve 0.25 g of gum arabic in 70 ml of deionized water, add 3.6 g of cuprous bromide, stir to disperse evenly, and heat up to 50°C. Dissolve 4.8g of ascorbic acid in 30ml of water, heat to 50°C, and add this reducing solution to the above cuprous bromide dispersion. After reacting for 0.5 hours, an aqueous ammonia solution (4 ml of ammonia water mixed with 16 ml of deionized water) was added dropwise. After reacting for 3 hours, the copper powder was centrifuged, washed repeatedly with deionized water and then with ethanol, and finally vacuum-dried at 40°C. Observing the prepared copper powder with a scanning electron microscope, it can be seen that most of the copper powder is flaky particles, and the particle size is polarized, with a small amount of large particles, with a diameter distribution of 2.0-3.5 μm and a thickness of 0.2-0.5; The particle diameter is 0.5-1.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com