Gas phase self-assembled growth silicon quantum torus nano structure preparation method

A nanostructure and self-assembly technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of expensive equipment, complicated operation of MBE method, etc., and achieve convenient and cost-effective preparation and operation process. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

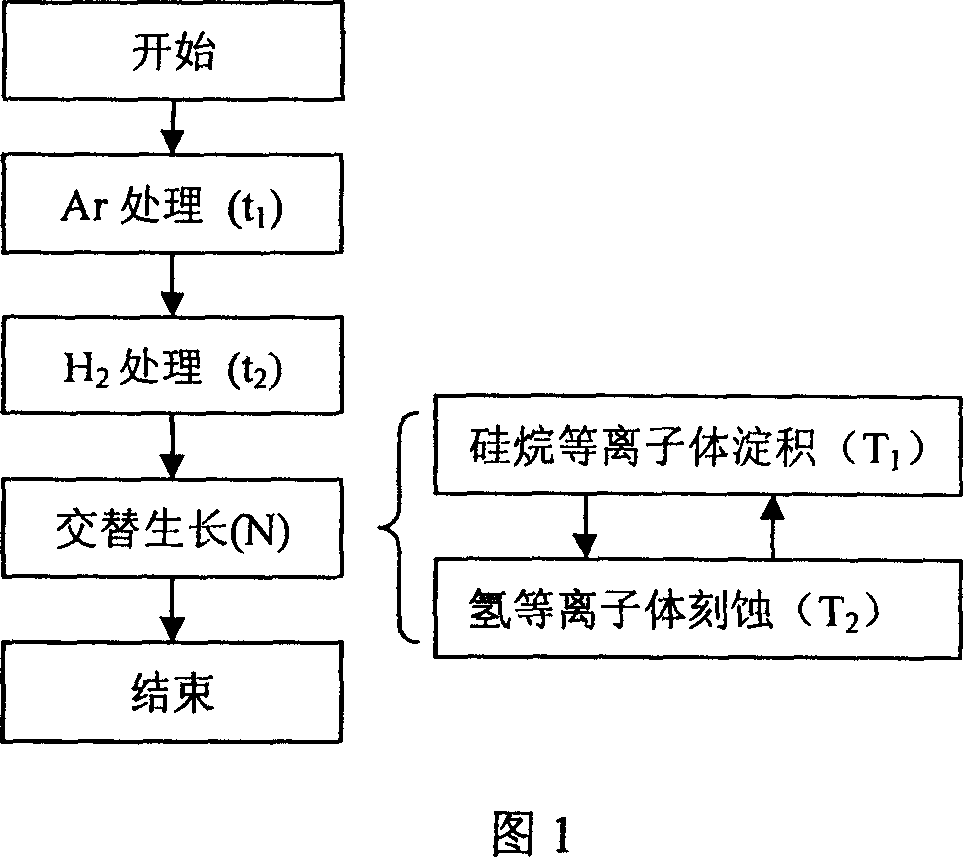

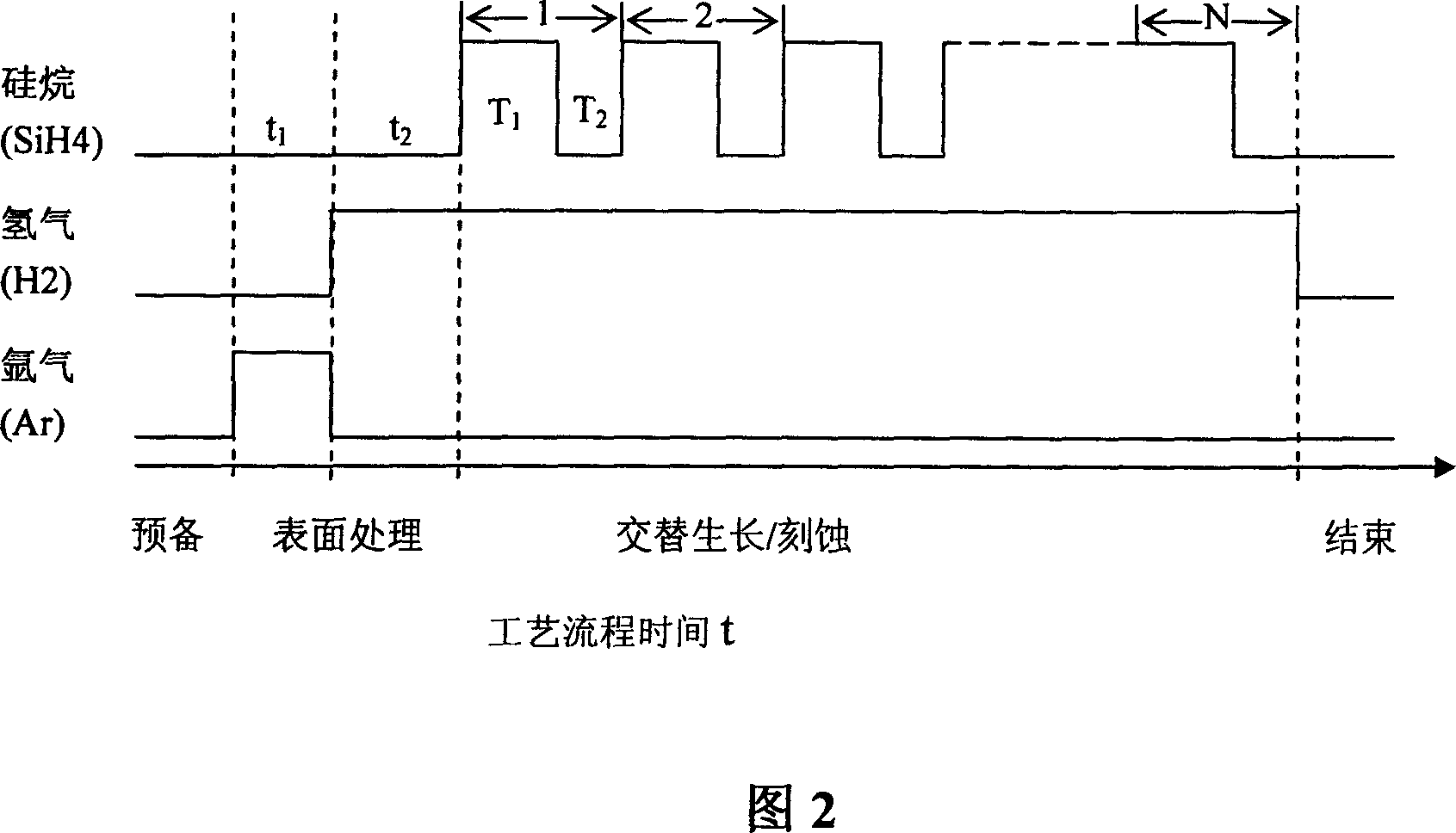

[0026] According to Figures 1 and 2; the first step: pretreatment of the silicon substrate surface:

[0027] Parameters for surface pretreatment with argon and hydrogen plasma:

[0028] First, argon plasma was first used in plasma enhanced chemical vapor deposition (PECVD) systems

[0029] Surface treatment, the specific process conditions are as follows:

[0030] Power source frequency: 13.56MHz, power density: 1W / cm 2

[0031] Reaction chamber pressure: 45Pa, substrate temperature: 200°C

[0032] Processing time: about 300 seconds

[0033] Secondly, hydrogen plasma is used to treat the surface in a plasma-enhanced chemical vapor deposition (PECVD) system, and the specific process conditions are as follows:

[0034] Power source frequency: 13.56MHz, power density: 1.33W / cm 2

[0035] Reaction chamber pressure: 80Pa, substrate temperature: 200°C

[0036] Processing time: 130 seconds

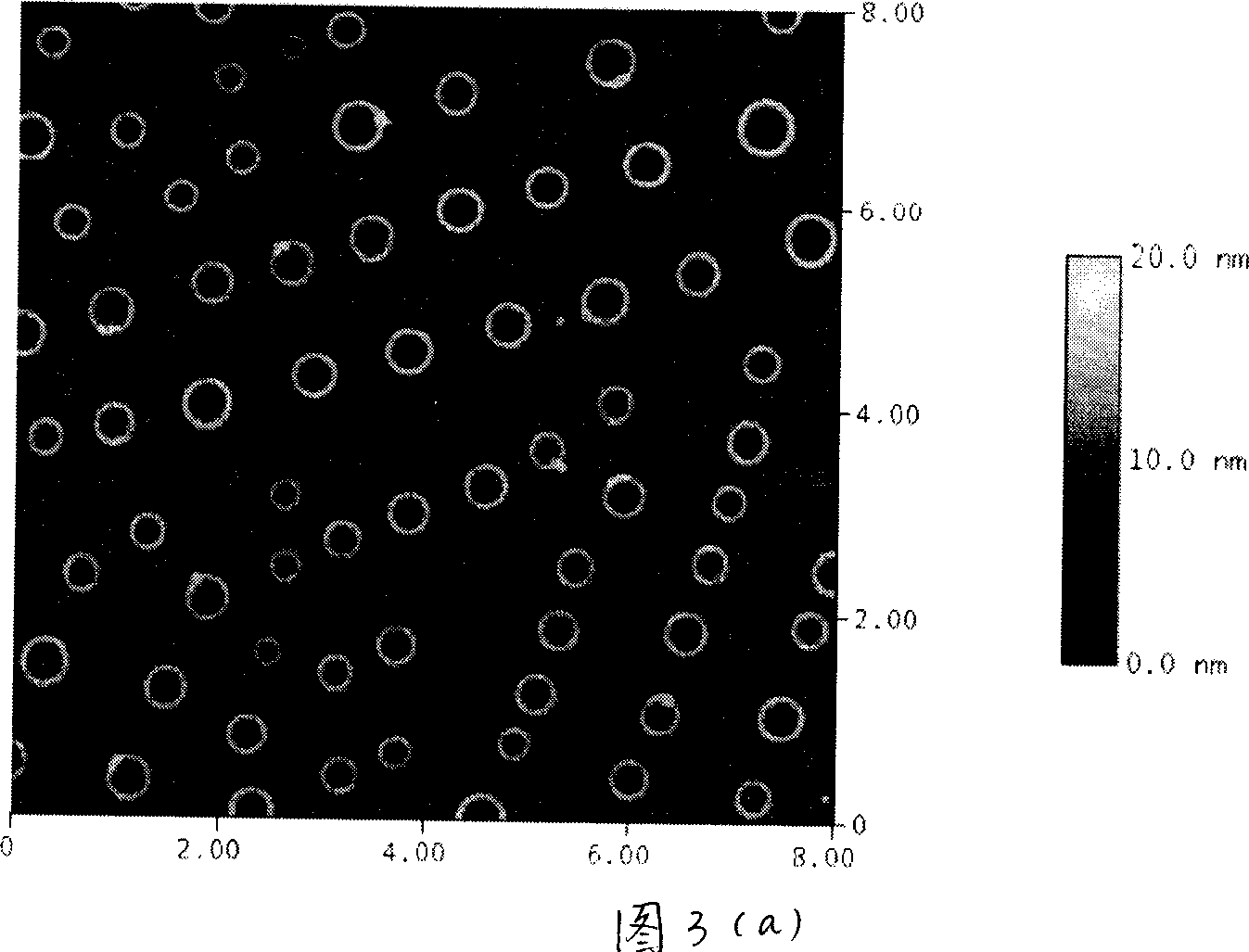

[0037] The second step: use the periodic growth / etching method to grow the Si nanori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com