Polyoxometallate catalyst for preparing biological diesel oil

A polyoxometalate, biodiesel technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, biofuels, etc., can solve the separation of catalyst products and is not suitable for continuous production , easy deactivation and other problems, to overcome the complex process flow, wide applicability of raw materials, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

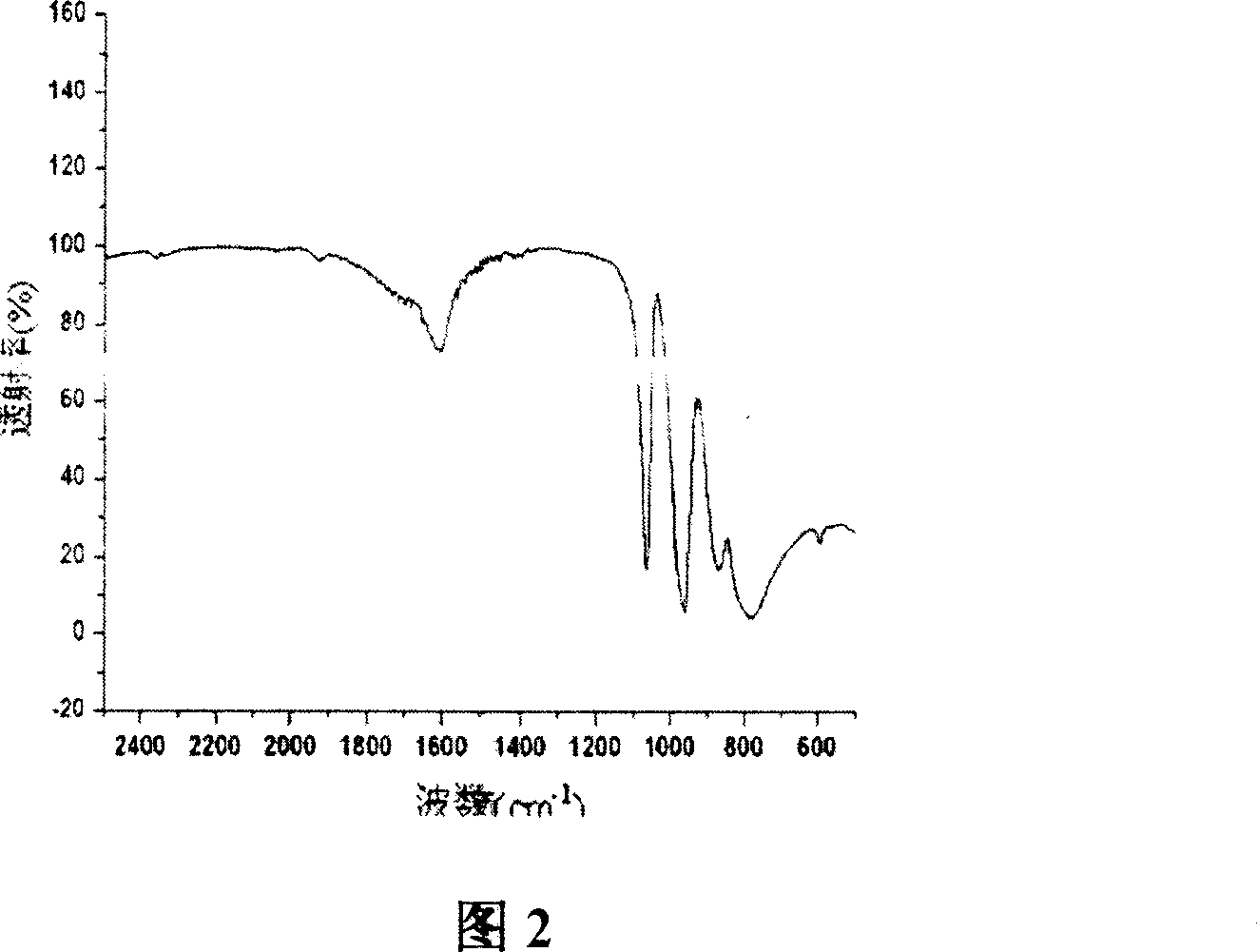

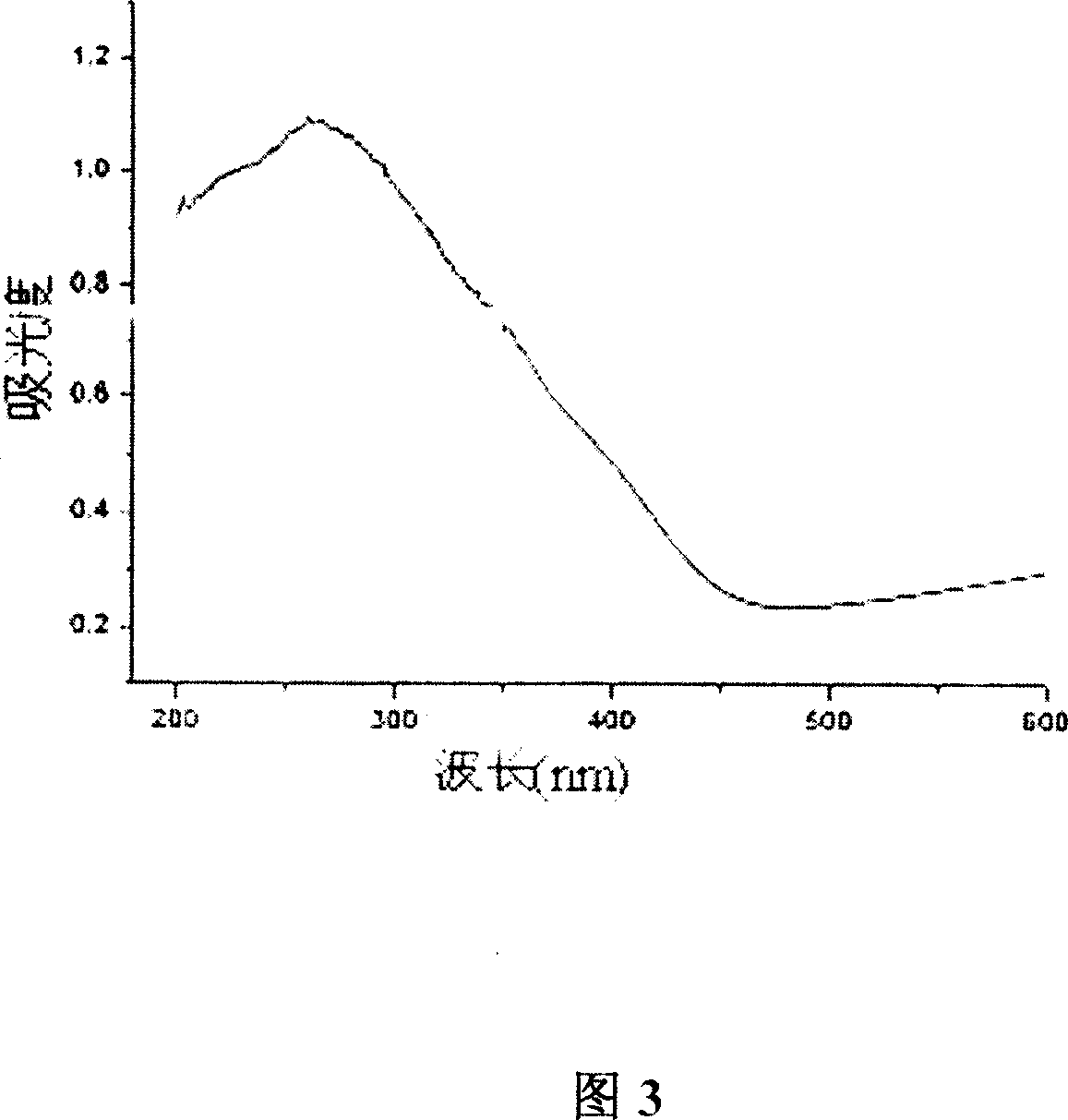

[0072] Weigh the polyoxometalate compound H with a molar ratio of 1:1.5 4 [SiW 12 o 40 ]·23H 2 O and precipitant CsCl. Pour the polyoxometalate compound into the reactor, add distilled water with a mass ratio of 1:5 times, heat to 50°C, and stir to dissolve. A precipitant solid was added thereto, and the reaction solution was aged for 10 hours to precipitate a solid, which was filtered and washed with distilled water for 3 times until the pH value of the eluate reached 5. Precipitate in a mug furnace and sinter at 150°C for 2 hours to obtain a solid catalyst of polyoxometalate compound. Its yield was 84%.

[0073] The structure of the solid catalyst was determined by infrared spectroscopy (see Figure 2) and ultraviolet spectroscopy (see Figure 3).

Embodiment 2

[0075] Weigh the polyoxometalate compound H with a molar ratio of 1:6 6 [P 2 W 18 o 62 ]·23H 2 O and precipitant CsCl. Pour the polyoxometalate compound into the reactor, add distilled water with a mass ratio of 1:10 times, heat to 60°C, and stir to dissolve. A precipitant solid was added thereto, and the reaction solution was aged for 2 hours to precipitate a solid, which was filtered and washed with distilled water for 3 times until the pH value of the eluate reached 8. Precipitate in a mug furnace and sinter at 300°C for 6 hours to obtain a solid catalyst of polyoxometalate compound. Its yield was 84%.

Embodiment 3

[0077] Weigh the polyoxometalate compound H with a molar ratio of 1:2.5 4 [SiW 12 o 40 ]·23H 2 O and precipitant NH 4 Cl. Pour the polyoxometalate compound into the reactor, add distilled water with a mass ratio of 1:8 times, heat to 55°C, and stir to dissolve. A precipitant solid was added thereto, and the reaction solution was aged for 6 hours to precipitate a solid, which was filtered and washed with distilled water for 3 times until the pH value of the eluate reached 7. Precipitate in a mug furnace and sinter at 150°C for 4 hours to obtain a solid catalyst of polyoxometalate compound. Its yield was 84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com