Side pumping method of optical-fiber laser

A fiber laser, side-pumped technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as poor repeatability and mechanical instability, and achieve the effect of avoiding thermal melting and non-linear effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

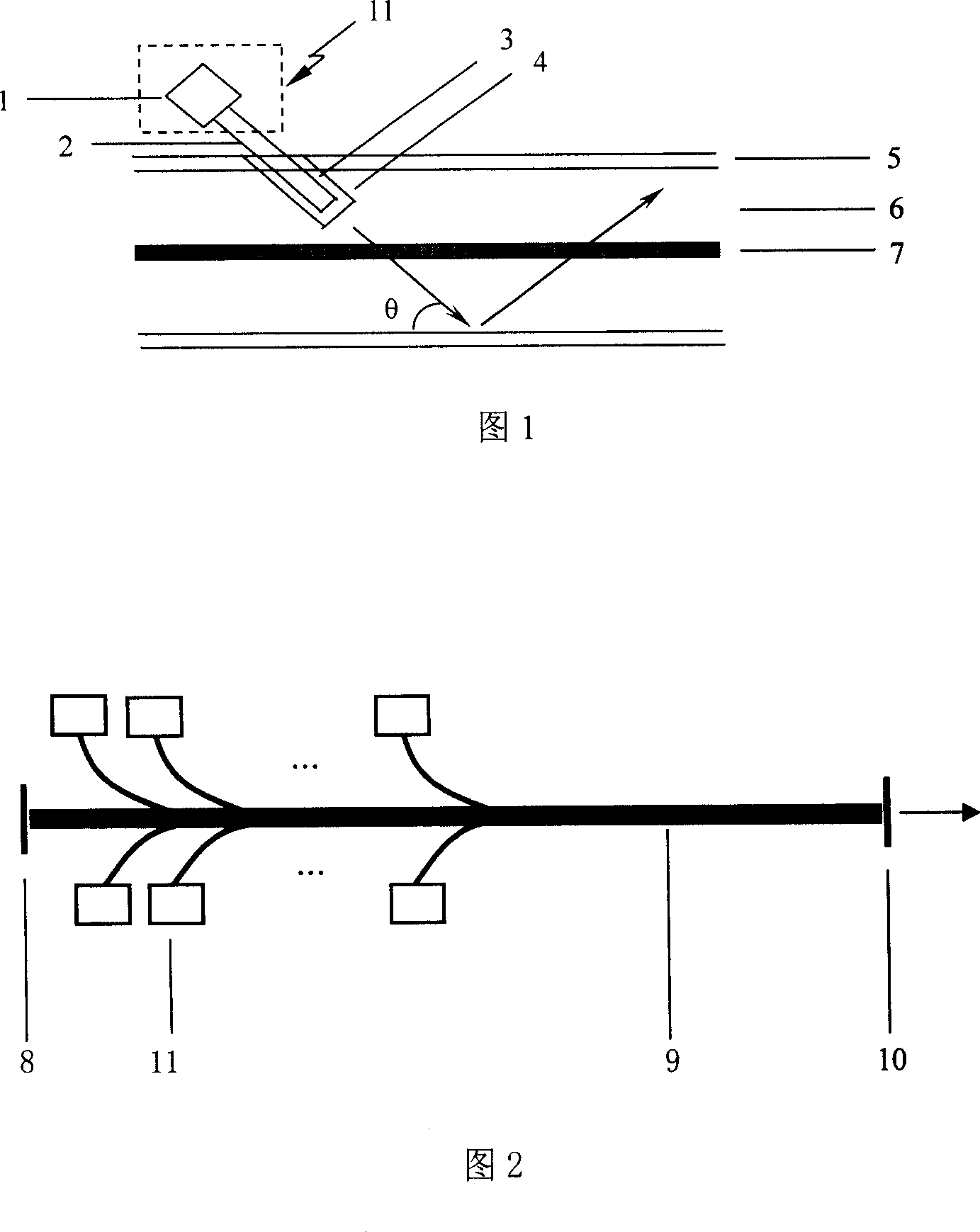

[0030] Fig. 1 is a schematic diagram of the side pumping structure of the present invention. The parameters of the double-clad optical fiber 9 in this embodiment are: core layer diameter: 20 ± 2 μm; inner cladding diameter: 400 ± 15 μm; outer cladding diameter: 550 ± 20 μm ; Core N.A.1 (numerical aperture): 0.06±0.01; Inner cladding N.A.2 (numerical aperture): 0.46±0.01.

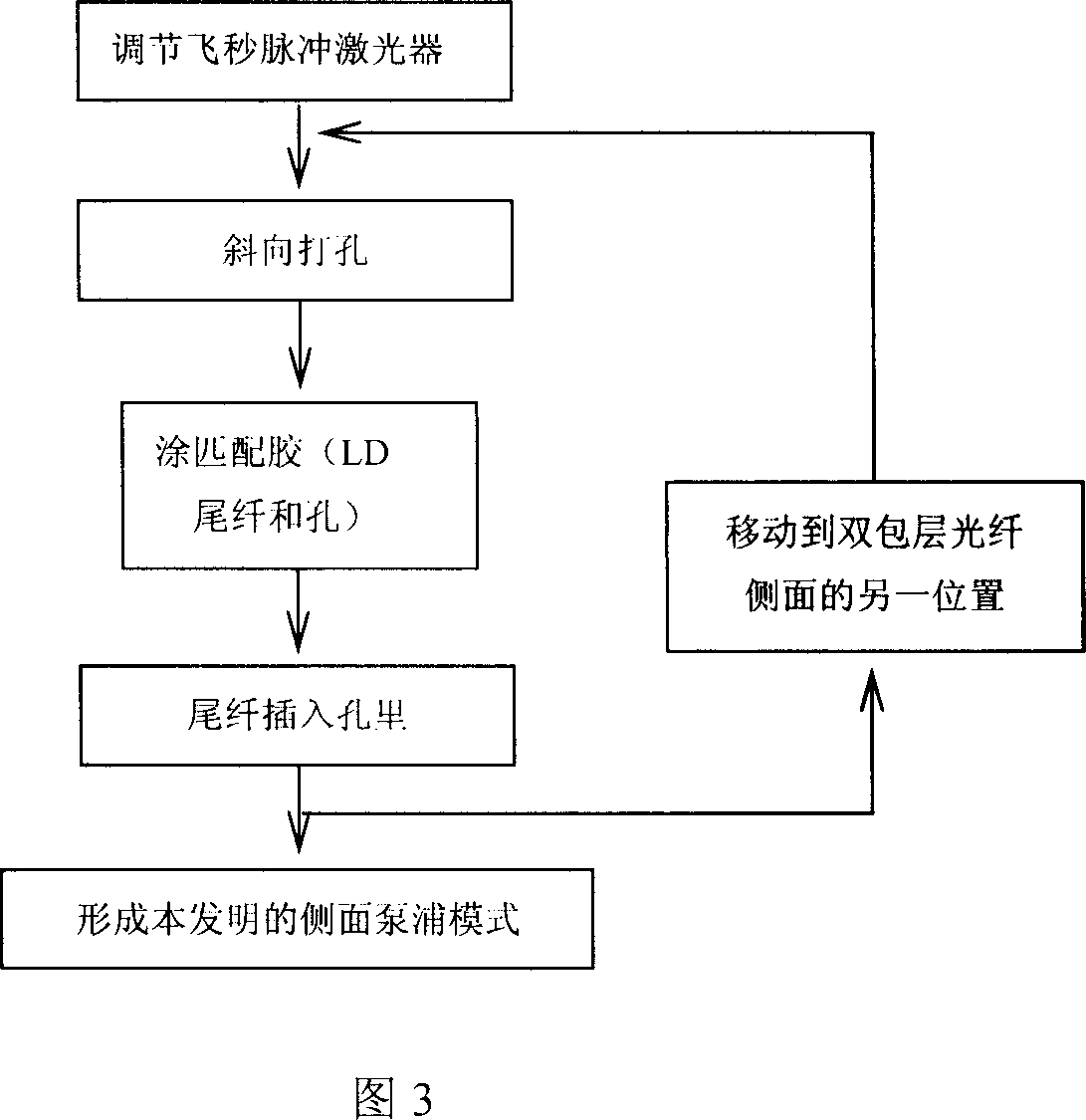

[0031] The side pumping method of the fiber laser of the present embodiment comprises the following steps:

[0032] a) Use a femtosecond pulse laser to drill holes on the side of the double-clad fiber. The femtosecond pulse laser has a wavelength of 800±2nm, a pulse width of 120fs, a pulse frequency of 0.1-1kHz, a peak power of 1000kW, and a spot diameter of The diameter of the light spot is adjustable between 100 μm and 5 mm, and the angle θ between the drilled hole 4 and the double-clad optical fiber is 5 to 30°. The hole 4 passes through the outer cladding 5 of the double-clad fiber and enters the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com