Fluid purifying medium and its production

A fluid purification and medium technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of secondary pollution, manufacturing difficulties, and secondary pollution of purified water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024]In the specific preparation process, the KDF particles, immobilized substance and additives are first mixed thoroughly. The ideal mixing procedure is to mix the immobilized substance and stabilizer first, then add KDF particles and continue mixing. After mixing, the surface of KDF should be evenly covered on immobilized particles. The mixture is then filled into molds at a packing density of 0.5 to 5.0 grams per cubic centimeter, preferably 1.2 to 1.8 grams per cubic centimeter. The filled mold is heated to the melting, sintering or solidification temperature of the fixation. The way to raise the temperature is to raise the temperature gradually. First, raise the temperature to 5 to 10 degrees lower than the melting point, maintain it for 0.25 to 24 hours, and the best choice is 15 to 30 minutes, and then raise the temperature to the melting point, or 0.1 to 0.1 degrees higher than the melting point. 100°C, and keep at this temperature for 0.25 to 48 hours, the best cho...

example 1

[0035] Example 1: Preparation of immobilized KDF cylinder

[0036] KDF filter material, particle diameter 100 mesh (0.14 mm), 240 grams.

[0037] Immobilized product, polyvinylidene fluoride powder, particle diameter 35 microns, 45 grams, melting point 170°C.

[0038] Stabilizer, water, 28 g.

[0039] After the polyvinylidene fluoride powder and water are fully mixed, add KDF particles and continue to mix the surface of KDF to evenly cover the immobilized particles; fill the mixture into a mold with a filling density of 1.78 grams per cubic centimeter; heat the filled mold to 165 ℃, keep warm for 1 hour, then raise the temperature to 171°C, keep warm for 0.5 hour; apply a pressure of 0.1MP to the mold during the heating and heat preservation process; quench and demould after the heat preservation time is over. After thorough cooling, a cylindrical immobilized KDF with an outer diameter of 5 cm, an inner diameter of 2.8 cm, a wall thickness of 1.1 cm and a length of 11 cm was...

example 2

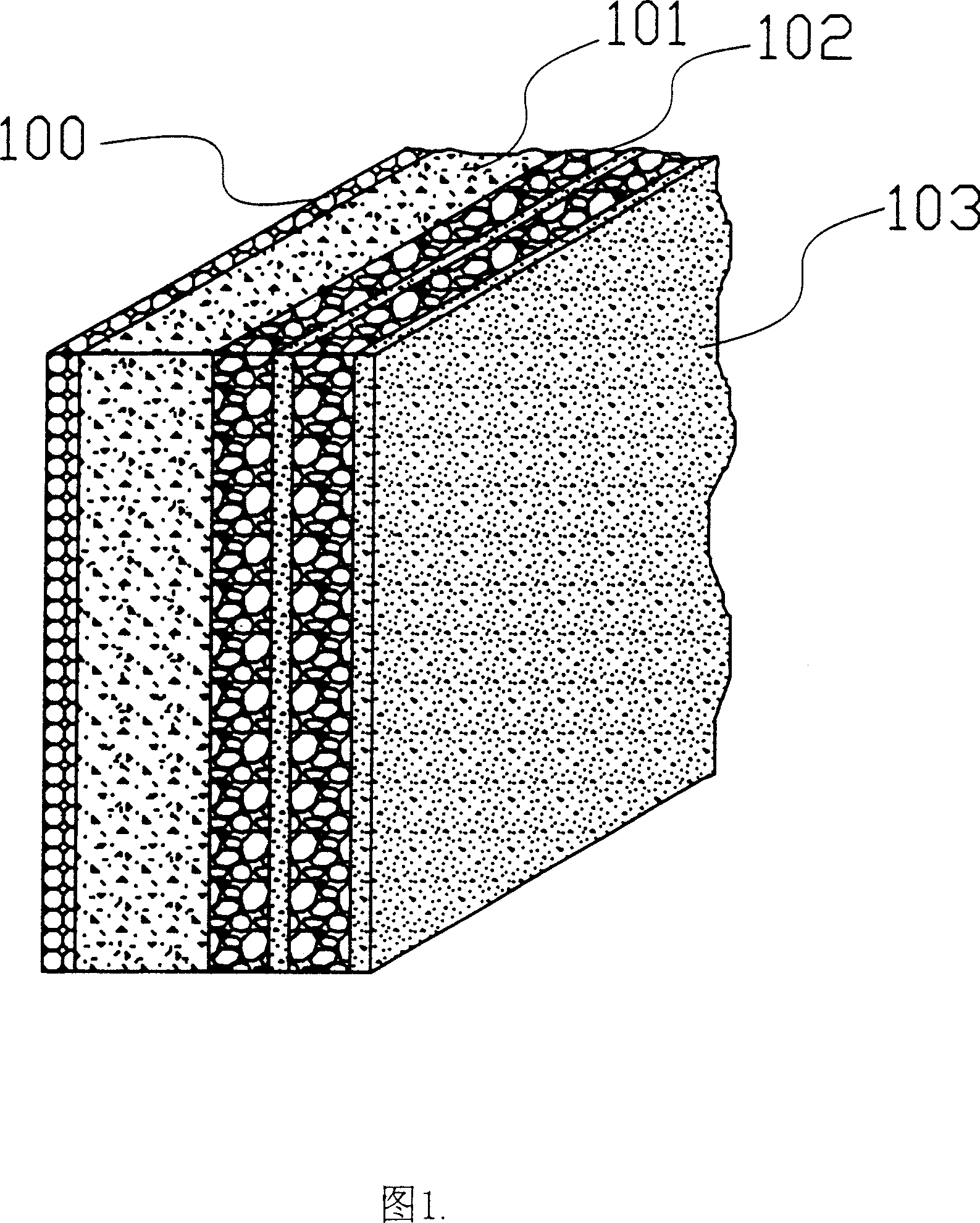

[0040] Example 2: Preparation of an integrated multifunctional purification medium

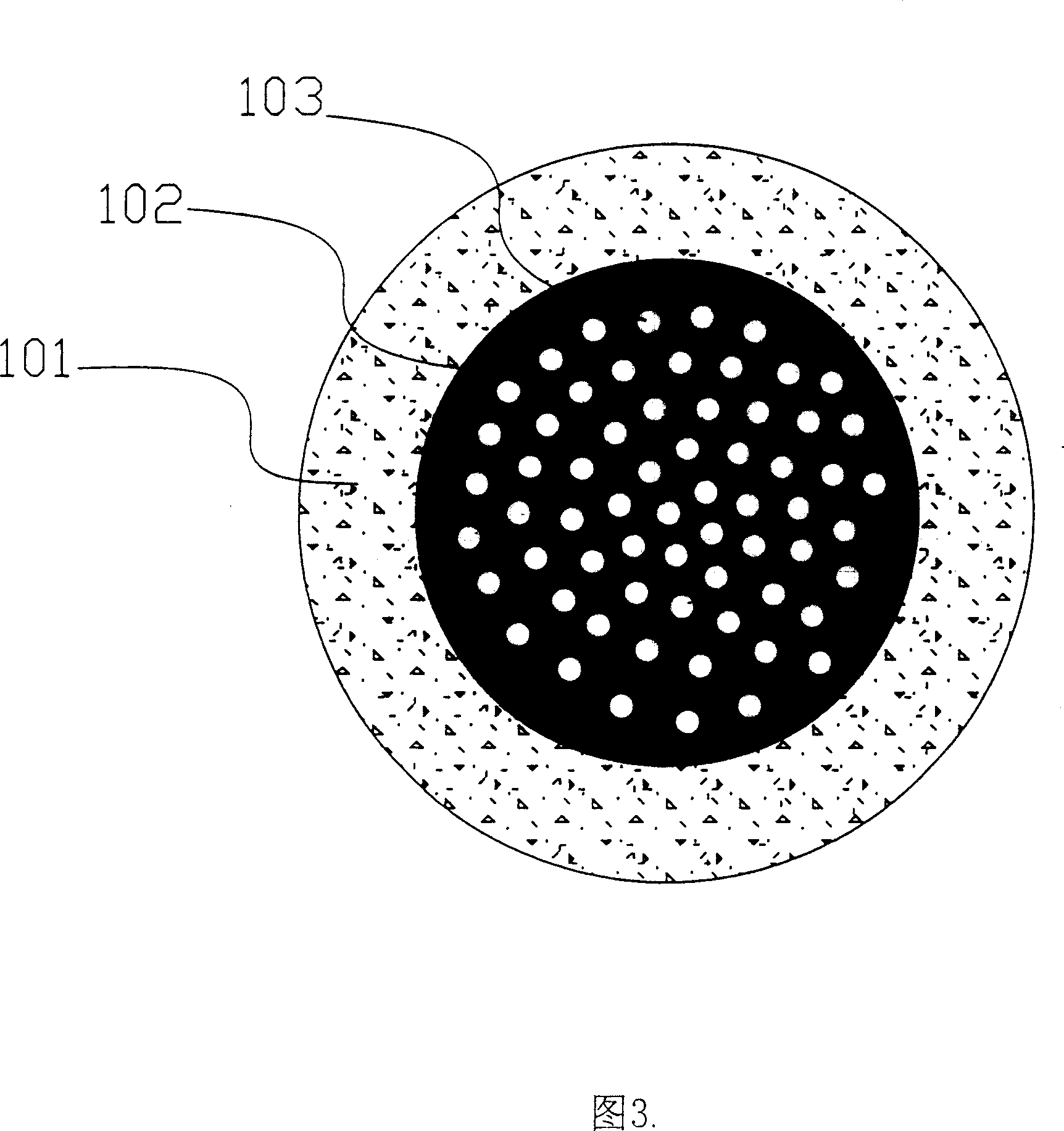

[0041] The cylindrical non-woven pre-filter material has a wall thickness of 0.3 mm, an inner diameter of 50 mm, a height of 100 mm, and a nominal pore size of 35 microns.

[0042] Immobilized KDF, KDF particle diameter 0.07 to 0.17 millimeters, after immobilization, produce inner diameter 30 millimeters, outer diameter 50 millimeters, the garden cylinder of height 100 millimeters. The cylinder has a porosity of 30% by volume and a nominal pore size of 25 microns.

[0043] Activated carbon fiber felt, 4 mm thick, 100 mm wide, 240 mm long, 150 g / m 2 , the pore diameter is 20 Ȧ.

[0044] Positively charged membrane, 0.3 mm thick, 100 mm wide, 260 mm long, nominal pore size 8 microns.

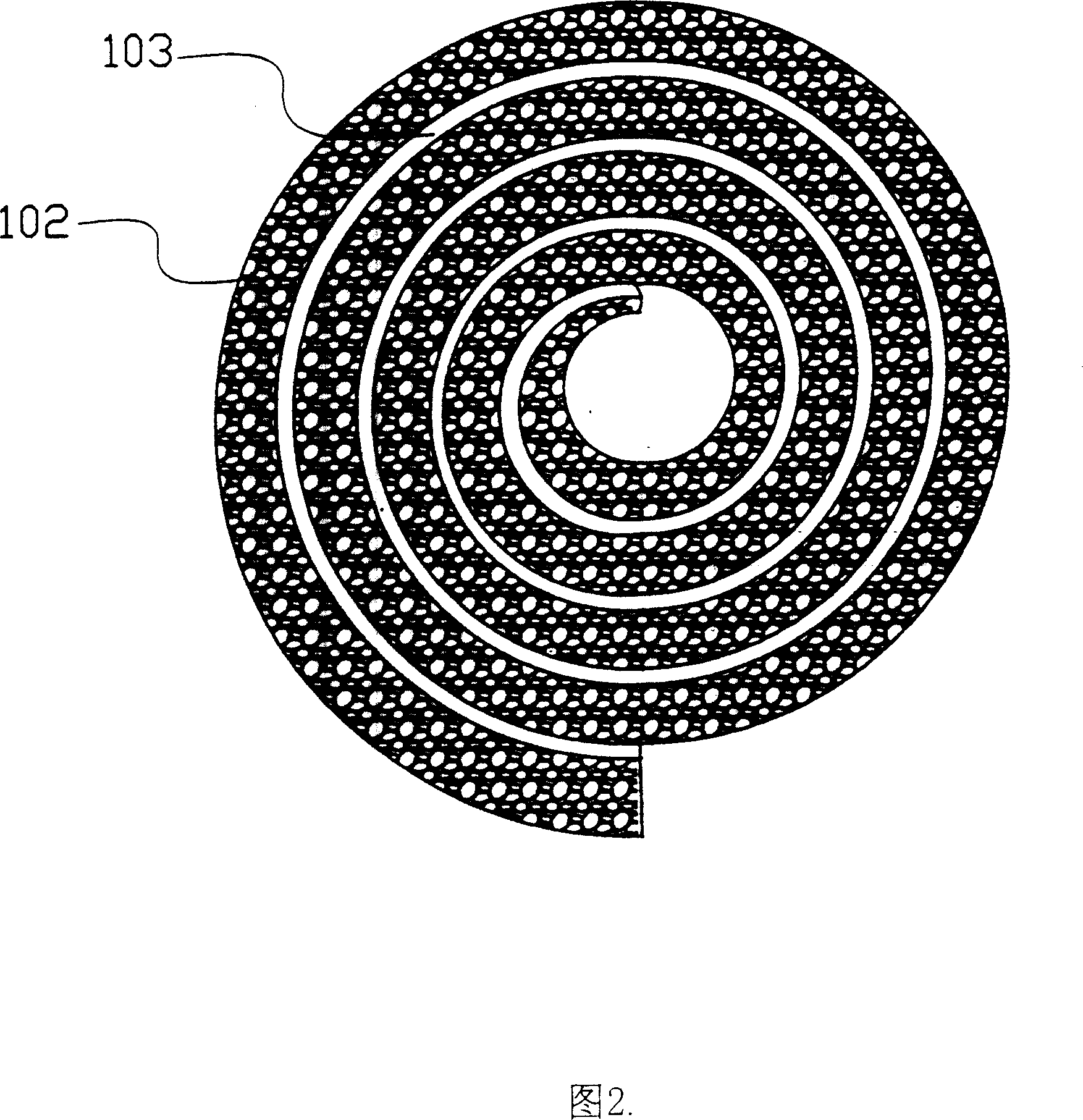

[0045] The activated carbon fiber felt and the positively charged membrane are superimposed and rolled into a spiral structure, and the activated carbon fiber felt is located outside the positively charged memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com