Device structure and its production for single-modulus quantum cascade laser

A technology of quantum cascade and manufacturing method, which is applied to laser components, optical waveguide semiconductor structure, laser, etc., can solve the problems of complex manufacturing process, achieve the effect of simple device process and avoid complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

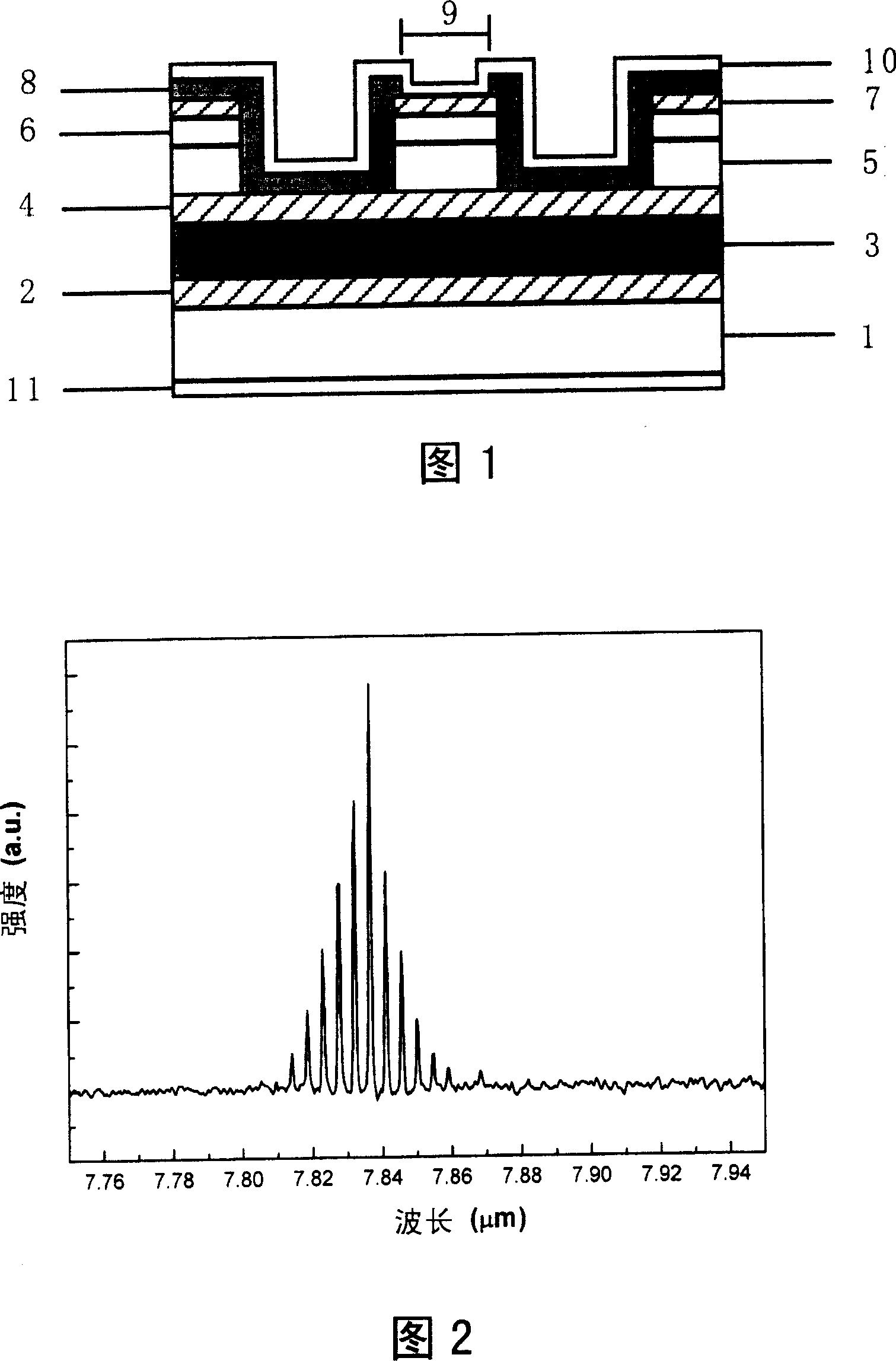

[0063] Please refer to Fig. 1 again, the present invention relates to a kind of device structure of single-mode quantum cascade laser, comprising:

[0064] n-type indium phosphide substrate 1 as the lower cladding layer;

[0065] n-type InGaAs lower waveguide layer 2, the lower waveguide layer 2 is fabricated on the n-type substrate 1, and is used to increase the refractive index of the waveguide core layer and enhance light confinement;

[0066] 35 cycles of alternating InGaAs / InAlAs active layer 3, the active layer 3 is fabricated on the lower waveguide layer 2 as a light-emitting area;

[0067] n-type InGaAs upper waveguide layer 4, the upper waveguide layer 4 is fabricated on the active layer 3, and is used to increase the refractive index of the waveguide core layer and enhance light confinement;

[0068] n-type indium aluminum arsenic upper cladding layer 5, the upper cladding layer 5 is fabricated on the upper waveguide layer 4;

[0069] n-type InGaAs highly doped con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com