Calcium alginate gel bead with shell of porous calcium carbonate microsphere and its preparing method

A technology of calcium carbonate microspheres and calcium alginate, which is applied in the directions of non-active ingredients, such as medical preparations, pharmaceutical formulations, inorganic non-active ingredients, etc., can solve the problems of affecting the use effect, easy to break, and low surface strength of gel beads. , to achieve the effect of good adsorption performance of active substances and improvement of surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

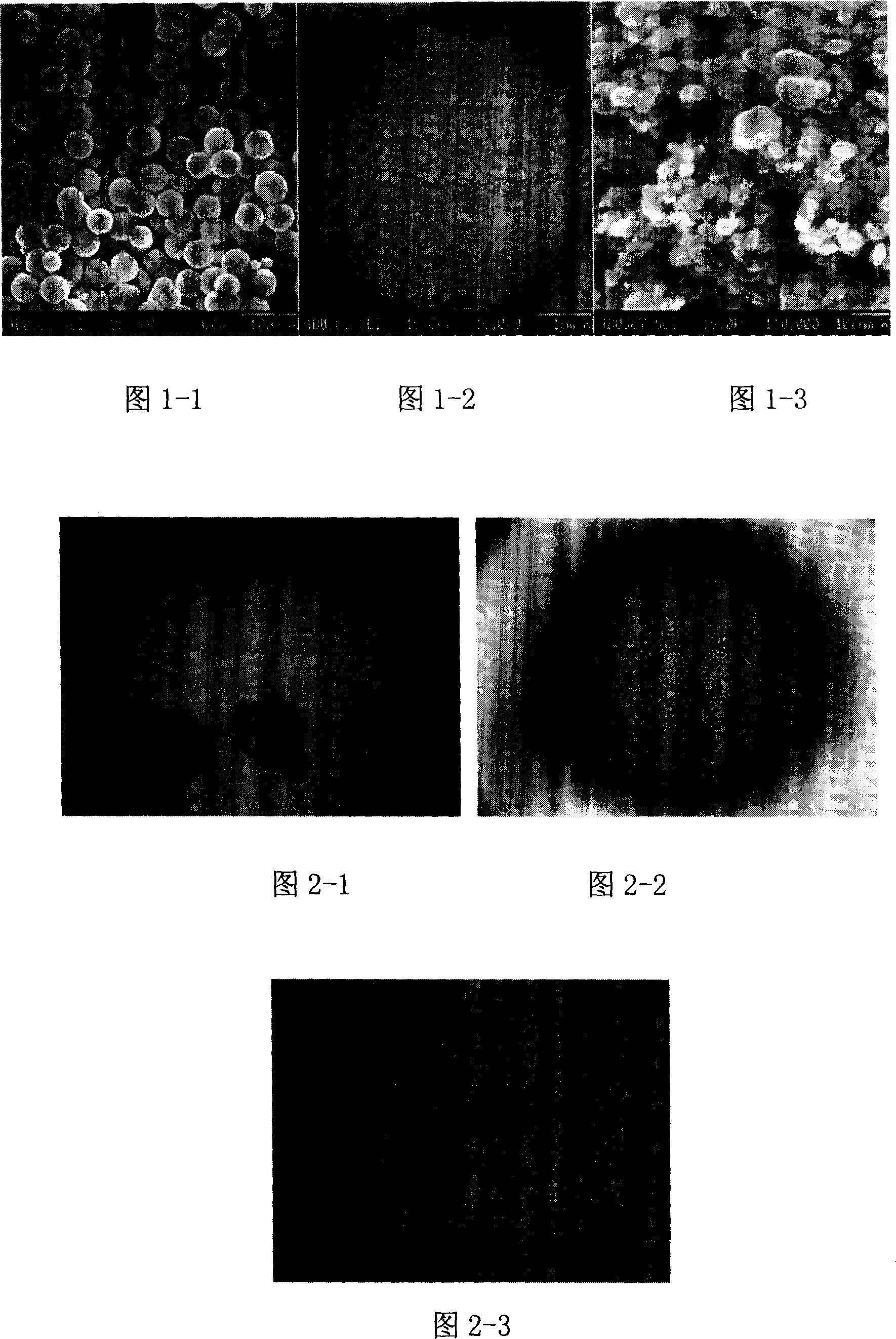

[0028] The porous calcium carbonate microspheres (see Fig. 1) of 40g 5 μm are uniformly dispersed in the sunflower oil of 4L, then 1L 1% sodium alginate aqueous solution is added dropwise in the mixed solution of porous calcium carbonate microspheres and sunflower oil, at 150rpm Stir for 10 min at a rotating speed of 10 min to form an emulsion. Add 100mL 200g / L gluconolactone aqueous solution dropwise to the emulsion, and continue to stir for 10 minutes. The prepared calcium alginate gel beads have a layer of porous calcium carbonate microspheres on the surface (see Figure 2), with regular appearance and high degree of sphericity. The particle size is between 100 μm and 1000 μm.

Embodiment 2

[0030] Evenly disperse 30g of 5 μm porous calcium carbonate microspheres in 4L of sunflower oil, then add 1L of 1% sodium alginate aqueous solution dropwise to the mixed solution of porous calcium carbonate microspheres and liquid paraffin, and stir at 150rpm for 10min. An emulsion is formed. Add 100mL 200g / L gluconolactone aqueous solution dropwise to the emulsion, and continue to stir for 10 minutes. The prepared calcium alginate gel beads have a layer of porous calcium carbonate microspheres on the surface. 1000μm.

Embodiment 3

[0032] Evenly disperse 50g of 1 μm porous calcium carbonate microspheres in 4L of sunflower oil, then add 1L of 1% sodium alginate aqueous solution dropwise to the mixture of porous calcium carbonate microspheres and decane, and stir at 150rpm for 10min. An emulsion is formed. Add 100mL 200g / L gluconolactone aqueous solution dropwise to the emulsion, and continue to stir for 10 minutes. The prepared calcium alginate gel beads have a layer of porous calcium carbonate microspheres on the surface. 1000μm.

[0033] In the foregoing examples, the coverage of the porous calcium carbonate microspheres on the surface shell of the prepared calcium alginate gel beads is regulated by the weight ratio of the porous calcium carbonate microspheres to the sodium alginate aqueous solution. Gel beads with different surface strengths and penetration rates need to be prepared.

[0034] As can be seen from the above, the present invention can improve the surface strength of the gel beads and im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com