Process and apparatus for separating mixed solution of liquid petrolatum and xylene

A technology of mixed solution and separation method, which is applied in the direction of distillation purification/separation, petroleum industry, recovery/refining of mineral wax, etc. It can solve the problems of increased production cost, waste of raw materials, inconvenient recovery, etc., and achieves a high degree of automation and reduced The effect of production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

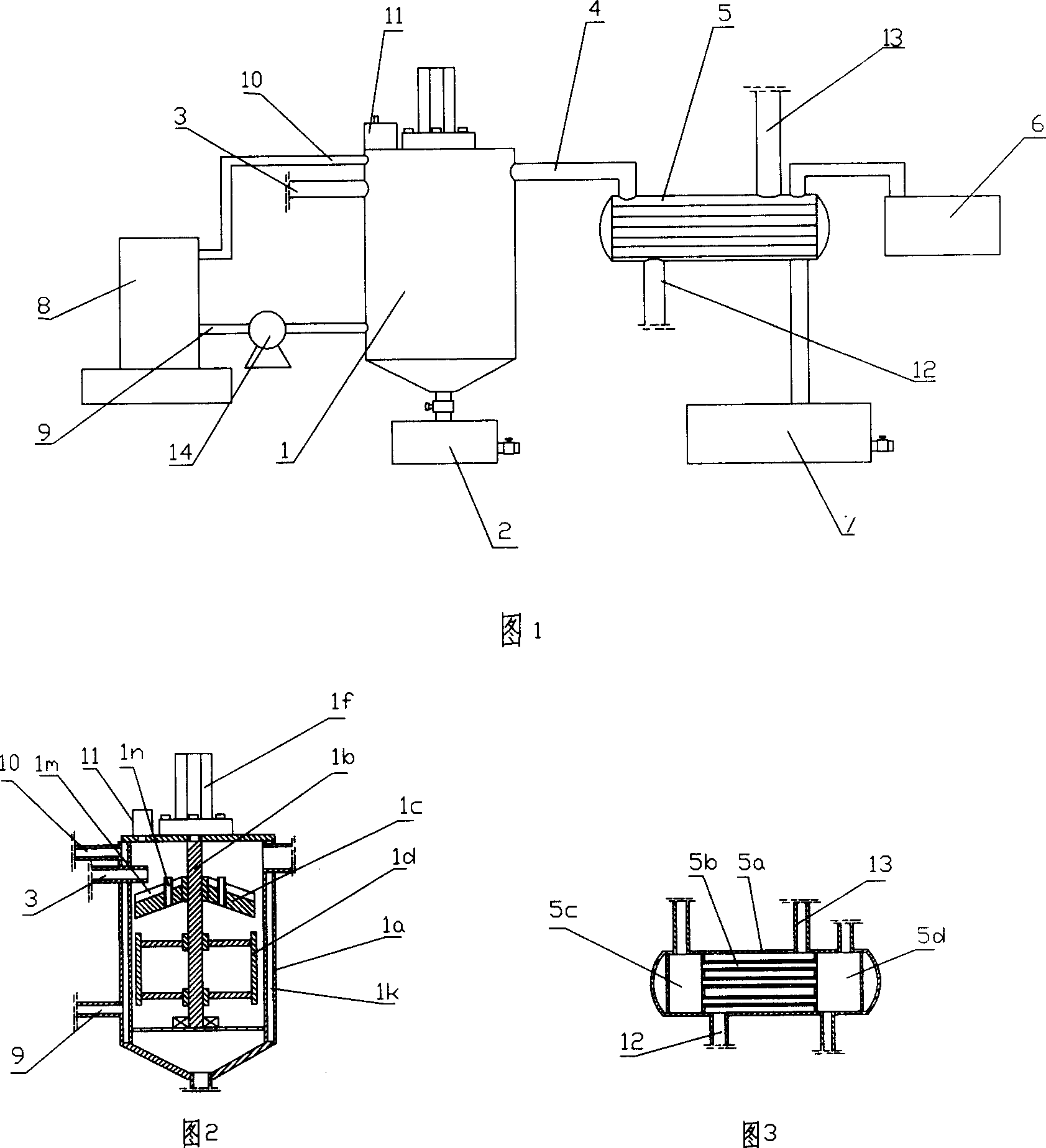

[0013] It is used in Shandong Aidi Polymer Material Co., Ltd. After the special equipment is connected to the extraction process in the ultra-high molecular weight polyethylene fiber production process, a white mineral oil and xylene mixed solution outflow pipe is installed on the extraction box. This outflow pipe Connect with the white mineral oil and xylene mixed solution input pipe 3 on the thin film evaporator 1, adjust the temperature controller so that the temperature in the cavity of the thin film evaporator 1 is higher than the boiling point of xylene, and the xylene in the thin film evaporator 1 is vaporized , separated from the white mineral oil, the separated white mineral oil flows downward into the white mineral oil recovery tank 2, and then the recovered white mineral oil is sent into the dissolution tank, the air pump 6 is turned on, and vaporized under the action of the negative pressure chamber 5d The xylene in the condenser 5 flows into the condenser 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com