Preparing and assembling process of inert cermet anode for aluminium electrolysis

A cermet, inert anode technology, applied in the field of anodes used in the production of molten salt electrolysis, can solve the problems that the current intensity is difficult to meet the requirements, and the anode material is difficult to enlarge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

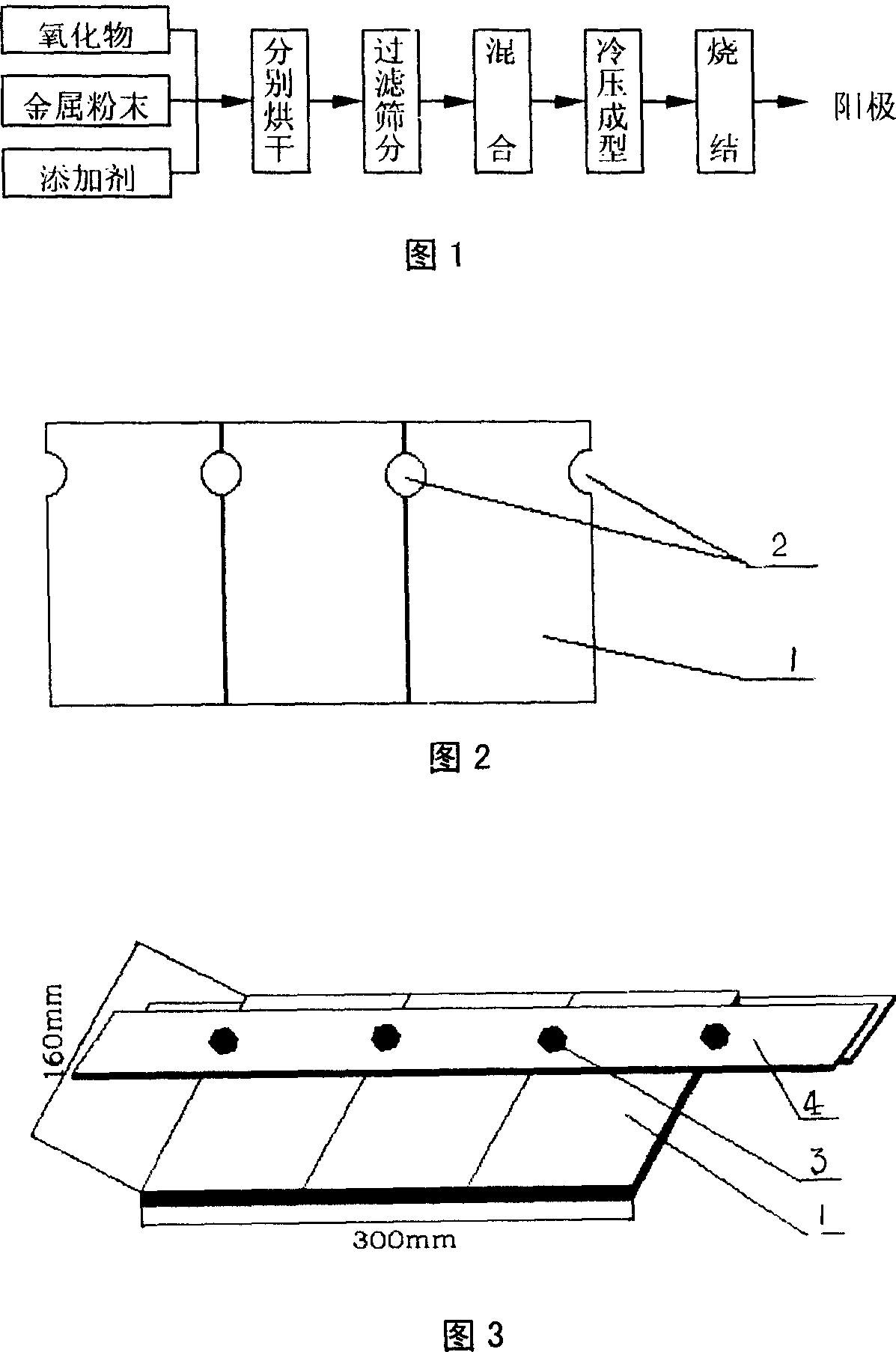

[0026] Example Take Fe 2 o 3 , NiO and metal Cu and liquid paraffin are dried with hot air according to conventional methods respectively, and pass through a 60-mesh sieve, according to liquid paraffin / (NiO+Fe 2 o 3 +Cu)=7% mixed evenly, in which NiO, Fe 2 o 3 , The mass ratio of Cu is NiO 52%, Fe 2 o 3 31%, Cu 17%; use 1MPa / cm of the obtained mixture under a 250t press 2 Pressure cold pressing to prepare cermet inert anode compacts; heat the compacts to 1250°C at normal pressure in a silicon carbide rod furnace according to the predetermined sintering system and keep them warm for 5 hours to sinter the anode compact materials and cool them to room temperature to obtain metal Ceramic inert anode product, its size is 160mm×100mm, conductivity is 72Ω -1 cm -1 , the apparent density is 5.3g / cm 3 .

[0027] Use a grinding wheel to grind and polish the surface of the cermet inert anode plate 1, and dig semicircular grooves 2 on both sides above it as shown in Figure 2. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com