Brake shoe for hump decelerator and manufacturing method thereof

A manufacturing method and technology of a reducer, applied in chemical instruments and methods, other chemical processes, friction linings, etc., can solve problems such as poor heat resistance, polluted operating environment, loud noise, etc., to improve production safety and improve operation. environment, the effect of improving marshalling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

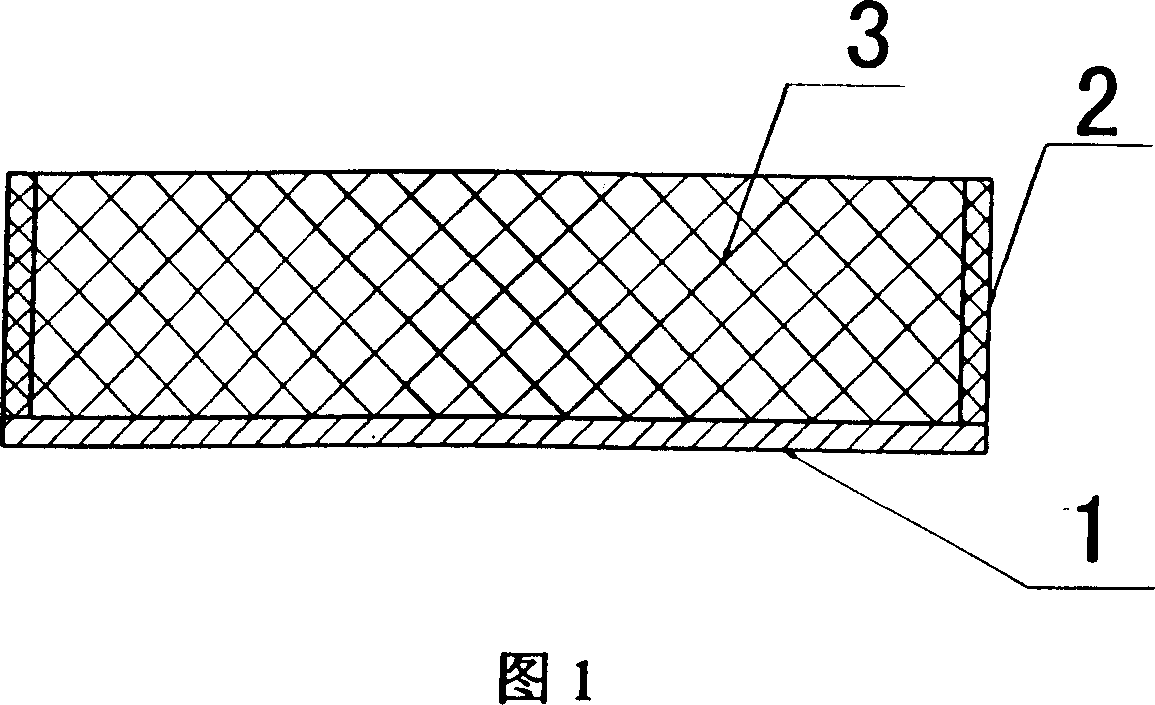

Image

Examples

Embodiment 1

[0038] Brake shoe body:

[0039] Component Weight percent

[0040] Aramid fiber (Kevlar Pulp979) 2

[0041] carbon fiber 5

[0042] A6 resin 20

[0043] Corundum 5

[0044] Clay 20

[0045] Feldspar 18

[0046] Barite 25

[0047] graphite 5

[0048] Put the raw materials into the rake type mixer in proportion, stir for 5 minutes, and set aside.

[0049] The adhesive silk cloth (thickness 0.5 ~ 3mm, door width 1000mm) is impregnated with A6 resin, the gluing rate is 20% by weight, cut into corresponding size, and pasted on the inner wall of the mold and / or the upper mold. The total thickness of one side is 3-5mm.

[0050] Pour the pressed plastic of the brake shoe body into the mold, control the mold temperature to 170-190°C, the pressure to 15MPa, and the time to 5min.

[0051] The properties of the made material are as follows:

[0052] temperature(℃)

100

...

Embodiment 2

[0059] Brake shoe body:

[0060] Component Weight percent

[0061] Kevlar Pulp979 1

[0062] steel fiber 25

[0063] A6 resin 25

[0064] corundum 4

[0065] Clay 10

[0066] Feldspar 15

[0067] Barite 15

[0068] graphite 5

[0069] Put the raw materials into the plow rake mixer in proportion, stir for 5 minutes, and set aside.

[0070] The continuous long fiber adopts 1.5mm glass fiber cloth.

[0071] The bottom reinforcement material is made of iron plate with a thickness of 4mm, the surface is galvanized, and treated with an adhesive, so that it can be well bonded to the brake shoe body material.

[0072] Manufacturing method is the same as embodiment 1.

[0073] The properties of the prepared material are as follows:

[0074] temperature(℃)

100

150

200

250

300

0.50

0.52

0.53

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com