Reinforced fiber board with medium-density

A fiberboard, medium-density technology, used in household components, flat products, household appliances, etc., can solve the problems of brittleness of wear-resistant paper or decorative paper, reduced production efficiency, decreased mechanical properties, etc., to reduce raw material costs and save wood. , the effect of alleviating the tight supply of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

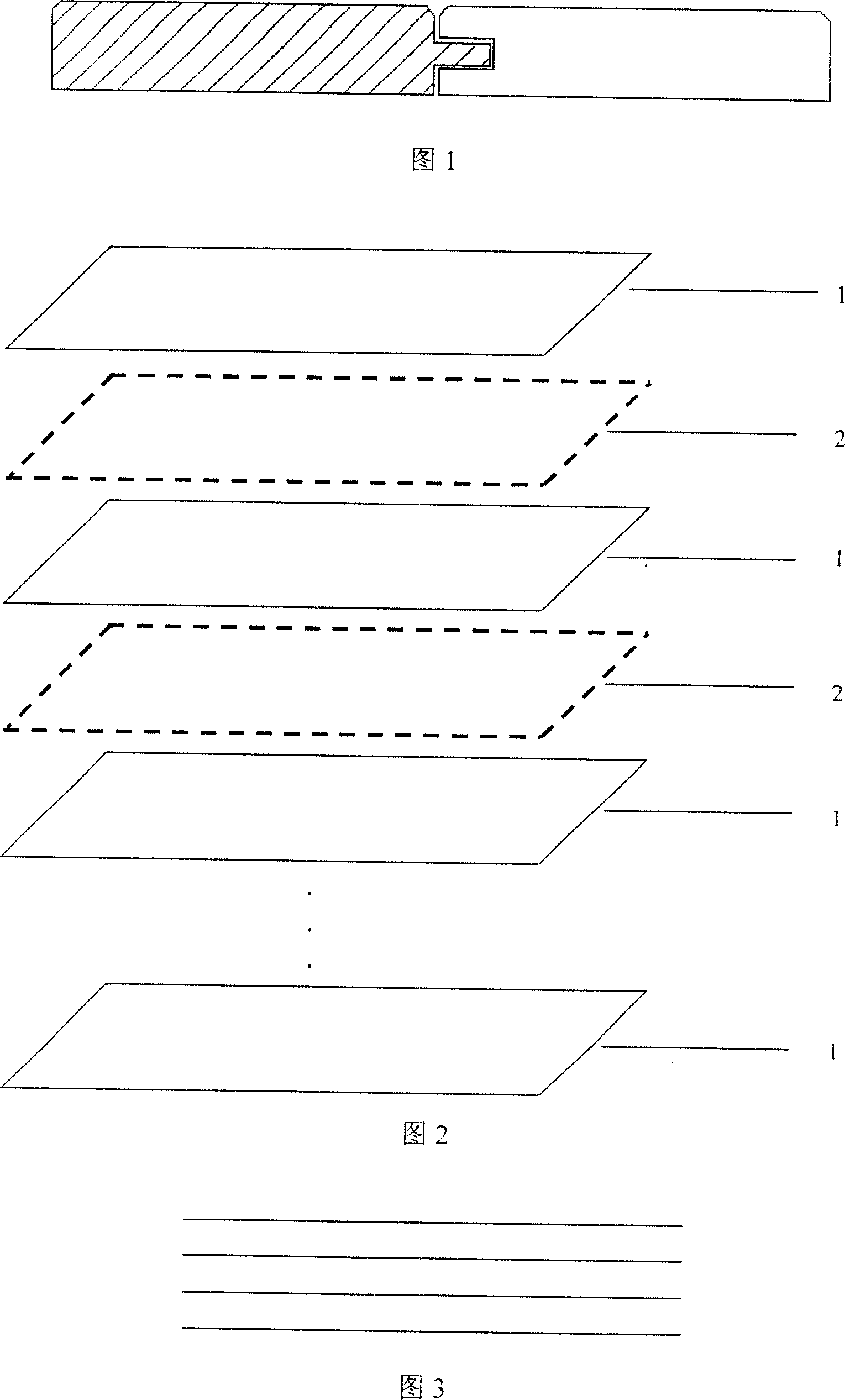

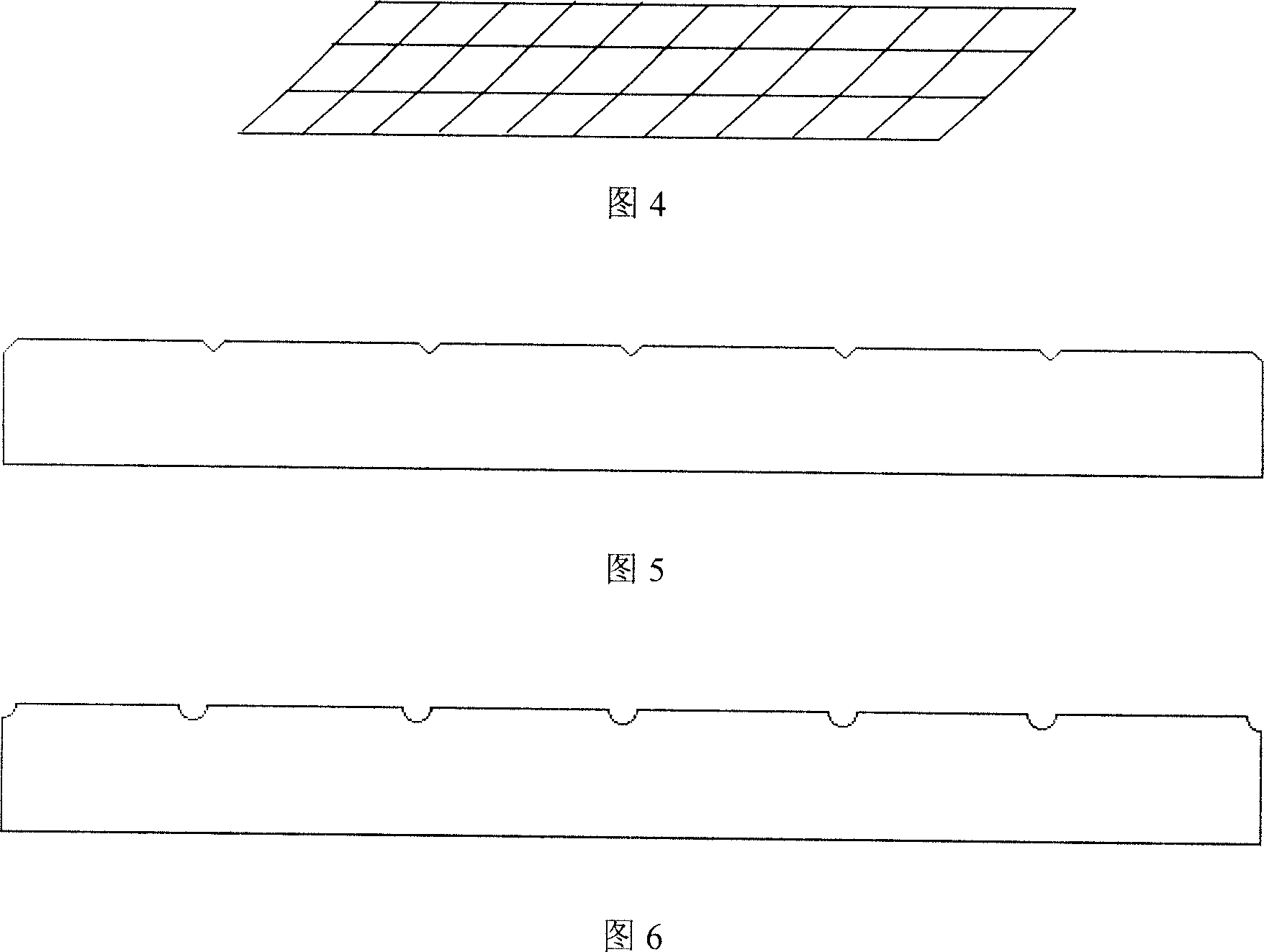

Embodiment 1

[0030] 21.5 parts by weight of the bamboo fiber spraying of 100 parts by weight of the drying process are made of 5 parts by weight of anti-mold agent, 1.5 parts by weight of curing agent, 3 parts by weight of paraffin emulsion waterproofing agent and 12 parts by weight of urea-formaldehyde glue; Moso bamboo is cut into bamboo wires with a diameter of 0.6mm±0.20 and then woven into a net shape. When paving and forming, the bamboo wire mesh is placed in the bamboo fiber, pre-pressed, and the steel formwork with V-shaped ribs on the upper formwork is used for heating. The thickness is controlled to be about 8mm±0.20, the hot-pressing temperature is 160-165°C, and the hot-pressing cycle is 270s; after curing and sanding, the finished reinforced medium density fiberboard is obtained.

Embodiment 2

[0032] Spray 21.5 parts by weight of 5 parts by weight of antifungal agent, 1.5 parts by weight of curing agent, 3 parts by weight of paraffin wax emulsion waterproofing agent and 12 parts by weight of urea-formaldehyde glue to the dried straw fiber of 100 parts by weight. , pre-press after paving and molding, cut the moso bamboo into bamboo wires with a diameter of 0.6mm±0.20 and then weave them into a net shape, place the bamboo wire mesh on the upper and lower surfaces of the green body, and use a steel formwork with V-shaped convex ribs on the upper formwork Carry out hot pressing, control the thickness of about 8mm±0.20, hot pressing temperature 160-165 ℃, hot pressing cycle 270s; after curing and sanding, the finished reinforced medium density fiberboard is obtained.

Embodiment 3

[0034] 21.5 parts by weight of 5 parts by weight of antifungal agent, 1.5 parts by weight of curing agent, 3 parts by weight of paraffin wax emulsion waterproofing agent are sprayed on the mixed fiber made up of 70 parts by weight of straw fiber and 30 parts by weight of bamboo fiber after drying. and 12 parts by weight of urea-formaldehyde glue, pre-press after paving and forming, cut the moso bamboo into bamboo wires with a diameter of 0.6mm ± 0.20 and weave them into a mesh, and place the bamboo mesh on the upper and lower surfaces of the green body , using the steel formwork with V-shaped convex ribs on the upper formwork for hot pressing, the thickness is controlled to be about 8mm±0.20, the hot pressing temperature is 160-165°C, and the hot pressing cycle is 270s; after curing and sanding, the finished product is reinforced with medium density fiberboard.

[0035] Spray 1.5 parts by weight of curing agent and 12 parts by weight of urea-formaldehyde glue on 100 parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com