Method for separating and extracting acetic acid and propanoic acid from waste acetic acid produced from methanol low pressure carbonyl method

A technology of low-pressure carbonyl method and waste acetic acid, which is applied in the separation/purification of carboxylic acid compounds, the preparation of carboxylic acid by carbon monoxide reaction, organic chemistry, etc., which can solve the problems of resource waste and increase product cost, and achieve low cost and reduce resource waste And environmental pollution, the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

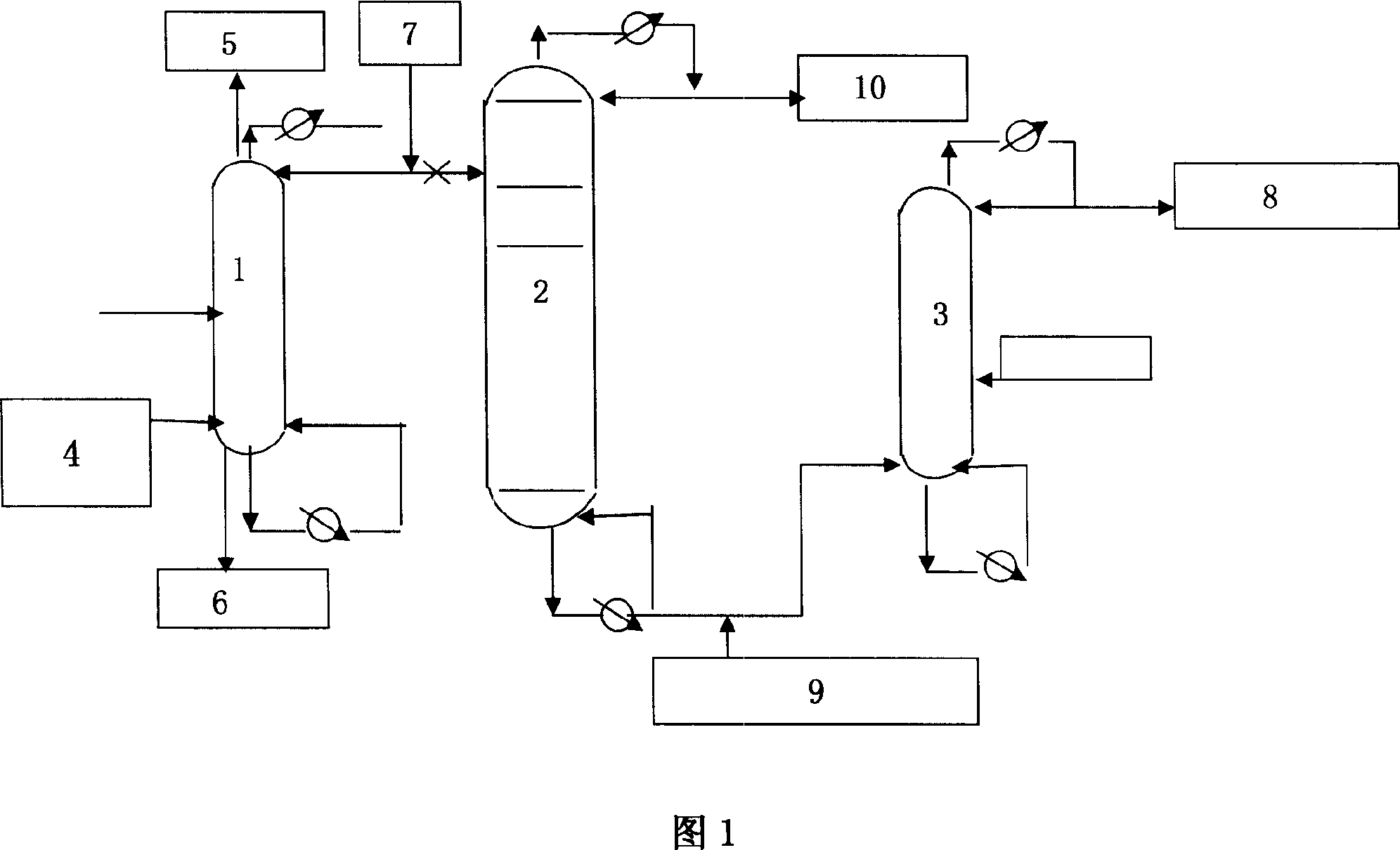

Method used

Image

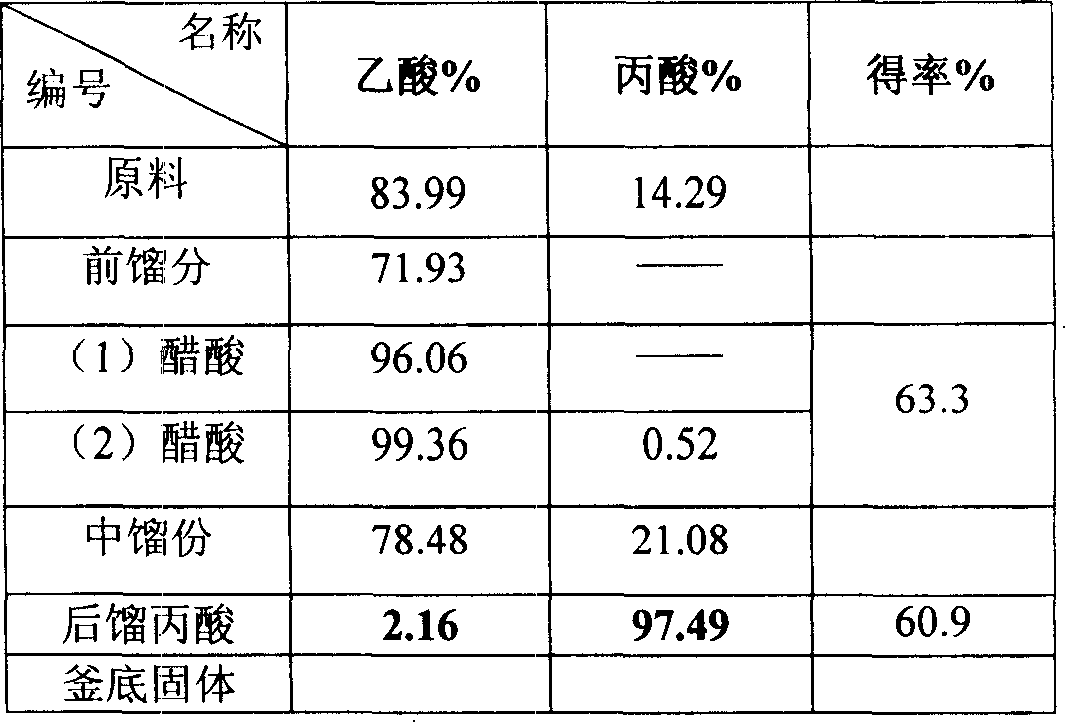

Examples

Embodiment 2

[0035] Tower 1: The vacuum insulation rectification column is used in the laboratory, the height of the vacuum section is 750mm, the tower diameter is 20mm, and 316L stainless steel 2×2mmθ mesh ring packing is installed inside. The conversion index of packing and tray = 22 trays / m, so 22mm Equivalent to 5 trays. The feed is fed at the bottom of the tank, the heat of the system is controlled by a pressure regulator in the tank, and the reflux ratio is controlled by a fractionating head at the top of the tower. The waste acetic acid 4 discharged from the production process of the acetic acid plant is subjected to intermittent rectification in column 1, with a reflux ratio of 8:1, and low-boiling impurities 5 below T≤115°C are removed at the top and high-boiling substances and solids above 150°C are discharged at the bottom Impurity 6, the amount of high and low boiling impurities accounts for about 9% of the total amount of spent acid, (experimental data is provided below), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com