Magnetron sputtering method for preparing HA/YSZ/Ti6Al4V gradient bioactive composite material

A magnetron sputtering and composite material technology, applied in sputtering plating, metal material coating process, ion implantation plating and other directions, can solve the problems of coating peeling, restricting the repair of bone defects, harmful thermal stress of the coating, etc. , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

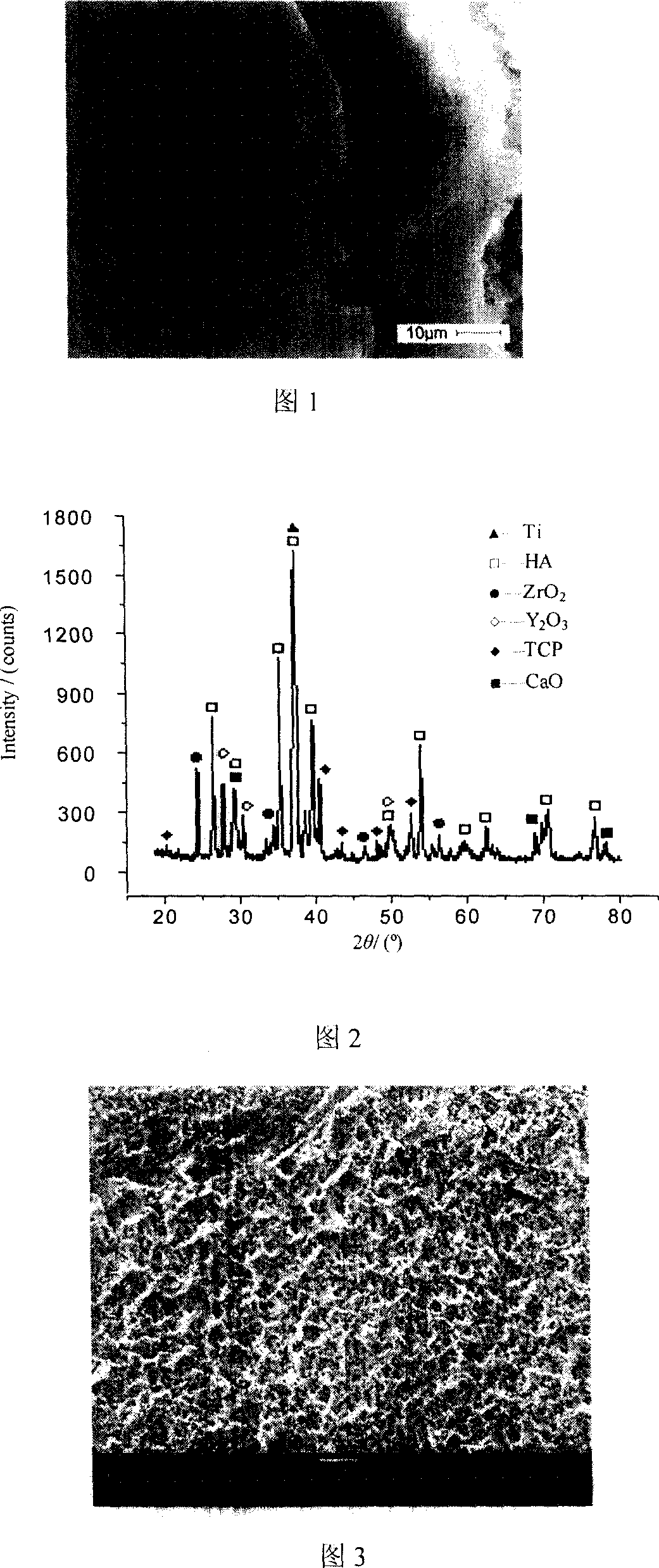

[0021] The magnetron sputtering process is used to prepare an artificial bone implant based on the HA / YSZ gradient biocoating on the Ti6Al4V surface. The present invention will now be further described in conjunction with examples.

[0022] (1) Preparation of magnetron sputtering HA target and HA / YSZ composite target

[0023] The nano-level HA powder was prepared by hydrothermal synthesis method, and 60 g of HA powder was weighed, dried in a blast drying box, and ground and sieved. Use ZRY55 type multifunctional vacuum hot pressing sintering furnace to prepare HA target, hot pressing pressure 5t, hot pressing temperature 1150℃, hot pressing atmosphere N 2 , After maintaining the pressure for 4h, cooling with the furnace to obtain a magnetron sputtering HA target with a specification of 60mm×5mm.

[0024] Add YSZ powder to HA powder to configure HA / YSZ composite powder. The weight of YSZ powder accounts for 20%, 40%, 60%, and 80% of the total weight of the composite powder in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com