Ultraviolet curable organopolysiloxane composition, silicone gel cured product and method for producing same, and pressure sensor

a technology of organopolysiloxane and ultraviolet curable organopolysiloxane, which is applied in the direction of fluid pressure measurement, fluid pressure measurement by electric/magnetic elements, instruments, etc., can solve the problems of difficult to adjust the cured product to the desired hardness or penetration, corroding of the substrate, and requiring enormous energy, time and equipment, etc., to achieve effective curability, easy to adjust, and good surface cure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0064]Examples and Comparative Examples are given below by way of illustration of the invention and not by way of limitation. In Examples, “pbw” is parts by weight, and Me stands for methyl. The viscosity is measured at 25° C. by a rotational viscometer.

Component (A)

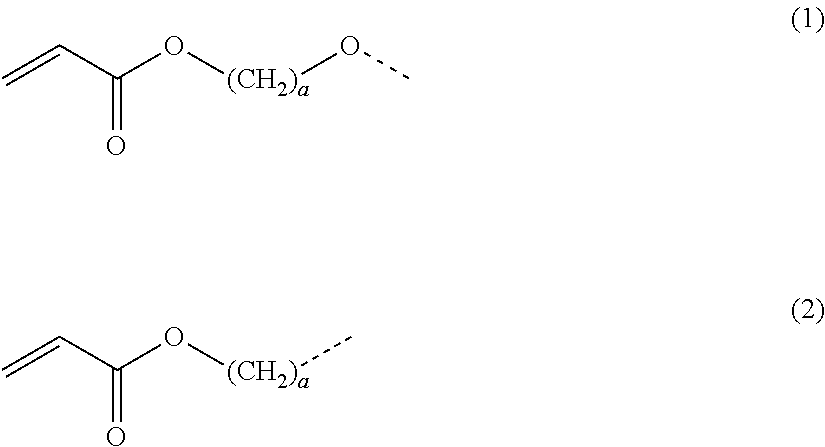

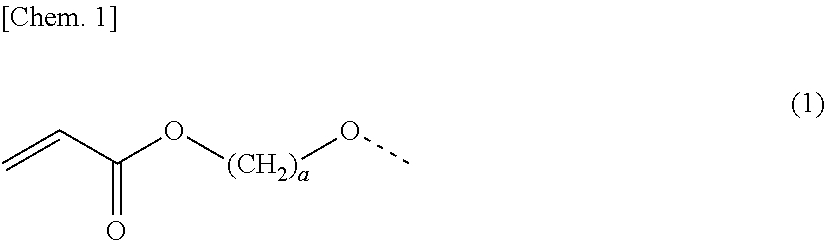

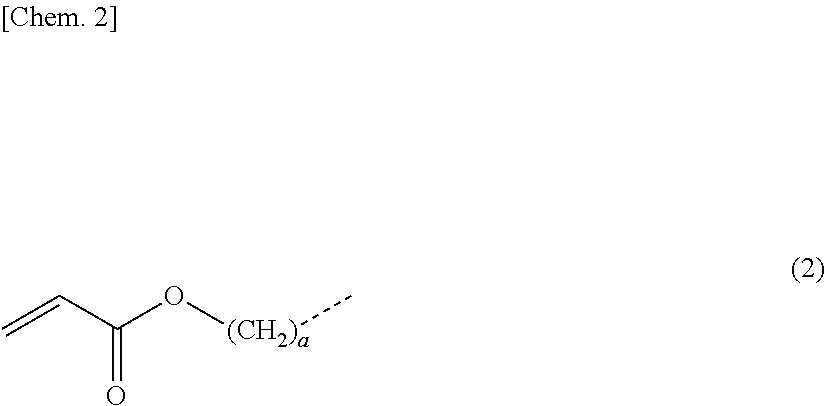

[0065](A-1) linear dimethylpolysiloxane based on a backbone composed of repeating dimethylsiloxane units and containing 4 acryloxyethyloxy groups per molecule (two groups at each of the both ends of the molecular chain), represented by the formula (7), having a viscosity of 6,000 mPa·s

[0066][0067](A-2) linear diphenylsiloxane-dimethylsiloxane copolymer based on a backbone composed of repeating diphenylsiloxane units and dimethylsiloxane units and containing 4 acryloxyethyloxy groups per molecule (two groups at each of the both ends of the molecular chain), represented by the formula (8), having a viscosity of 3,000 mPa·s

[0068][0069](A-3) linear polydimethylsiloxane based on a backbone composed of repeating dimethylsiloxa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| volume resistivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com